Method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas

A technology of liquefied natural gas and coke oven gas, which is applied in the direction of gas fuel, combustible gas purification, combustible gas purification/transformation, etc., which can solve the problems of increased investment and operating costs, short operating life of equipment, and high reaction temperature, and achieve investment and operation The effect of cost reduction, investment and operating cost reduction, and reaction temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

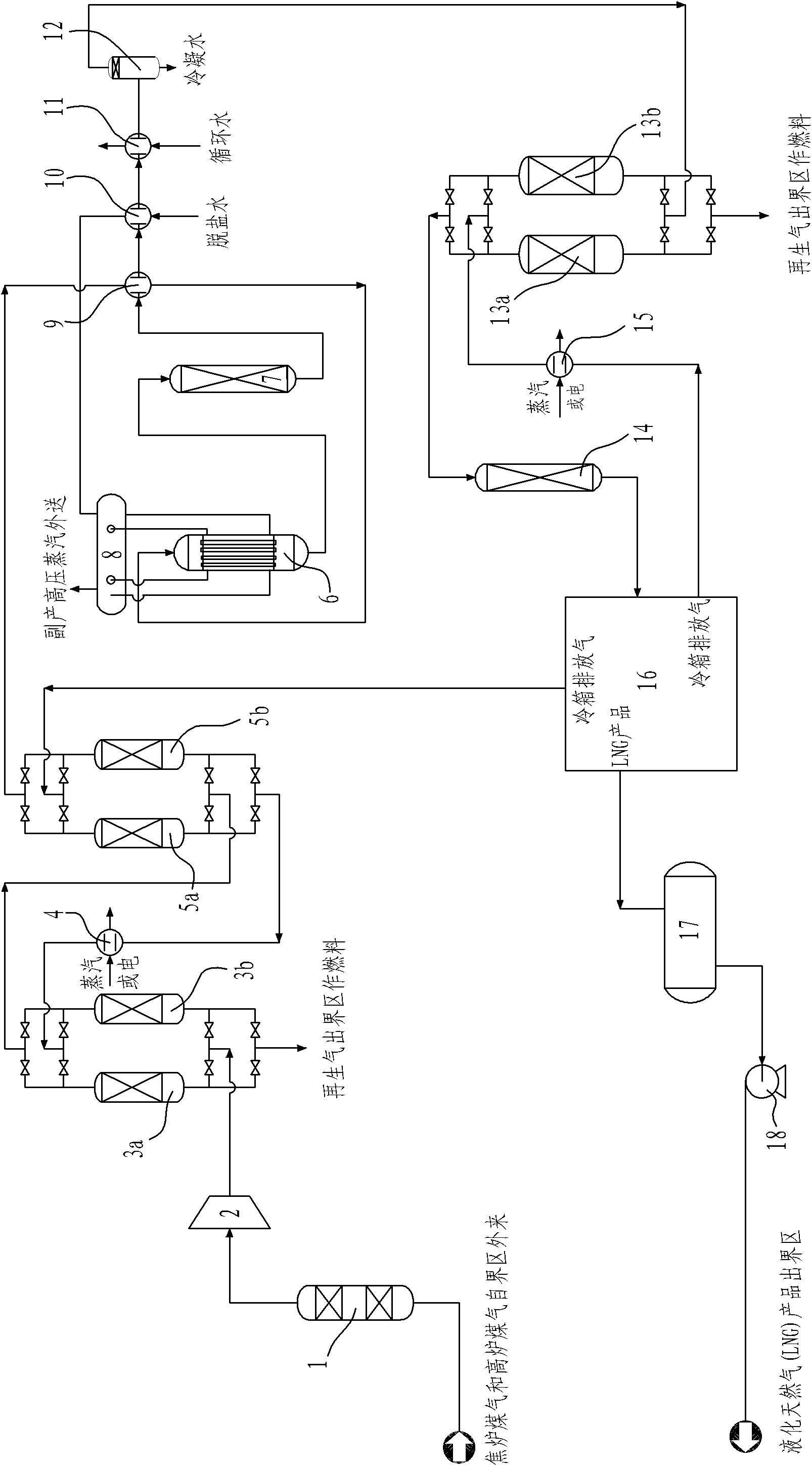

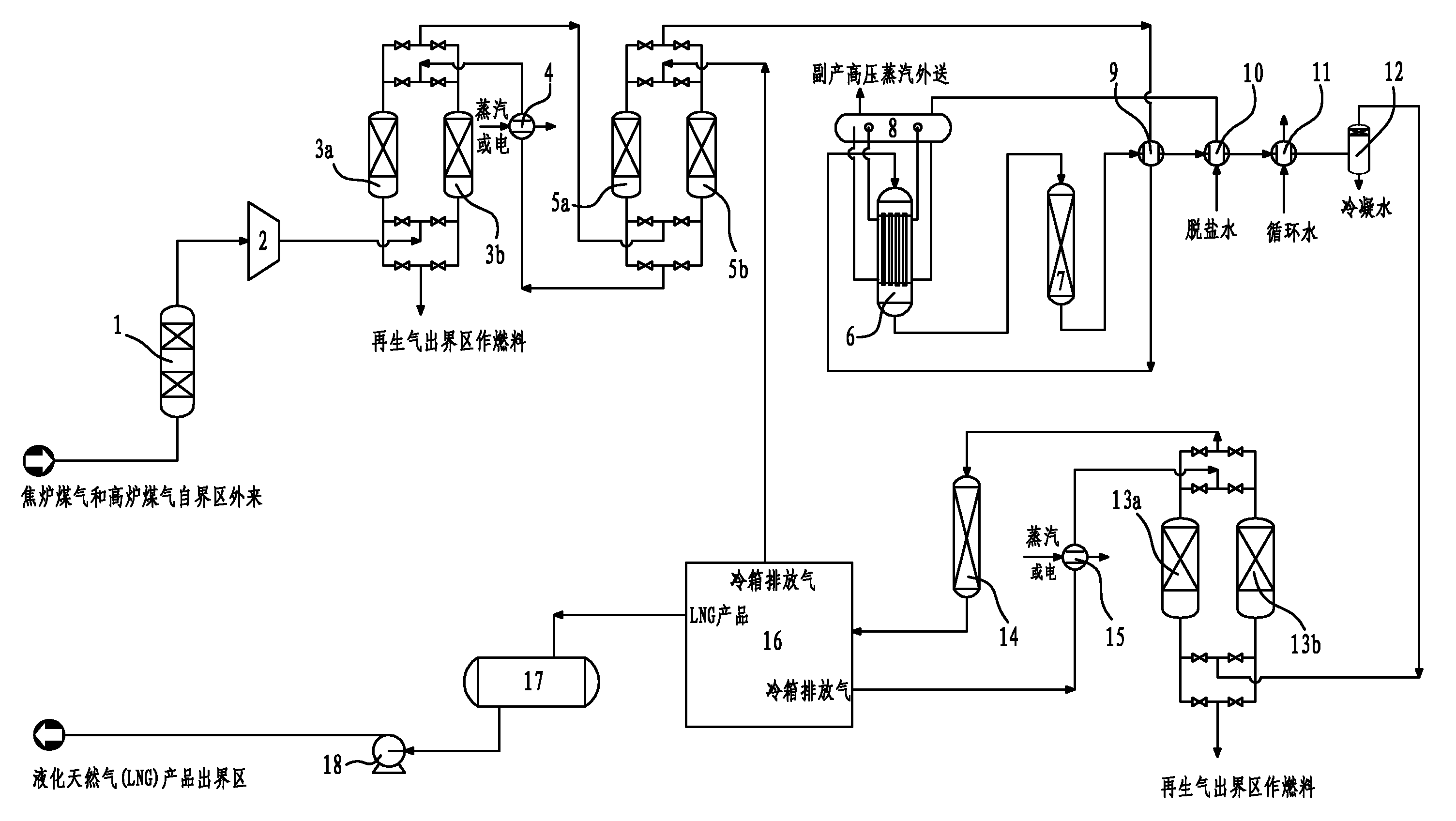

Method used

Image

Examples

Embodiment 1

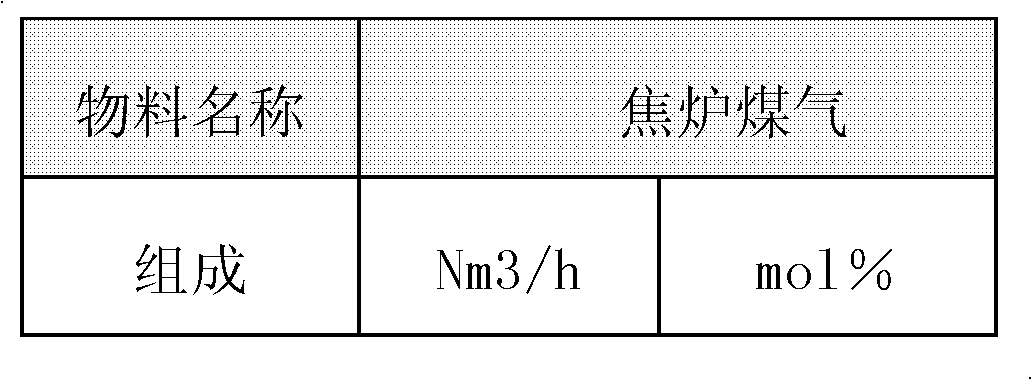

[0061] With coke oven gas 8500Nm 3 / h, the composition is as follows:

[0062]

[0063]

[0064] In order to produce more coke oven gas, add low-value 1700Nm 3 / h blast furnace gas, the composition is as follows:

[0065]

[0066]

[0067] After the two kinds of gas are mixed, they directly enter the desulfurization tower at a pressure close to normal pressure of 2KPa.G and a normal temperature of 40°C, and the H 2 S is removed below 10ppm, then enters the reciprocating gas compressor, compresses to 1.6MPa.G, and then enters the TSA+PSA adsorption purification process to remove naphthalene, tar, benzene, residual organic sulfur, inorganic