Hydration, pressure swing adsorption and deep cooling combined process for separating ethene cracking gas

A combined process and pressure swing adsorption technology, which is applied in the purification/separation of hydrocarbons, hydrocarbons, hydrocarbon cracking and hydrocarbon production, etc., can solve the problems of no more reports, reduce production energy consumption and cost input, and reduce The cooling load at the top of the tower and the effect of reducing the overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

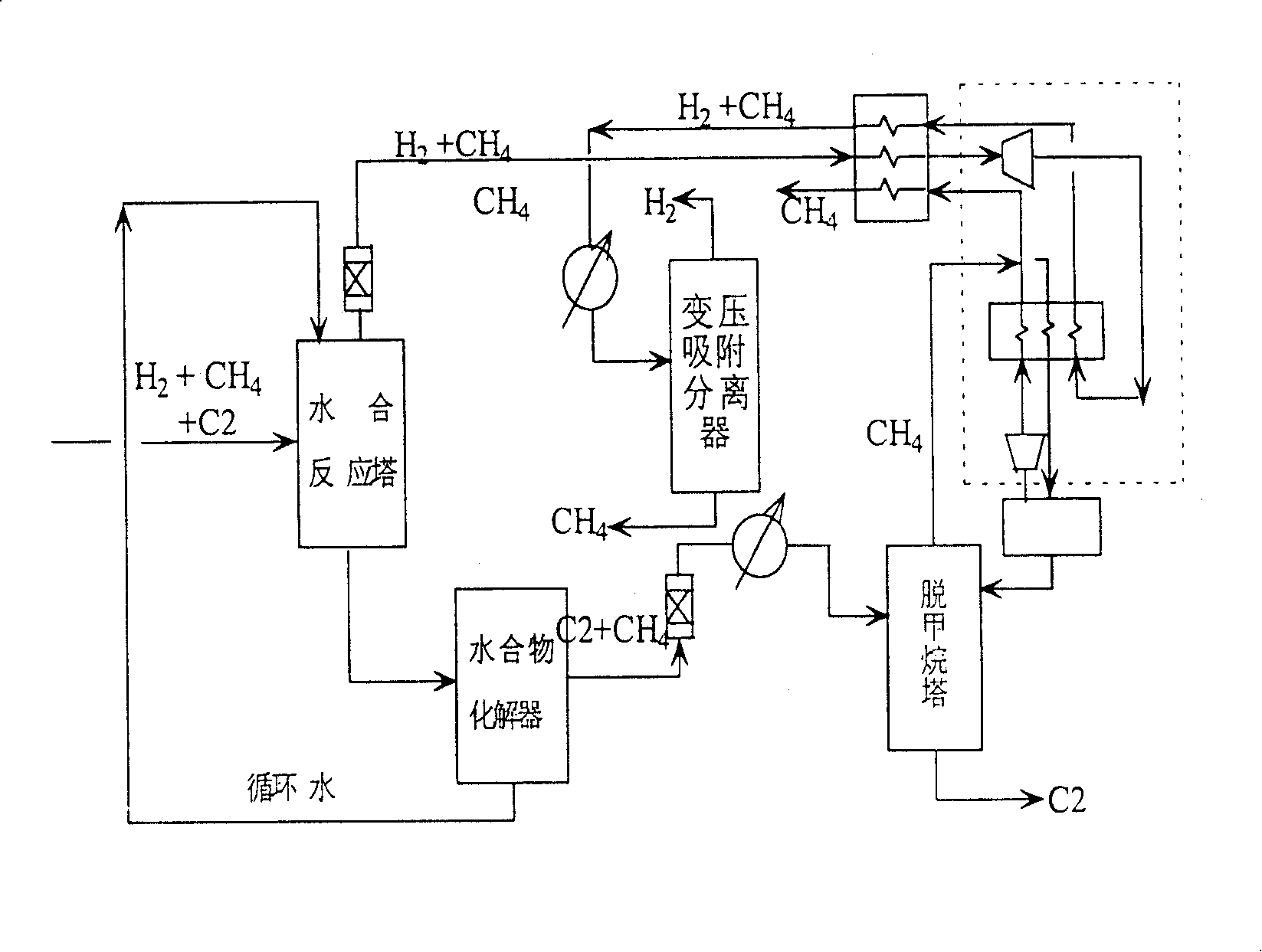

[0029] Example 1. Analysis of the separation effect and energy consumption of ethylene cracking gas in the combined process of hydration separation + pressure swing adsorption separation + cryogenic separation

[0030] In this embodiment, the simulated ethylene cracking gas is separated according to the combined process flow of the present invention, the separation effect data is recorded, and the heat energy consumption in the process is analyzed.

[0031] Simulated ethylene cracking gas (feed gas) stream composition (mol%):

[0032] h 2 , 19.85%; CH 4 , 42.78%; C 2 h 4 , 33.78%; C 2 h 6 , 2.41%; C 3 h 6 , 0.35%.

[0033] Specific process flow:

[0034] The cracked gas stream to be separated (the pressure of the cracked gas at this time is about 3.6 MPa) is first sent into the hydration reactor, which is a hydration reaction tower capable of multi-stage separation in this embodiment. The operating conditions of the hydration reaction tower are: temperature 1°C, pres...

Embodiment 2

[0049] Embodiment 2, the single-stage hydration separation of the water liquid separation ethylene cracking gas containing SDS (500ppm)

[0050] Hydration reaction conditions: T=275.15K, P=3MPa, gas-water volume ratio is 75:1.

[0051] Experimental method: The cracked gas mixture to be separated and the water-containing liquid are contacted in a high-pressure reactor to form hydrates. During the reaction process, the reaction temperature and pressure were kept constant, and when the reaction reached equilibrium, the composition of the gas phase and the composition of the gas released after the dissolution of the hydrate were analyzed respectively.

[0052] The composition of the gas released after the hydrate is dissolved is the dry basis composition of the hydrate phase (the composition of the gas after deducting the amount of water).

[0053] Table 1. Single-stage hydration separation effect of water-liquid separation of ethylene cracking gas containing SDS (500ppm)

[005...

Embodiment 3

[0055] Embodiment 3, the single-stage hydration separation of ethylene cracking gas separation when the water-containing liquid adopts the emulsion of water+diesel

[0056] Hydration reaction conditions: T=274.15K, P=5MPa, oil-water volume ratio is 2:1, emulsifier Span 20 is used to make a water-in-oil emulsion system, and the gas-liquid volume ratio entering the hydration reaction tower is 75:1;

[0057] The experimental method is the same as in Example 2.

[0058] Table 2. The single-stage hydration separation effect of separating ethylene cracking gas when the water-containing liquid adopts water+diesel oil emulsion

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com