Method for treating acetic acid in acidic DMF and co-producing magnesium acetate and device thereof

A technology of magnesium acetate and crude magnesium acetate, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve the difficulty of secondary utilization of magnesium hydroxide waste, poor purity and stability of DMF, Affect the quality of sucralose and other issues, to achieve the effect of high industrial application value, improved purity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

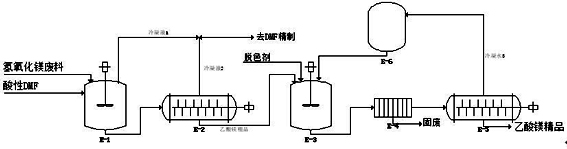

Image

Examples

Embodiment 1

[0028] The components of acidic DMF are shown in Table 1, and the components of magnesium hydroxide waste are shown in Table 2.

[0029] Table 1 Acidic DMF composition:

[0030] components DMF water Acetic acid Mass content / % 65 0 35

[0031] Table 2 Magnesium hydroxide waste composition:

[0032] components Mg(OH) 2

5-Ethyl-2(5H)-furanone Furfural water Mass content / % 89.98 0.01 0.01 10

[0033] A method for processing acetic acid in acidic DMF and co-producing magnesium acetate, the specific implementation steps are as follows:

[0034] Step (1): Add 1000kg of acidic DMF (see Table 1) into the neutralization kettle, the stirring rate is 150r / min, then add 188.0kg of magnesium hydroxide waste (see Table 2), after the addition is completed, the temperature is raised to 100°C, and the temperature is kept 15min; vacuumize after heat preservation, vacuum degree -0.05Mpa, temperature 80°C, remove one-third of DMF an...

Embodiment 2

[0043] The components of acidic DMF are shown in Table 5, and the components of magnesium hydroxide waste are shown in Table 6.

[0044] Table 5 Acidic DMF components

[0045] components DMF water Acetic acid Mass content / % 85 3 15

[0046] Table 6 Composition of magnesium hydroxide waste

[0047] components Mg(OH) 2

5-Ethyl-2(5H)-furanone Furfural water Mass content / % 69.85 0.1 0.05 30

[0048] A method for processing acetic acid in acidic DMF and co-producing magnesium acetate, the specific implementation steps are as follows:

[0049] Step (1): Add 500kg of acidic DMF to the neutralization kettle, the stirring rate is 300r / min, then add 51.9kg of magnesium hydroxide waste, after the addition is completed, the temperature is raised to 50°C, and the temperature is kept for 5min; -0.05Mpa, temperature 40°C, remove one-third of DMF and water, then transfer the material to rake dryer 1 to continue thickening, dryi...

Embodiment 3

[0056] The components of acidic DMF are shown in Table 9, and the components of magnesium hydroxide waste are shown in Table 10.

[0057] Table 9 Acidic DMF composition

[0058] components DMF water Acetic acid Mass content / % 79 1 20

[0059] Table 10 Composition of magnesium hydroxide waste

[0060] components Mg(OH) 2

5-Ethyl-2(5H)-furanone Furfural water Mass content / % 75 0.05 0.02 24.93

[0061] A method for processing acetic acid in acidic DMF and co-producing magnesium acetate, the specific implementation steps are as follows:

[0062] Step (1): Add 700kg of acidic DMF to the neutralization kettle, the stirring rate is 200r / min, then add 90.2kg of magnesium hydroxide waste, after the addition is completed, the temperature is raised to 80°C, and the temperature is kept for 10 minutes; -0.07Mpa, temperature 70°C, remove one-third of DMF and water, then transfer the material to rake dryer 1 to continue thicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com