Method for producing biogas through semi-continuous dry anaerobic fermentation of cassava residues

A technology of dry anaerobic fermentation and cassava residues, which is applied in the field of semi-continuous dry anaerobic fermentation of cassava residues to produce biogas, can solve the problems of increased processing costs of cassava residues, increased process complexity, and increased operating costs, and achieve improved substrate conversion efficiency, less water consumption and less biogas slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The cassava residue used in this embodiment comes from the residue waste of a cassava starch factory in a certain city in Guangxi Zhuang Autonomous Region. The specific operation process is as follows:

[0023] (1) Take cassava slag, pass through a 60-mesh sieve after drying, and store in a refrigerator at 4°C for later use. The physical and chemical properties of cassava slag are shown in Table 1.

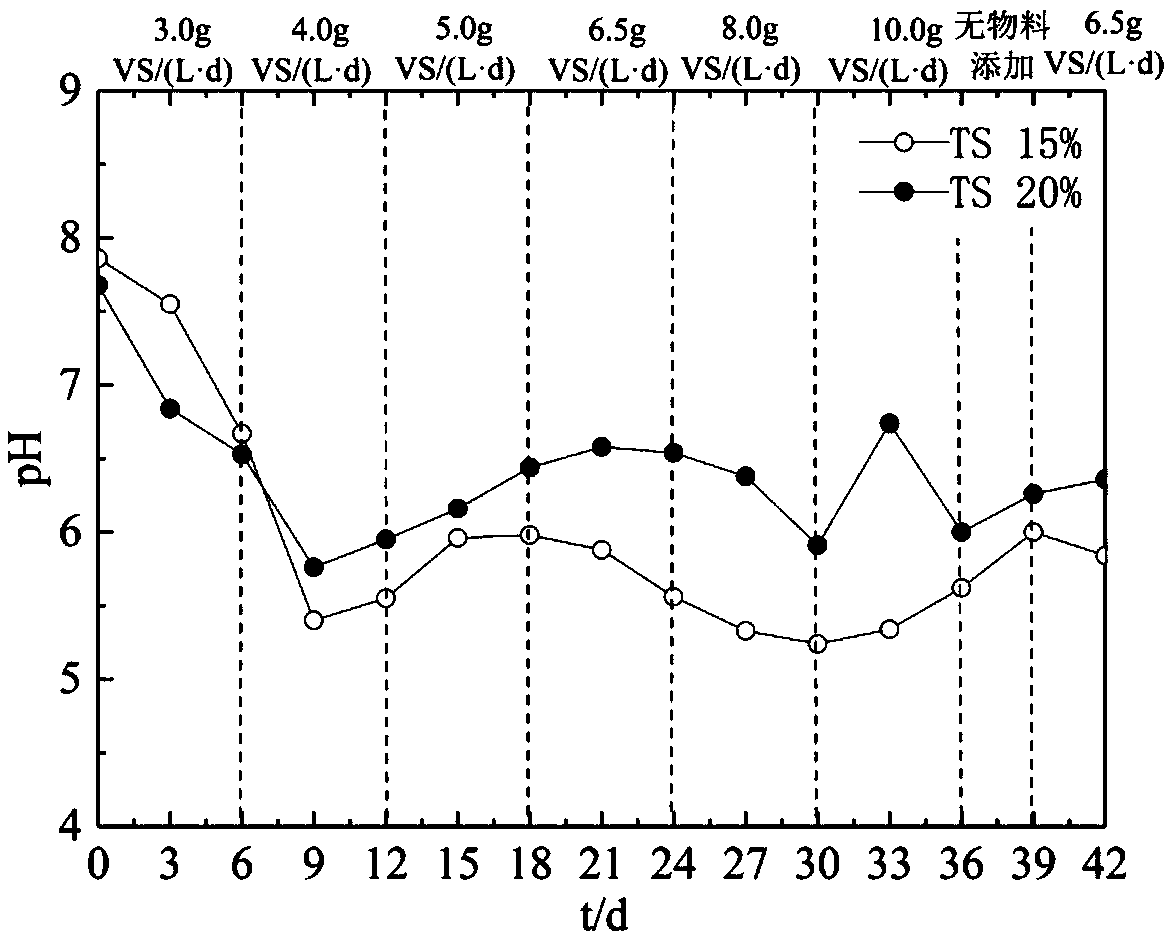

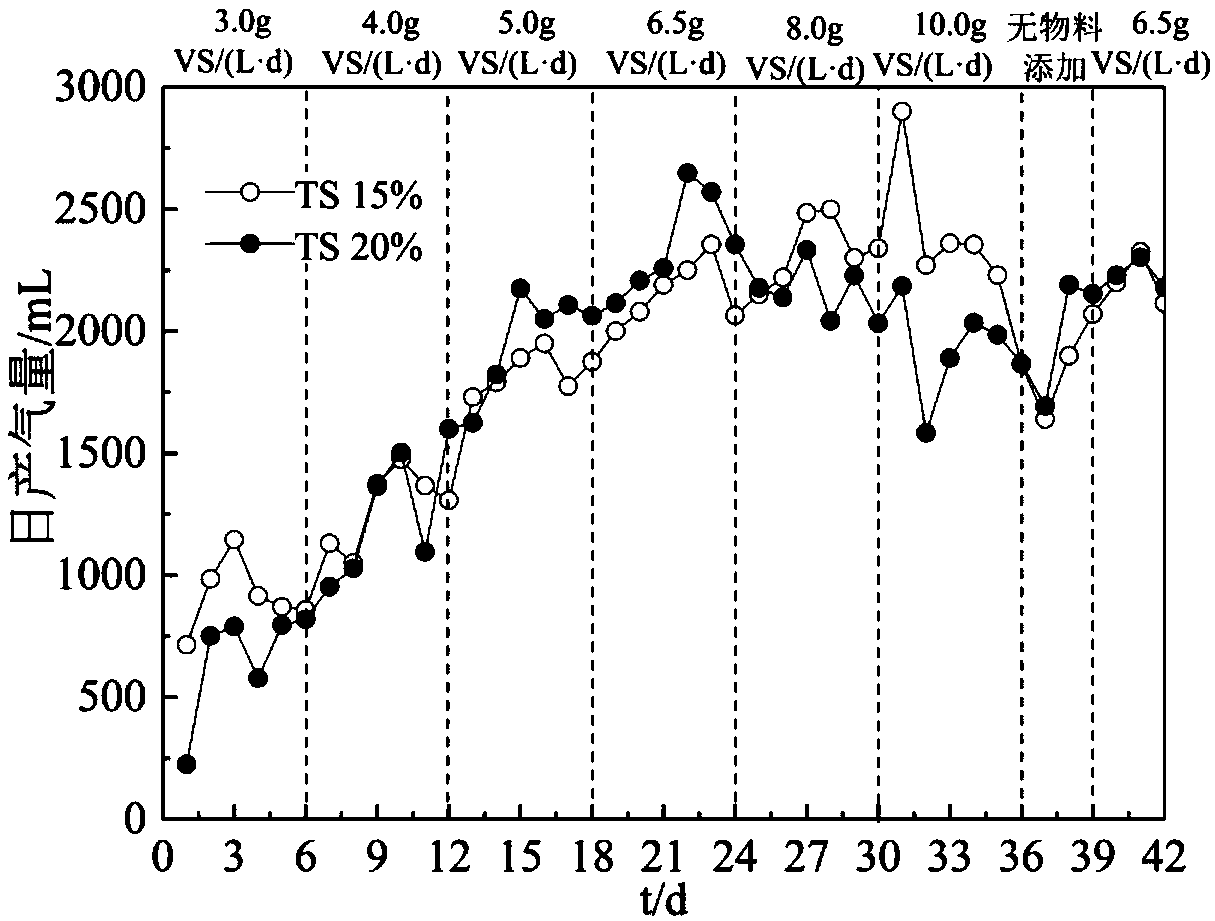

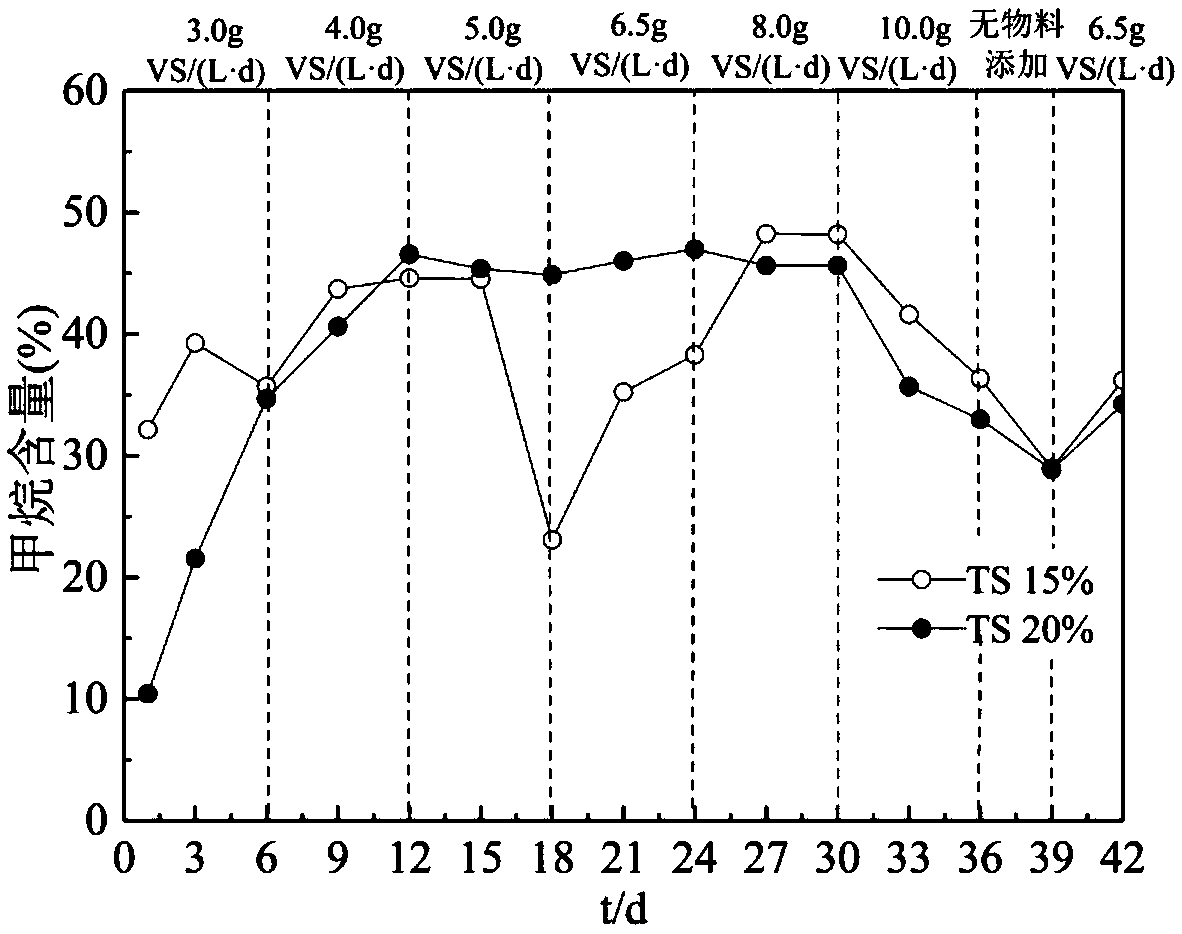

[0024] (2) Start with a load of 3.0gVS / (L·d), increase the load by 20% to 30% in each stage, the load starts to increase from 3.0gVS / (L·d), after 4.0, 5.0, 6.5, 8.0gVS / (L·d) until 10.0gVS / (L·d), every 6d is a load cycle.

[0025] (3) Mix the product of step (1) with biogas residue, add the mixture with a solid content (TS) of 15% into a 1L fermenter, and ferment anaerobically at 32-37°C for 42 days, adding Quantify the cassava residue, take out the same amount of mixture at the same time, and stir it irregularly. The daily addition amount is shown in Table 2.

[0026] T...

Embodiment 2

[0033] The cassava residue used in this embodiment comes from the residue waste of a cassava starch factory in a certain city in Guangxi Zhuang Autonomous Region. The specific operation process is as follows:

[0034](1) Take cassava residue, pass through a 60-mesh sieve after drying, and store in a refrigerator at 4°C for later use. The physical and chemical properties of cassava residue are shown in Table 1.

[0035] (2) Start with a load of 3.0gVS / (L·d), increase the load by 20% to 30% in each stage, the load starts to increase from 3.0gVS / (L·d), after 4.0, 5.0, 6.5, 8.0gVS / (L·d) until 10.0gVS / (L·d), every 6d is a load cycle.

[0036] (3) Mix the product of step (1) with biogas residue, add the mixture with a solid content rate of 20% into a 1L fermenter, perform anaerobic fermentation at 32-37°C for 42 days, and add quantitative cassava residue every day , and take out an equal amount of the mixture at the same time, and stir it irregularly. The daily addition amount is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com