Method and apparatus for producing clean reducing gases from coke oven gas

a technology of reducing gas and coke oven, which is applied in the direction of combustible gas purification/modification, furnaces, separation processes, etc., can solve the problems of not teaching or suggesting a process and apparatus, the coke oven gas cleaning process requires a complex and costly chemical plant, and the patent does not teach or suggest a partial combustion. , to achieve the effect of avoiding the complex and expensive cleaning process

Inactive Publication Date: 2006-02-09

HYLSA SA DE CV

View PDF1 Cites 62 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0011] It is another object of the present invention to provide a process and system for treating coke oven gas and producing a synthesis gas useful as raw material in chemical processes or for producing heat, steam, electricity or power avoiding the complex and expensive cleaning processes normally utilized in coking plants.

Problems solved by technology

Cleaning of coke oven gas require's a complex and costly chemical plant.

This patent does not teach or suggest carrying out a partial combustion of coke oven gas for producing a high-quality reducing gas.

The partial combustion process of this patent however has a number of disadvantages and does not teach or suggest a process and apparatus which integrates the energy in an improved way.

Although this patent teaches generally that the coke oven gas may be used as a reducing gas in an iron ore reduction shaft furnace, no detail is provided about a preferred manner of utilizing the integration of the thermal energy that the coke oven gas contains.

This process scheme has a number of disadvantages since all equipment involved in the handling and conduction of the coke oven gas from the coke ovens to the shaft reactor must be prepared for high-temperature operation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

