Carbonization process of high-volatilize content coal

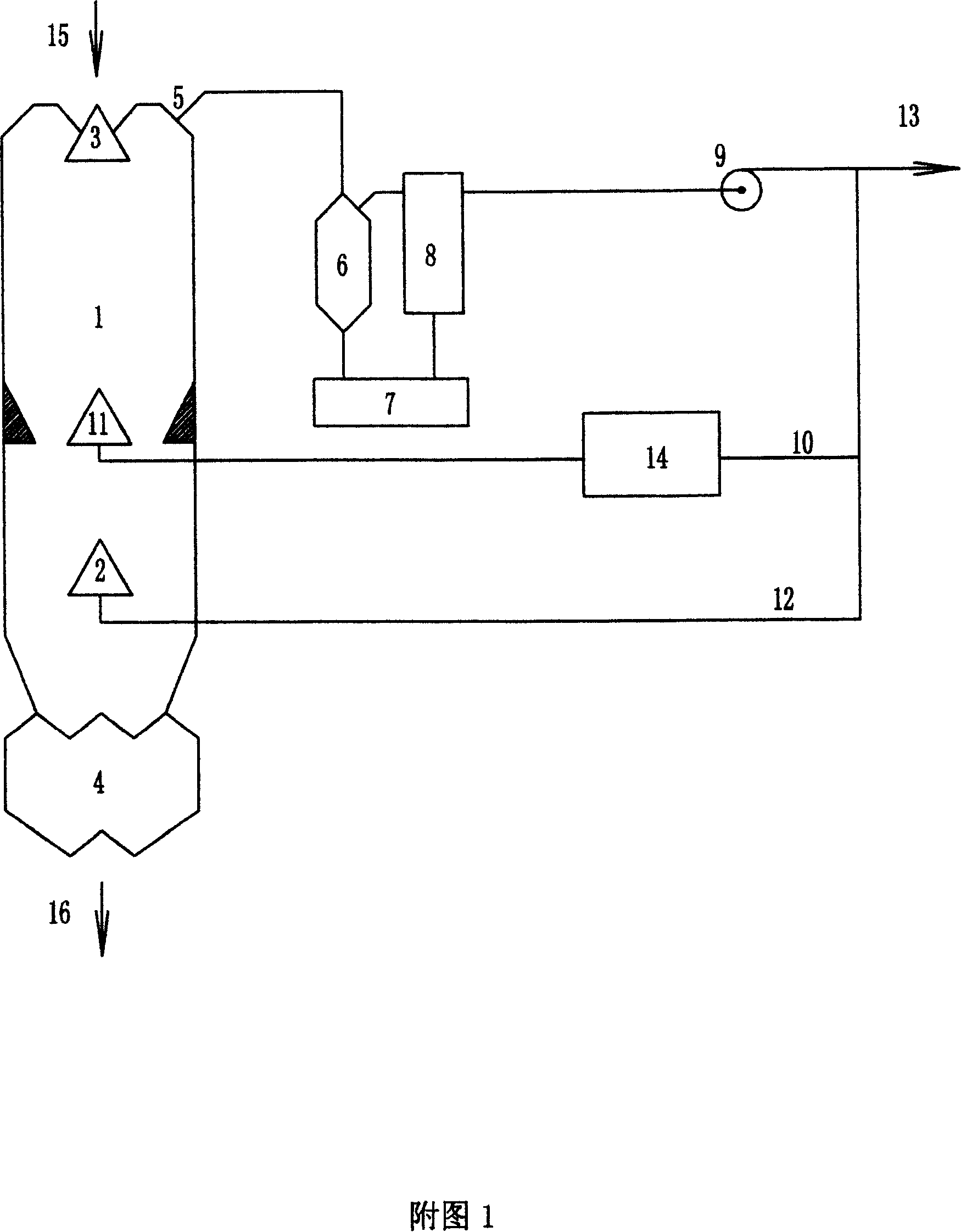

A high-volatile, dry distillation technology, used in direct heating dry distillation, petroleum industry, coke ovens, etc., can solve the problems of complicated equipment, and achieve the effect of simplifying equipment structure, high efficiency and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Based on 1000kg of lump coal, it is added from the top of the shaft furnace, and the preheated hot gas is introduced into the middle of the shaft furnace for 350m 3 (Temperature 1150°C), penetrate the falling coal seam, heat it and discharge volatiles, thus forming semi-coke, which continues to descend in the furnace, and introduces 550m from the bottom 3 The rising cold gas moves countercurrently, the cold gas takes away the heat in the semi-coke and merges it into the gas, and the semi-coke is cooled and released from the oven, weighing 600kg, and producing raw gas of 1310m at the same time 3 , exported from the top of the furnace, after cleaning and purification, part of it is preheated to 1150°C in the regenerator and used as heat carrier for dry distillation, part of it is introduced from the bottom of the furnace as a cooling medium for hot semi-coke, and the remaining 300m3 is used as commercial gas for external supply. And recover tar 20kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com