Method for preparing isopropyl mercaptan

A technology of isopropyl mercaptan and propylene, which is applied in the field of preparation of isopropyl mercaptan, can solve the problems of high equipment requirements, low yield of isopropyl mercaptan, difficult treatment, etc., and achieve comprehensive utilization of resources and easy industrial transformation , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

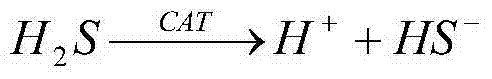

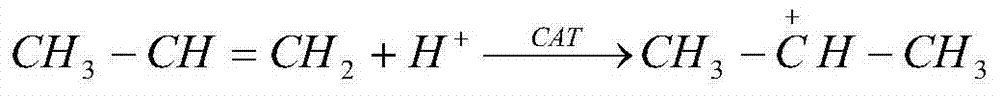

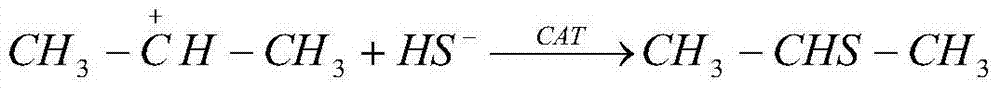

Method used

Image

Examples

Embodiment 1

[0053] Hydrogen sulfide and propylene are fully mixed at a molar ratio of 1:1, pressurized to 0.2MPa by a compressor, and heated to 160°C by a heating furnace, according to the propylene volume space velocity of 400h -1 , into an adiabatic fixed-bed reactor equipped with a solid acid catalyst for reaction, the catalyst used is composed of 1% molybdenum oxide, 1% cobalt oxide, 5% ZSM-5 molecular sieve, and the rest is alumina carrier , the ZSM-5 molecular sieve has a silicon-aluminum molar ratio of 10, a grain size of 5 μm, a pore volume of 0.4ml / g, and a specific surface area of 137m 2 / g. The reaction effluent is cooled to 25°C by heat exchange, the gas phase is returned to the hydrogen sulfide feed, and the liquid phase is fractionated to obtain four products, isopropyl mercaptan, n-propylene mercaptan, isopropyl sulfide and n-propyl sulfide. Among them, the single-pass conversion rate of propylene is 80.2%, the selectivity of isopropyl mercaptan is 89.4%, and the total y...

Embodiment 2

[0058] Hydrogen sulfide and propylene are fully mixed at a molar ratio of 2:1, pressurized to 0.2MPa by a compressor, and heated to 180°C by a heating furnace, according to the propylene volume space velocity of 300h -1 , into an adiabatic fixed-bed reactor equipped with a solid acid catalyst for reaction, the catalyst used is composed of 5% molybdenum oxide, 2% nickel oxide, 2% phosphorus pentoxide, 5% ZSM-5 molecular sieve, and the rest is alumina carrier , the ZSM-5 molecular sieve has a silicon-aluminum ratio of 20, a grain size of 5 μm, a pore volume of 0.3ml / g, and a specific surface area of 141m 2 / g. The reaction effluent is cooled to 20°C by heat exchange, the gas phase is returned to the hydrogen sulfide feed, and the liquid phase is subjected to fractional distillation to obtain four products, isopropyl mercaptan, n-propylene mercaptan, isopropyl sulfide and n-propyl sulfide. Wherein the single-pass conversion rate of propylene is 86.3%, the selectivity of isopro...

Embodiment 3

[0063] Hydrogen sulfide and propylene are fully mixed at a molar ratio of 3:1, pressurized to 0.25MPa by a compressor, and heated to 200°C by a heating furnace, according to the propylene volume space velocity of 300h -1 , into an adiabatic fixed-bed reactor equipped with a solid acid catalyst for reaction, the catalyst used is composed of 8% molybdenum oxide, 5% nickel oxide, 4% phosphorus pentoxide, 8% ZSM-5 molecular sieve, and the rest is alumina carrier , the ZSM-5 molecular sieve has a silicon-aluminum ratio of 25, a grain size of 3 μm, a pore volume of 0.5ml / g, and a specific surface area of 168m 2 / g. The reaction effluent is cooled to 15°C by heat exchange, the gas phase is returned to the hydrogen sulfide feed, and the liquid phase is subjected to fractional distillation to obtain four products, namely, isopropyl mercaptan, n-propylene mercaptan, isopropyl sulfide and n-propyl sulfide. Wherein the single-pass conversion rate of propylene is 91.8%, the selectivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com