C4 fraction catalytic onversion method for yielding propylene

A technology of C4 fraction and propylene, applied in the field of catalytic conversion, can solve problems such as reducing the yield of dry gas, and achieve the effects of taking into account the heat balance, the increase of the conversion rate, and the increase of the yield of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

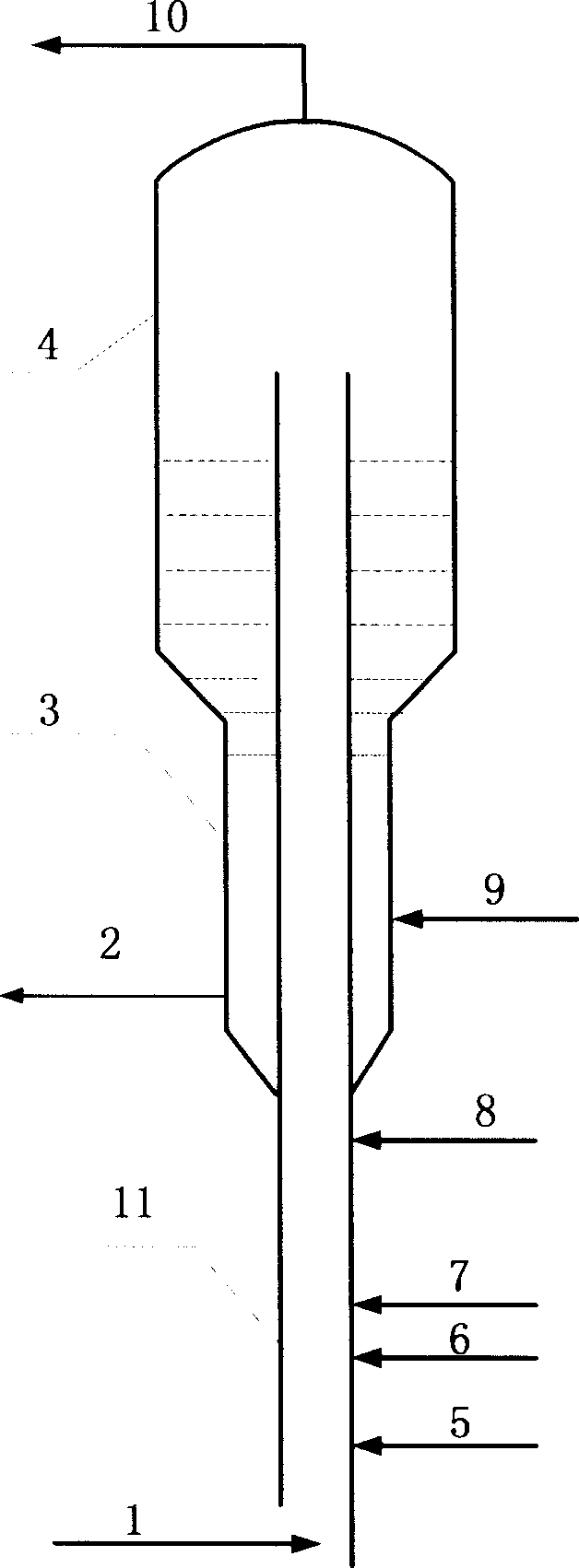

Image

Examples

Embodiment 1

[0034] In this example, the C4 fraction rich in olefins is used as the raw material, and the BBC-3 catalyst with a pre-coke amount of 0.25% is used, and the test results of the single-pass catalytic conversion are carried out in two stages in a small fluidized bed reactor.

[0035] As shown in Table 1, the olefin-rich C4 fraction first enters the fluidized bed reactor, and at a reaction temperature of 620 ° C, it is contacted with a BBC-3 catalyst with a pre-coke amount of 0.25% to activate stripping, collect and analyze The reaction product does not undergo coke regeneration of the catalyst, but continues to pass through the C4 fraction shown in Table 1 to contact the catalyst for reaction. The reaction product, steam and spent agent are separated in the settler, and the reaction product is separated to obtain gas product and liquid product, while the spent catalyst is stripped by water vapor to remove the hydrocarbon product adsorbed on the spent agent. The stripped spent ag...

Embodiment 2

[0042] In this example, the C4 fraction rich in olefins is used as the raw material, and the BBC-3 catalyst with a pre-coke content of 0.36% is used, and the experimental results of the single-pass catalytic conversion are carried out in two stages in a small fluidized bed reactor.

[0043] The C4 fraction rich in olefins as shown in Table 1 first enters the fluidized bed reactor, and is contacted with the BBC-3 catalyst with a pre-coke amount of 0.36% to activate the stripping at a reaction temperature of 620 ° C, collect and The reaction product was analyzed, and the coke regeneration of the catalyst was not carried out, but the C4 fraction shown in Table 1 was continued to be introduced into the catalyst for contact reaction. The reaction product, steam and spent agent are separated in the settler, and the reaction product is separated to obtain gas product and liquid product, while the spent catalyst is stripped by water vapor to remove the hydrocarbon product adsorbed on t...

Embodiment 3

[0051] In this example, the C4 fraction rich in olefins is used as the raw material, and the BBC-3 catalyst with a pre-coke amount of 0.55% is used, and the catalytic conversion is carried out in two stages in a small fluidized bed reactor.

[0052] As shown in Table 1, the olefin-rich C4 fraction first enters the fluidized bed reactor, and at a reaction temperature of 620 ° C, it contacts with a BBC-3 catalyst with a pre-coke amount of 0.55% to activate stripping, collect and analyze The reaction product does not undergo coke regeneration of the catalyst, but continues to pass through the C4 fraction shown in Table 2 to contact the catalyst for reaction. The reaction product, steam and spent agent are separated in the settler, and the reaction product is separated to obtain gas product and liquid product, while the spent catalyst is stripped by water vapor to remove the hydrocarbon product adsorbed on the spent agent. The stripped spent agent was regenerated in contact with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com