Synthesis process of natural gas employing methanation of coke oven gas

A coke oven gas and natural gas technology, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of high energy consumption, large investment, and increased cost of synthetic natural gas, and achieve low energy consumption, improved energy utilization, and easy operation. Convenient, stable and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

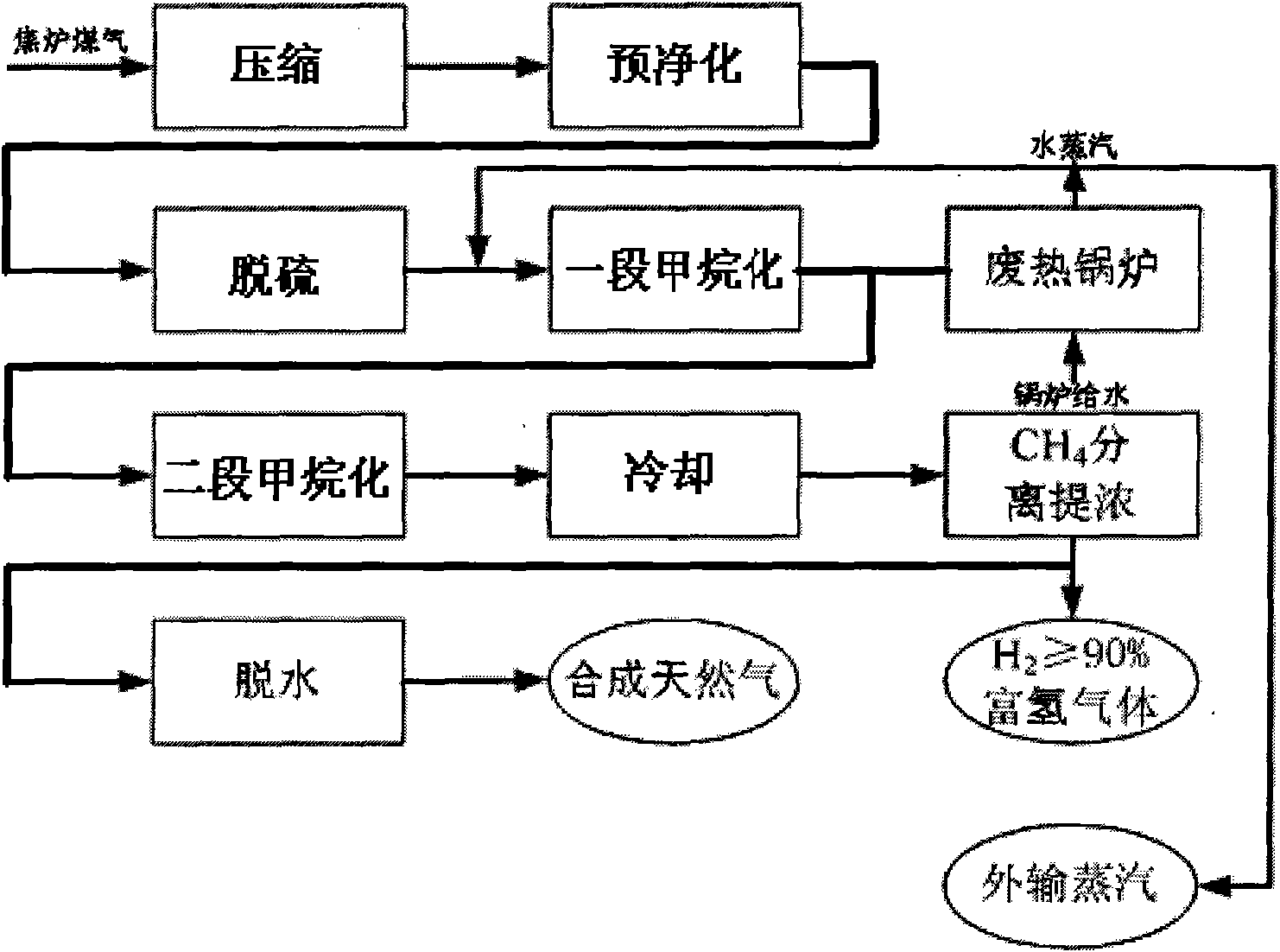

[0044] Such as figure 1 The coke oven gas methanation method shown to synthesize natural gas, coke oven gas 50000Nm 3 / h, compressed by a screw compressor to a reaction pressure of 0.3-0.49MPa, and then treated by absorption to remove ammonia, aromatics, tar and dust, and then enter medium-temperature hydrolysis to hydrolyze organic sulfur into H 2 S, then use wet desulfurization, and finally use dry fine desulfurization process to remove trace H 2 S, get pure coke oven gas. At this time, the composition of pure coke oven gas is H 2 : 54.4%, CH 4 : 28.2%, CO: 6.3%, CO 2 : 4.0%, N 2 : 3.1%, C m h n : 2.1%, total sulfur ≤0.1mg / Nm 3 , tar≤0.5mg / Nm 3 , Aromatics≤30mg / Nm 3 .

[0045] After the pure coke oven gas is preheated to 300°C, water steam is added. The amount of water steam added is 20% of the pure coke oven gas. After mixing, it enters the first-stage methanation reactor. Under the action of the methanation catalyst produced by Chemical Technology Co., Ltd., th...

Embodiment 2

[0050] Such as figure 1 The coke oven gas methanation method to synthesize natural gas shown, coke oven gas 20000Nm 3 / h, compressed by a reciprocating compressor to a reaction pressure of 0.5-0.8MPa, and then treated by adsorption to remove ammonia, aromatics, tar and dust, and then enter medium-temperature hydrolysis to hydrolyze organic sulfur into H 2 S, then use wet desulfurization, and finally use dry fine desulfurization process to remove trace H 2 S, get pure coke oven gas. At this time, the composition of pure coke oven gas is H 2 : 56.5%, CH 4 : 25.0%, CO: 5.9%, CO 2 : 2.8%, N 2 : 5.0%, C m h n : 3.0%, total sulfur ≤ 0.1mg / Nm 3 , tar≤0.5mg / Nm 3 , Aromatics≤30mg / Nm 3 .

[0051] After the pure coke oven gas is preheated to 250°C, water steam is added. The amount of water steam added is 30% of the pure coke oven gas, and it enters the first-stage methanation reactor with a reaction pressure of 0.5-0.8MPa. Under the action of the methanation catalyst produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com