sulfur, etc. in the gas All of them are removed by adsorption at one time to obtain a purified gas demethanization process with naphthalene<0.1ppm, tar<0.1ppm, benzene<1ppm, total sulfur<0.1ppm, pressure 1.5MPa.G, and temperature 40°C.

[0068]In the methanation process, through the isothermal-adiabatic series methanation react...

Embodiment 2

[0071] Also has coke oven gas 8500Nm 3 / h, the composition is as follows:

[0072]

[0073]

[0074] In the absence of blast furnace gas, only coke oven gas is used as raw material, and this technology can also be used.

[0075] At this time, the coke oven gas directly enters the desulfurization tower at a pressure of 2KPa.G and a normal temperature of 40°C, and the H 2 S is removed below 10ppm, then enters the reciprocating gas compressor, compresses to 1.6MPa.G, and then enters the TSA+PSA adsorption purification process to remove naphthalene, tar, benzene, residual organic sulfur, inorganic sulfur, etc. in the gas All of them are removed by adsorption at one time to obtain a purified gas demethanization process with naphthalene2 All converted to CH 4 , residual CO+CO 2 The content of 2 The content is 42.65 (v%), the pressure is 1.4MPa.G, the temperature is 40°C, and it enters the drying and demetallization process. After drying, the H2O content is less than 1ppm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com