Method for producing liquefied natural gas by using coke oven gas

A technology of liquefied natural gas and coke oven gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., and can solve problems such as risks that cannot cope with market changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is used to illustrate the method for producing liquefied natural gas from coke oven gas provided by the present invention.

[0037] The main composition (volume percentage) of raw coke oven gas is: 58%H 2 , 21%CH 4 , 9% CO, 5% N 2 , 4% CO 2 , 3%C m h n Wait.

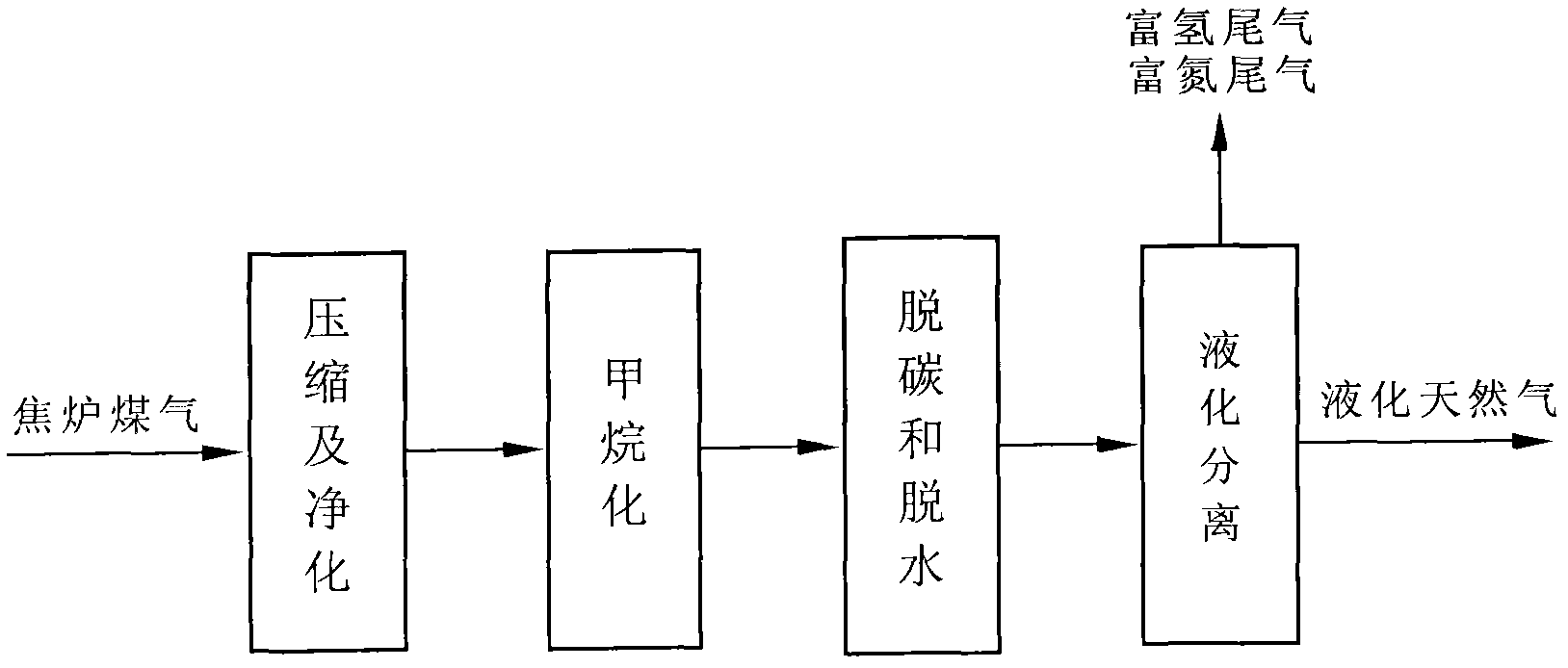

[0038] Such as figure 1 As shown, the raw coke oven gas is purified and compressed in the early stage to remove tar, benzene, naphthalene, sulfur and other impurities; then the methanation reaction is carried out to remove the CO and CO in the raw gas 2 with H 2 The reaction produces CH 4 , so as to increase the methane concentration of the feed gas, and then deCO2 the feed gas 2 and dehydration.

