Process for preparing liquefied natural gas (LNG) and hydrogen from coke oven gas

A technology of coke oven gas and hydrogen, applied in hydrogen separation, gas fuel, petroleum industry, etc., can solve the problems of increasing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

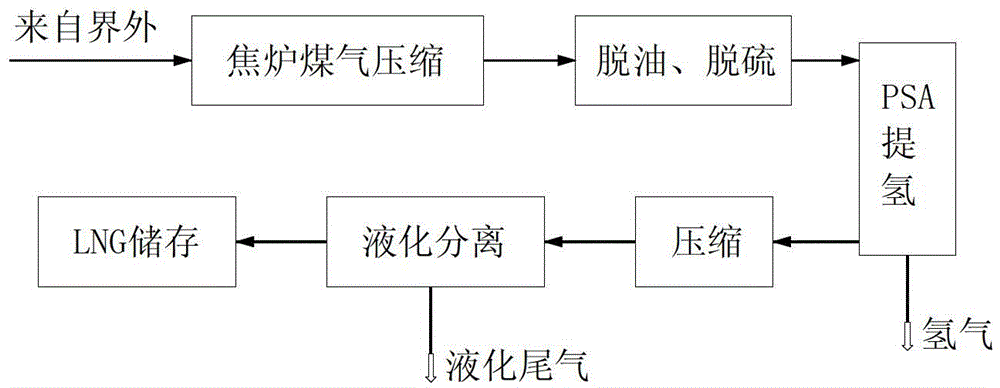

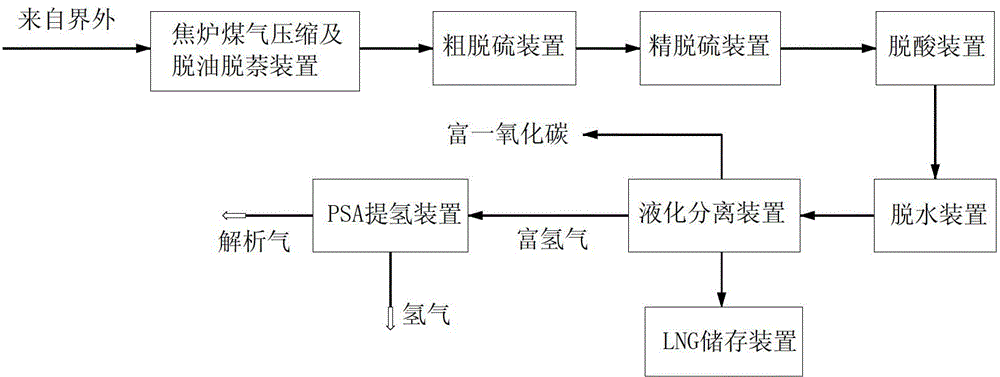

[0062] Process scheme of the present invention is as follows:

[0063] Such as figure 2 As shown, the coke oven gas from outside the boundary area undergoes compression, deoiling and naphthalene removal, crude desulfurization, hydroconversion fine desulfurization, deacidification (CO 2 ), dehydration, cryogenic liquefaction separation, PSA hydrogen extraction unit, complete the whole process.

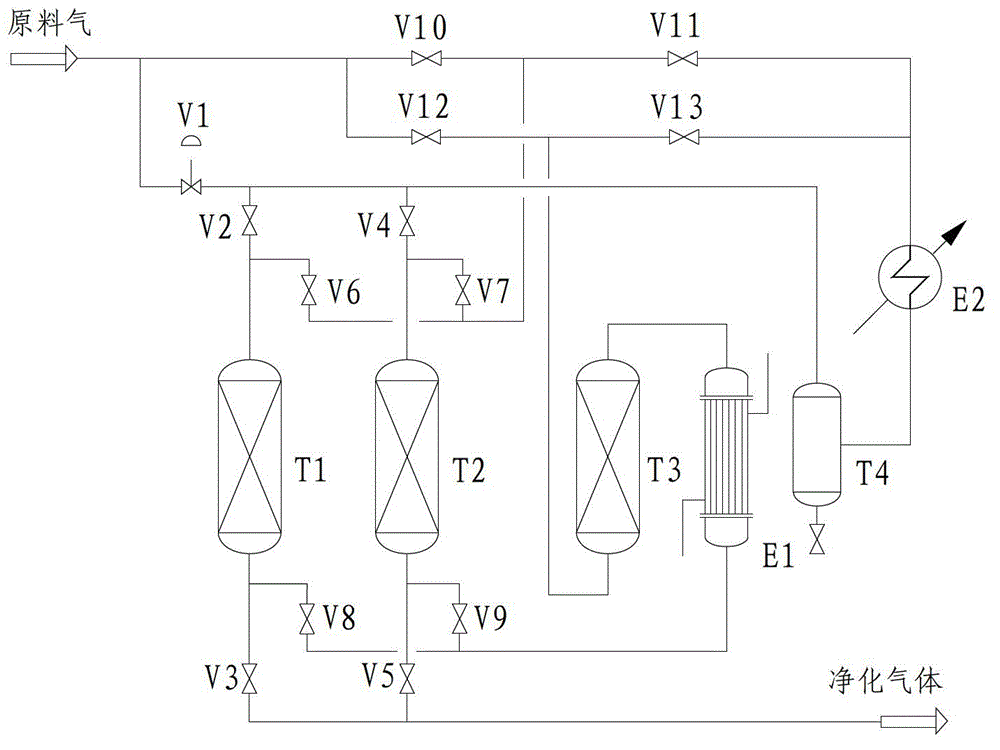

[0064] 1) Coke oven gas compression and deoiling and naphthalene removal

[0065] The coke oven gas (raw material gas) from outside the boundary area is compressed (for example, boosted to 0.1-0.5MPa) by a compressor (that is, the first-stage compressor) and enters the crude oil denaphthalene denaphthalene device for preliminary deoiling Naphthalene removal, and then through another compressor (that is, two-stage, or two-stage and three-stage compressor) to continue to increase the pressure (for example, to 0.45 ~ 3.0MPa) and enter the refined oil denaphthalene remover for further de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com