Method for preparing hydrogen and LNG from coke oven gas

A technology of coke oven gas and hydrogen, applied in the direction of chemical instruments and methods, hydrogen, gas fuel, etc., can solve the problems of wasting precious resources, environmental pollution, etc., achieve huge economic and social benefits, reduce investment and operating costs, filter The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

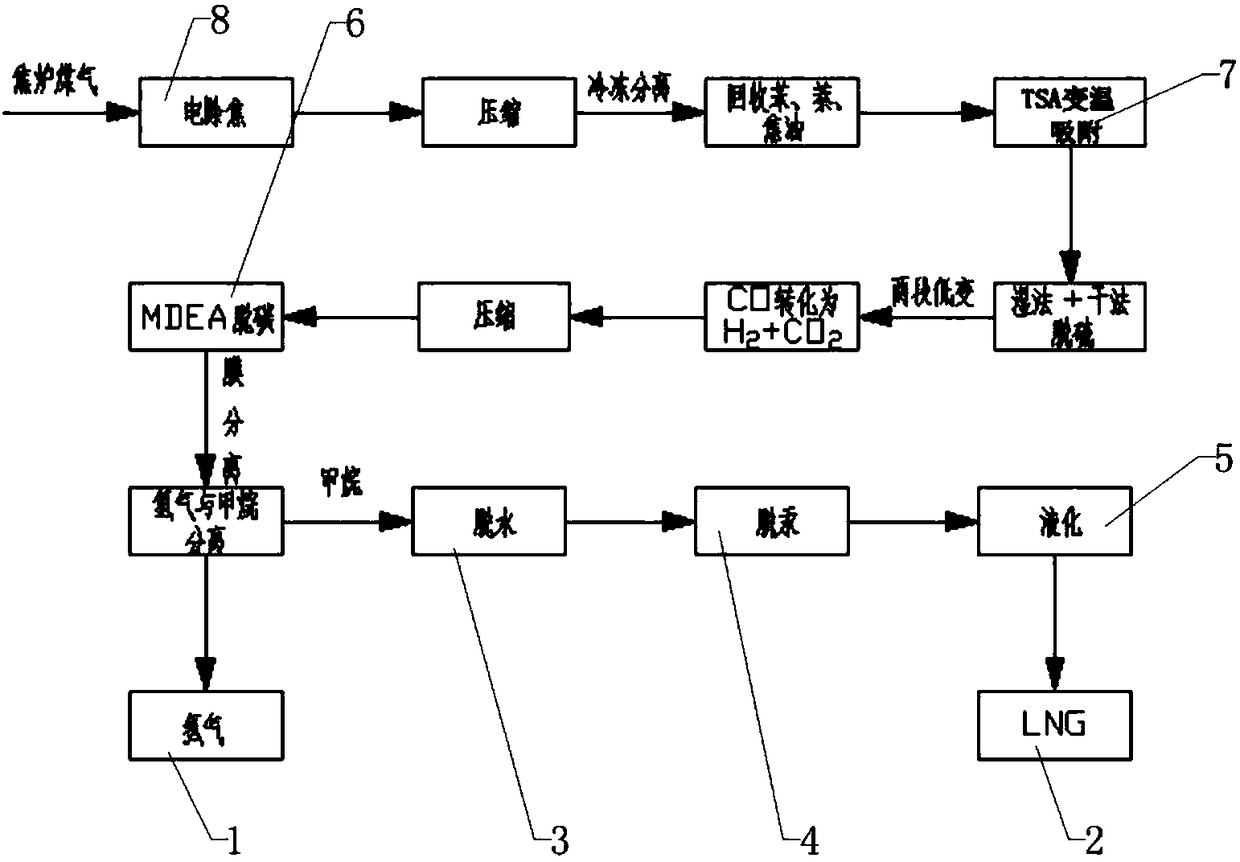

[0035] Example: as attached figure 1 Shown, a kind of coke oven gas produces the method for hydrogen and LNG, comprises the following steps:

[0036] (1) Electric decoking 8, using a tubular electric detarring device, the voltage used is selected from 40 to 60KV, and most of the tar, benzene, naphthalene and other liquid droplets and water particles in the raw material gas are removed in the high-voltage corona electric field;

[0037] (2) The compression system pressurizes the coke oven gas;

[0038] (3) Utilize BOG gas of LNG (the BOG gas refers to the gas after LNG is passively heated and gasified) to cool the raw coke oven gas, and further remove tar, benzene, naphthalene and other substances in the coke oven gas;

[0039] (4) Through the pretreatment of the TSA process, remove macromolecular impurities, such as tar, benzene, naphthalene, etc.;

[0040] (5) Two-stage desulfurization by wet method plus dry method to remove sulfide in coke oven gas;

[0041] (6) After two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com