Method for coupling hydrocarbon steam cracking sequential separation process and propane dehydrogenation process

A technology of sequential separation and propane dehydrogenation, which is used in the purification/separation of hydrocarbons, hydrocarbon cracking to produce hydrocarbons, and hydrocarbons, etc. It can solve the optimization application of the deoiling tower of the propane dehydrogenation unit, the increase of the cooling load, and the separation energy. In order to improve the economic benefits of the device, reduce the construction land, and improve the propylene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the specific embodiments do not limit the scope of protection claimed by the present invention.

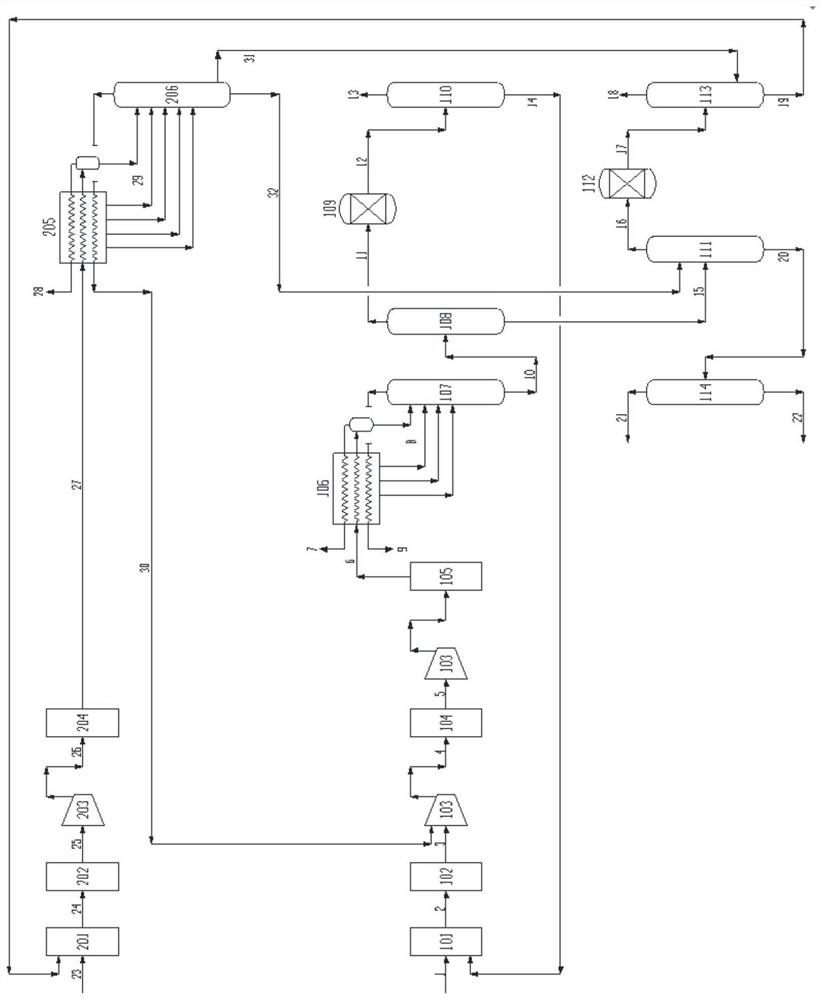

[0037] Such as figure 1 As shown, the hydrocarbon cracking raw material 1 is heated with the circulating ethane 14 from the ethylene rectification tower 110, and then enters the cracking unit 101 for steam thermal cracking reaction, and the cracked product 2 is generated and sent to the quenching unit 102, and separated by oil cooling and water cooling Cracked gas 3 is obtained after heavy hydrocarbons are produced. The cracked gas 3 is mixed with the non-condensable gas 30 from the top of the light component removal tower 206 and enters the cracked gas compression unit 103, and the boosted mixed gas 4 is deacidified by the alkali cleaning unit 104 to be a refined gas 5, and then the After being compressed, it enters the cracked gas dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com