Modification method suitable for electron accelerator equipment based on cobalt source radiation shielding device

A technology for electron accelerators and shielding devices, applied in irradiation devices, nuclear engineering, etc., can solve problems such as potential safety hazards, achieve low installation costs, increase the scope of application, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

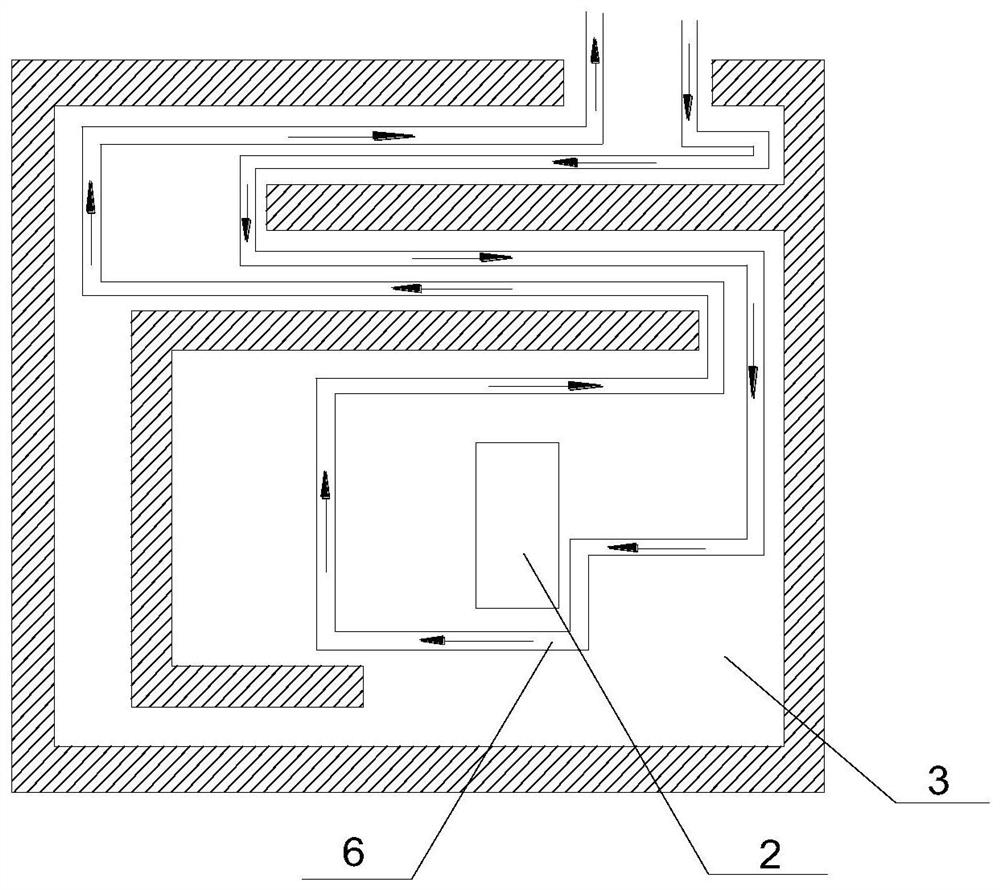

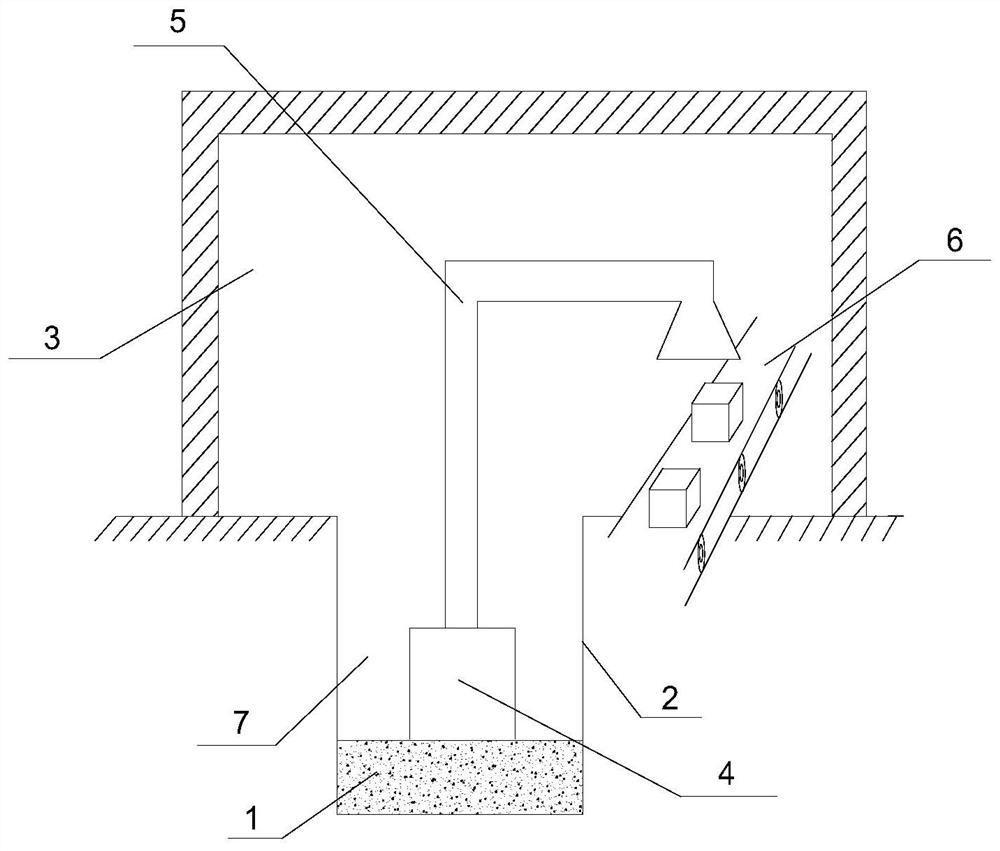

[0033] A modification method suitable for electron accelerator equipment based on a cobalt source radiation shielding device, comprising the following steps, step (1): using building materials 1 to partially fill the cobalt source water well 2, so that radiation is formed in the cobalt source water well 2 The cavity 7 and the cobalt source water well 2 are provided with a cobalt source irradiation chamber 3; step (2): the linear electron accelerator is fixed at the bottom of the cobalt source water well 2 or fixed and suspended in the irradiation cavity 7 via a steel plate, And the scanning window 5 is installed at the free end of the linear electron accelerator, and the scanning window 5 installed extends into the cobalt source irradiation chamber 3; Step (3): a conveying device 6 is provided on the ground, and the conveying device 6 is arranged along the The side wall of the cobalt source irradiation chamber 3 is set, and the scanning window 5 is located above the conveying d...

Embodiment 2

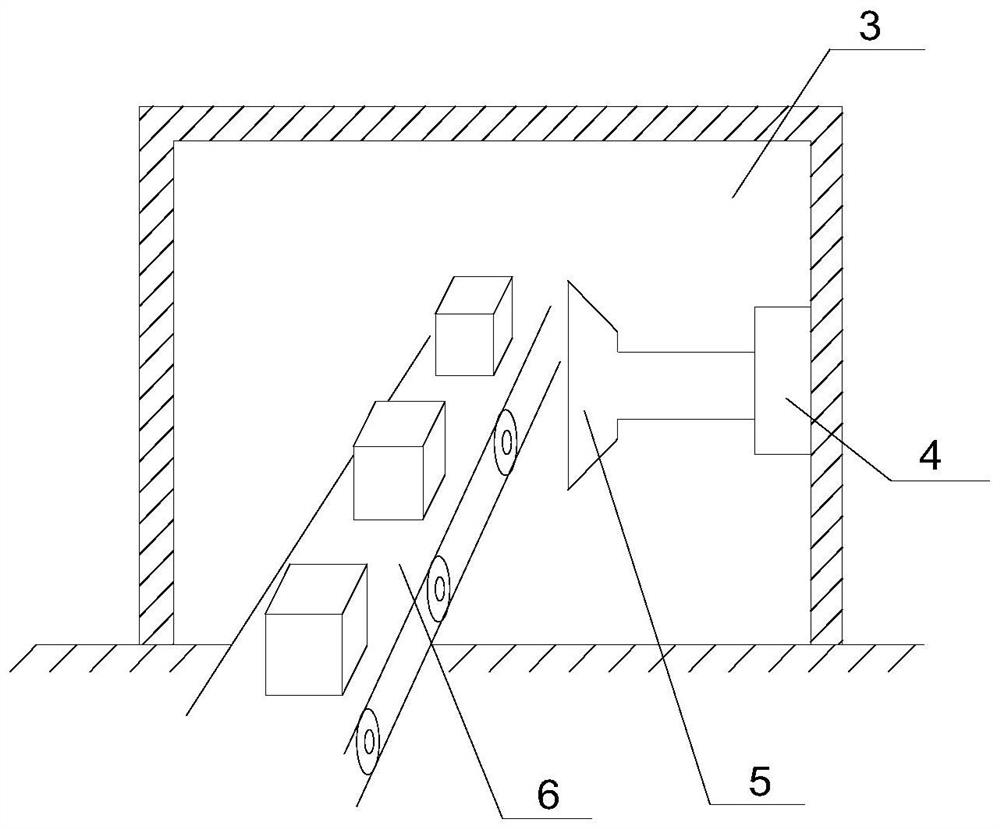