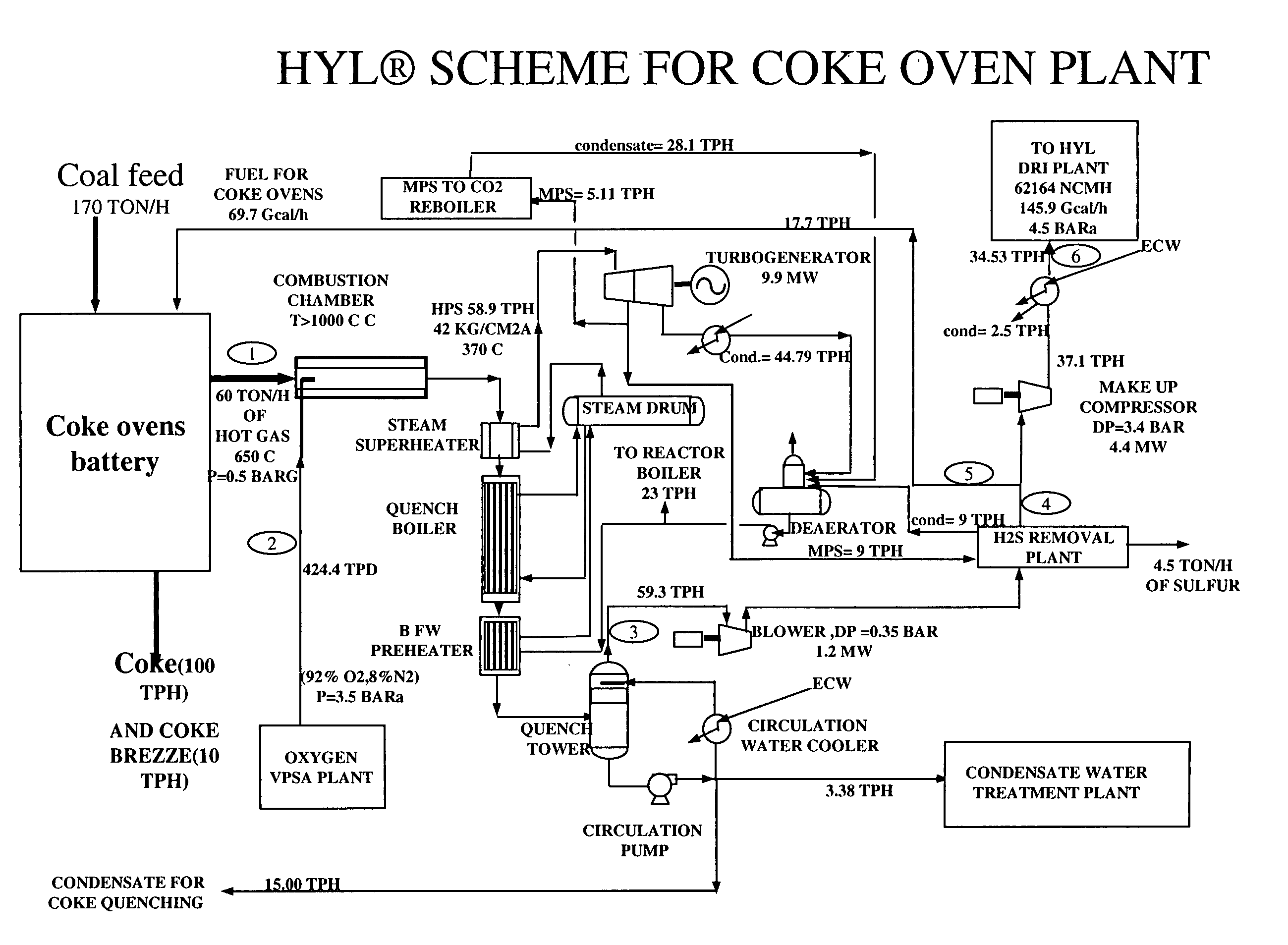

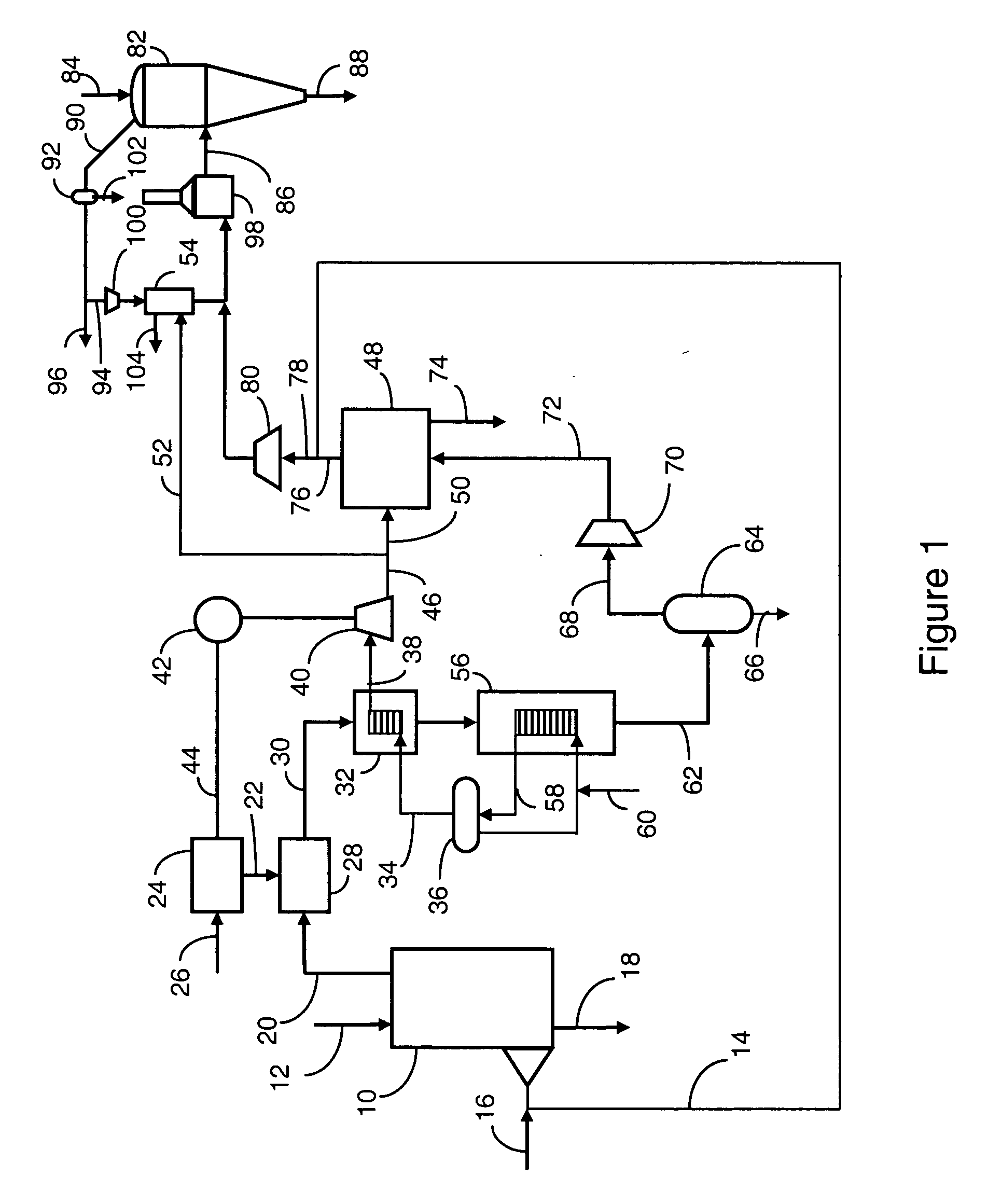

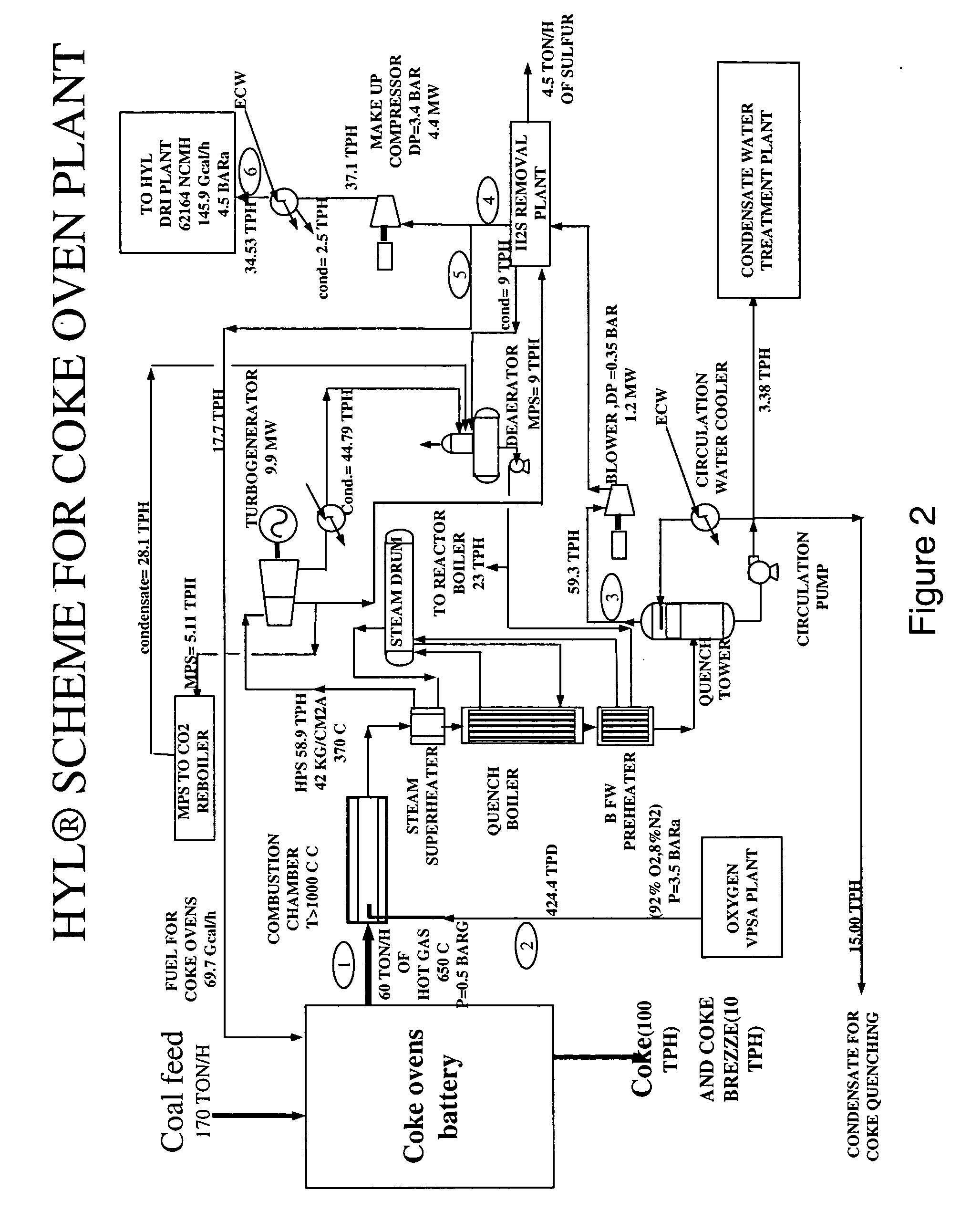

[0029] A computer-model calculation of a plant incorporating the invention was made and the results are illustrated in FIGS. 2, 3 and 4. This example clearly shows the advantages of the invention regarding its application for obtaining a reducing gas for producing good-quality direct reduced iron.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Login to View More

Abstract

A process and system for producing reducing gases are disclosed, wherein volatile components derived from coal are transformed into reducing gases suitable for utilization as synthesis gas, as a reducing agent for the direct reduction of iron ores and / or as a clean fuel.

Description

FIELD OF THE INVENTION [0001] The invention refers to a process and system for producing reducing gases mainly composed of hydrogen and carbon monoxide from coke-making operations where coal is transformed into metallurgical coke, and more particularly to a process wherein the volatile components derived from coal are transformed into reducing gases suitable for chemical utilization as synthesis gas, as a reducing agent for direct reduction of iron ores and / or as a clean fuel. BACKGROUND OF THE INVENTION [0002] It is known that in the process of producing metallurgical coke, coal is heated in order to eliminate most of the volatile components and preserving mostly the carbon structure. Coke is thereby provided with the physical and chemical properties which make it fit for providing energy and burden support in blast furnaces. Volatile matter of coal comprises a number of compounds which are distilled in coke ovens constituting what is known as coke oven gas. The volume and composit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): C21B13/02

CPCB01D53/48C21B2100/04C01B3/50C01B13/0248C01B2203/0255C01B2203/04C01B2203/0485C01B2203/06C01B2203/0894C01B2203/84C01B2210/0046C10J3/66C10J2300/1671C10K1/00C21B13/0073C21B13/02C21B2100/02C01B3/36C21B2100/282C21B2100/42C21B2100/60C21B2100/62C21B2100/66Y02P10/122Y02P10/134

Inventor ZENDEJAS-MARTINEZ, EUGENIO

Owner HYLSA SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com