Iridium-based catalyst supported by acid-treated carbon carrier, and preparation method and application thereof

A catalyst and acid treatment technology, applied in physical/chemical process catalysts, carbon monoxide or formate reaction preparation, chemical instruments and methods, etc., can solve the problems of low selectivity, low space-time yield, and deactivation of molecular sieve carbon deposits. , to achieve the effect of high selectivity, low methane content and reduced selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

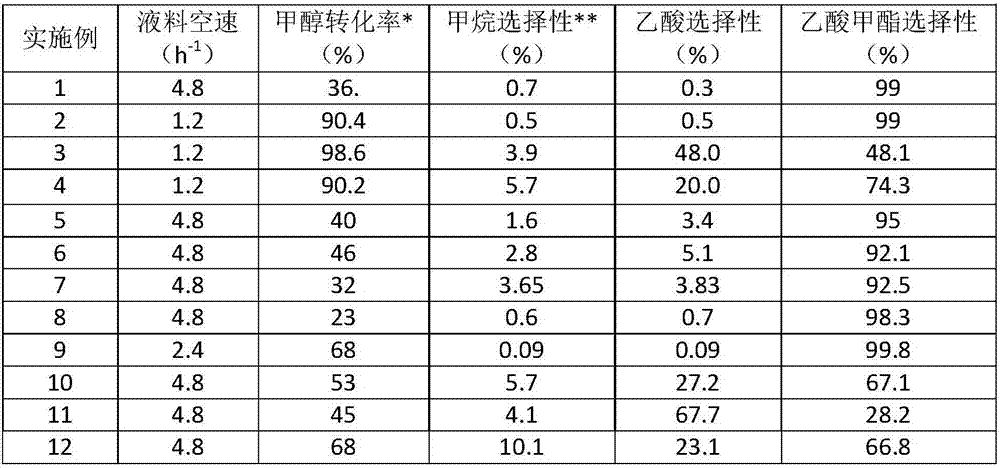

Examples

Embodiment 1

[0027] Weigh 8g of activated carbon, add 50ml of 1mol / L dilute nitric acid, cook at 60°C for 3 hours, wash with deionized water until neutral, and dry in an oven at 120°C to obtain acid-treated activated carbon. Weigh 3mL concentrated HCl and add 0.0128gLa 2 o 3 Stir until dissolved, then add 2.1ml of HCl with a concentration of 0.019g / mL to 3mL of hydrochloric acid solution 2 IrCl 6 ·6H 2 O aqueous solution, and then impregnated 1.5 g of the above-mentioned acid-treated coconut shell charcoal. Evaporate the solvent in a water bath at 80°C, dry in an oven at 120°C for 10 hours, and roast at 350°C under nitrogen protection for 4 hours to obtain an acid-treated iridium-based catalyst supported on a carbon carrier.

Embodiment 2

[0029] Weigh 8g of activated carbon, add 50ml of 1mol / L dilute nitric acid, cook at 60°C for 3 hours, wash with deionized water until neutral, and dry in an oven at 120°C to obtain acid-treated activated carbon. Then take 4.5g of the activated carbon from the previous step and react with 50ml of concentrated sulfuric acid at 180°C for 10h, wash with hot deionized water until neutral and free of sulfate ions, and oven-dry at 120°C to obtain sulfonic acid-treated activated carbon. Weigh 4mL concentrated HCl and add 0.0298gLa 2 o 3 Stir until dissolved, then add 4.943ml of HCl with a concentration of 0.019g / mL to 4mL of hydrochloric acid solution 2 IrCl 6 ·6H 2 O aqueous solution, and then impregnated 4 g of the above acid-treated activated carbon. Evaporate the solvent in a water bath at 80°C, dry in an oven at 120°C for 10 hours, and roast at 350°C under nitrogen protection for 4 hours to obtain an acid-treated activated carbon-supported iridium-based catalyst.

Embodiment 3

[0031] Weigh 4g of activated carbon and 50ml of concentrated sulfuric acid to react at 180°C for 10h, wash with deheated deionized water until neutral and free of sulfate ions, and dry in an oven at 120°C to obtain sulfonic acid-treated activated carbon. Weigh 3mL concentrated HCl and add 0.0213gLa 2 o 3 Stir until dissolved, then add 3.467ml of HCl with a concentration of 0.019g / mL to 3mL of hydrochloric acid solution 2 IrCl 6 ·6H 2O aqueous solution, then impregnated 2.5 g of the above acid-treated coconut shell charcoal. Evaporate the solvent in a water bath at 80°C, dry in an oven at 120°C for 10 hours, and roast at 350°C under nitrogen protection for 4 hours to obtain an acid-treated activated carbon-supported iridium-based catalyst

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com