[0035] A modification method suitable for electron accelerator equipment based on a cobalt source radiation shielding device, comprising the following steps, step (1): use building materials 1 to fully fill the cobalt source water well 2, and set the cobalt source water well 2 with cobalt Source irradiation chamber 3; step (2): the linear electron accelerator is vertically fixedly installed on the inner wall of the cobalt source irradiation chamber 3, and a scanning window 5 is installed at the free end of the linear electron accelerator; step (3): on the ground A conveying device 6 is arranged on the top, and the conveying device 6 is arranged along the side wall of the cobalt source irradiation chamber 3, and the conveying direction of the conveying device 6 is perpendicular to the central axis of the scanning window 5, that is, the scanning window 5 is located on the conveying device. 6 side ends, such as image 3 The schematic diagram of the structure of the modified linea...

Embodiment 3

[0037] A modification method suitable for electron accelerator equipment based on a cobalt source radiation shielding device, comprising the following steps, step (1): use building materials 1 to fully fill the cobalt source water well 2, and set the cobalt source water well 2 with cobalt Source irradiation room 3; step (2): fixedly install the plum petal type electron accelerator on the top of the outer wall of the cobalt source irradiation room 3, and add a first shielding room 8 outside the plum petal type electron accelerator, and place the plum petal type electron accelerator The free end of the electron accelerator extends to the inside of the cobalt source irradiation chamber 3 and a scanning window 5 is installed; step (3): a conveying device 6 is provided on the ground, and the conveying device 6 is arranged along the cobalt source irradiation chamber 3 The side wall is set, and the scanning window 5 is located above the conveying device 6, such as Figure 4The schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com