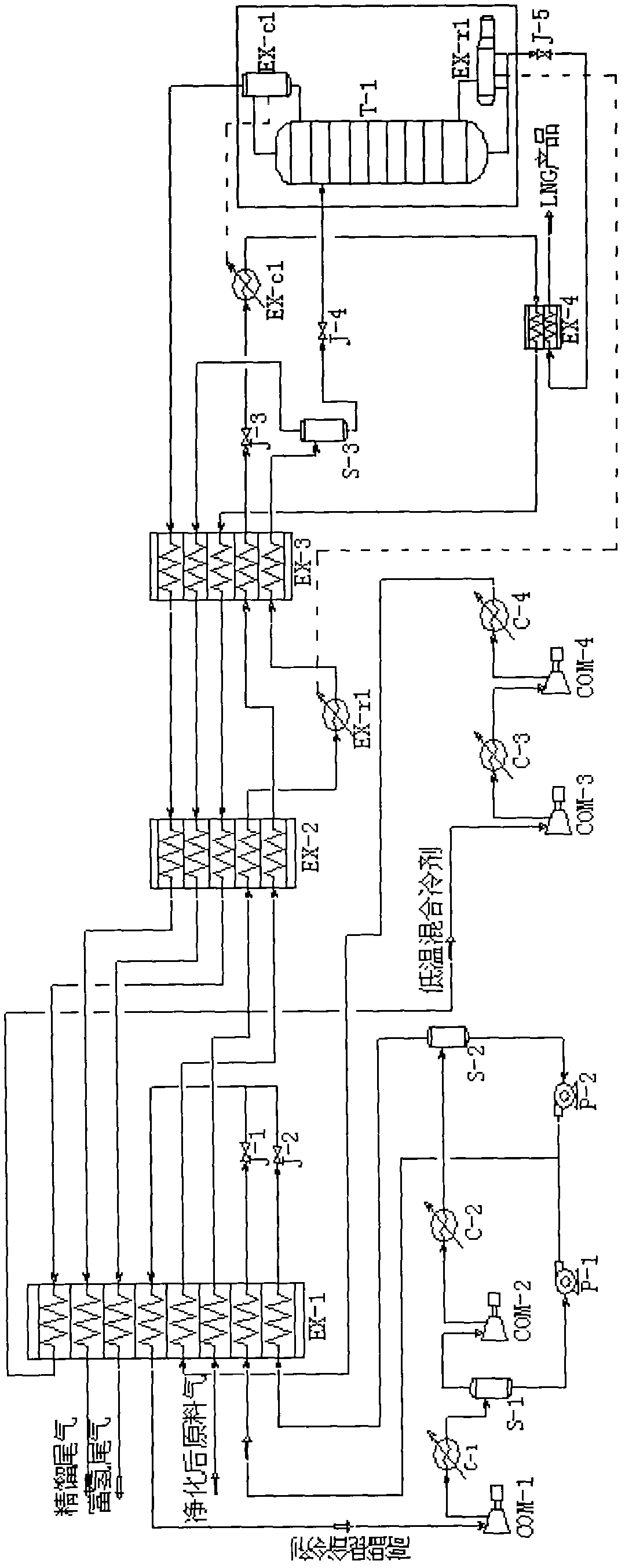

[0039] The specific operation method is: the coke oven gas is pressurized to 0.4MPa by the screw compressor and then enters the pretreatment process. The pretreatment adopts the temperature-swing-pressure-swing adsorption method to remove benzene, naphthalene, tar and HCN, using the hydrogen-rich...

Embodiment 2

[0049] This example is used to illustrate the method for producing liquefied natural gas from coke oven gas provided by the present invention.

[0050] According to the same method as Example 1, the difference is:

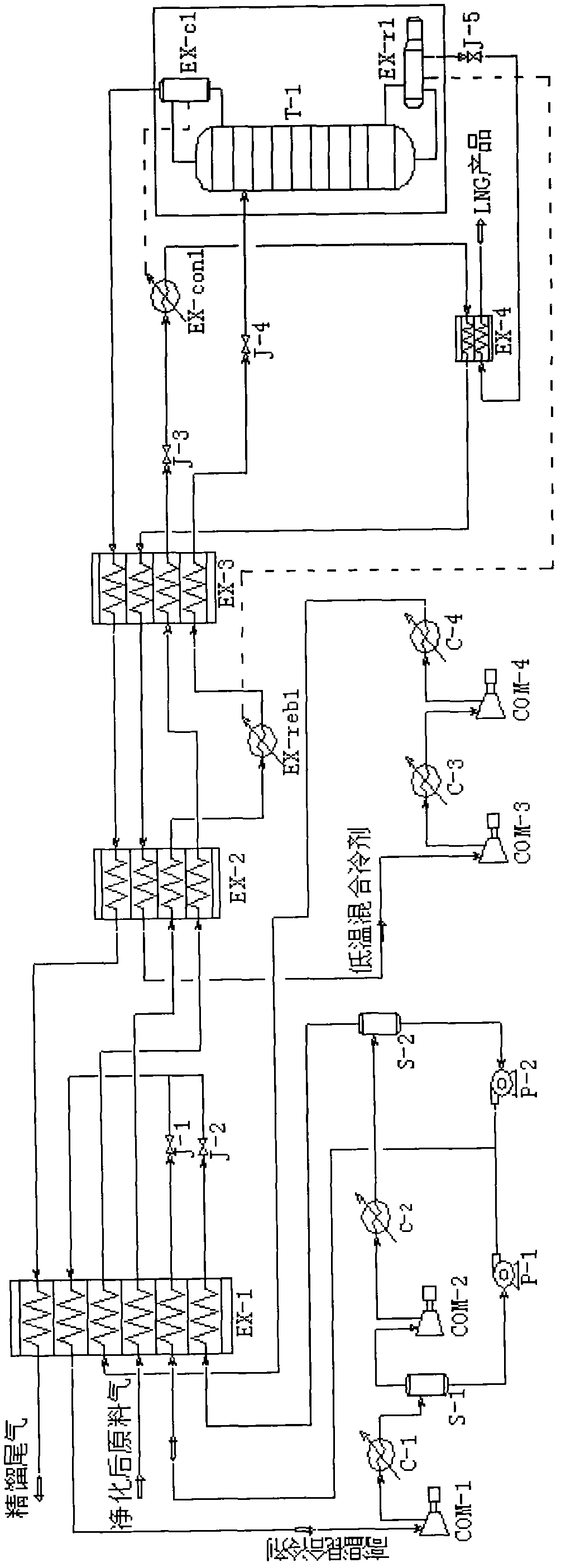

[0051] After the mixed refrigerant in the low temperature zone comes out from the hot end of the second heat exchanger EX-2, it does not enter the cold end of EX-1 as in Example 2, but directly returns to the first section of the compressor inlet COM-3 for compression (due to the -2 The mixed refrigerant coming out of the hot end is a low-temperature fluid with a temperature of -40 to -60°C, so the low-temperature mixed refrigerant compressor of this embodiment adopts a low-temperature compressor; while the low-temperature mixed refrigerant compressor of embodiment 1 adopts a Normal temperature compressor can be);

[0052] After the purified raw gas comes out from the cold end of the third heat exchanger EX-3, it directly enters the cryogenic rectification tower T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com