Two-phase anaerobic tubular membrane bioreactor treatment method and device for organic wastewater

A technology of organic wastewater treatment and bioreactor, which is applied in anaerobic digestion treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the limitation of activity and conversion rate, the difficulty of preventing acidification of reactor, reactor and land occupation Large and other problems, to achieve the effect of less labor requirements, easy automatic control, and clean water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

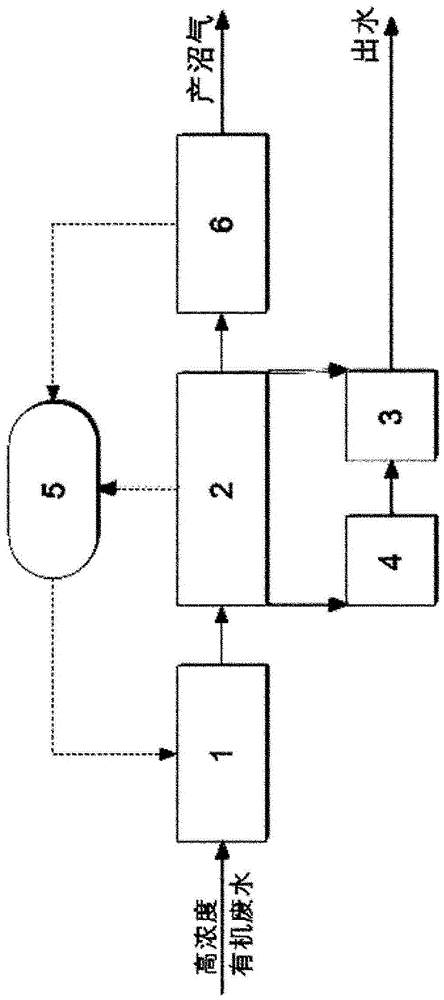

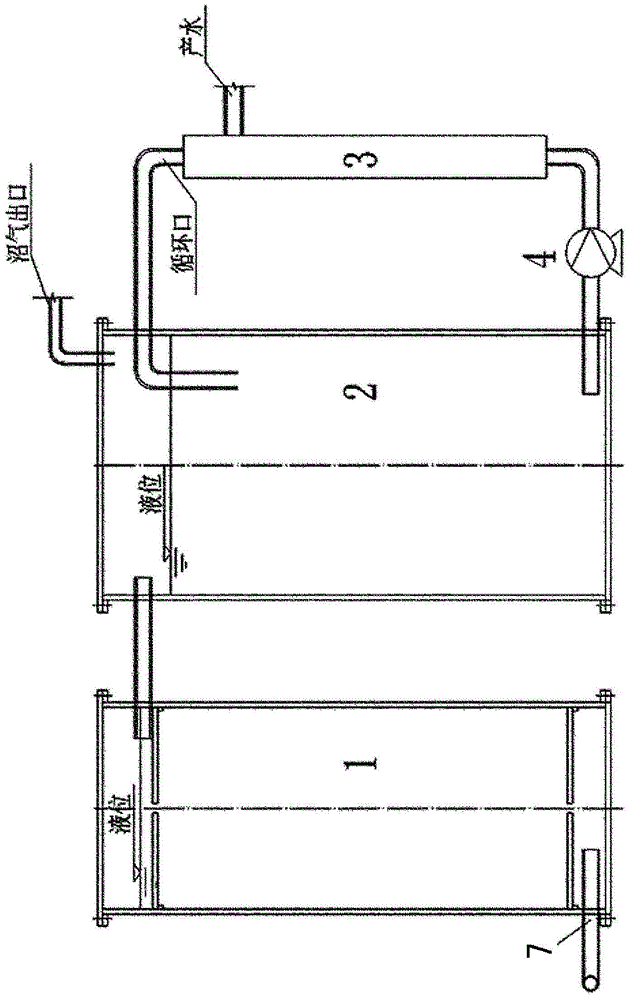

[0062] The membrane circulation reactor is composed of an up-flow composite acid production reactor 1, a completely mixed methane production reactor 2, a tubular membrane module 3, a circulation pump 4, a reactor control system 5 and a gas metering system 6. It is used for Treatment of waste water from agricultural and sideline food processing industry.

[0063] According to the organic load of the two phases (0.5-2.5kgCOD Cr / kgVSS*d) and residence time (0.5-7d), inoculate the anaerobic digested sludge into the upflow compound acidogenic reactor 1 and the complete mixed methanogenic reactor 2, respectively, and then gradually increase the sewage dosage. The inoculum sludge can be derived from the anaerobic digestion process of surplus sludge or other agricultural and sideline food processing wastewater.

[0064] After inoculation, the wastewater from the agricultural and sideline food processing industry pumped in from the water inlet is transported to the up-flow composite ...

Embodiment 2

[0068] The internal membrane circulation reactor is composed of an upflow composite acid production reactor 1, a completely mixed methanation reactor 2, a tubular membrane module 3 and a circulation pump 4, and is used for treating urban sewage.

[0069] According to the organic load of the two phases (0.5-2.5kgCOD Cr / kgVSS*d) and residence time (0.5-7d), inoculate the anaerobic digested sludge into the upflow compound acidogenic reactor 1 and the complete mixed methanogenic reactor 2, respectively, and then gradually increase the sewage dosage. The seed sludge may originate from an anaerobic digestion process of surplus sludge.

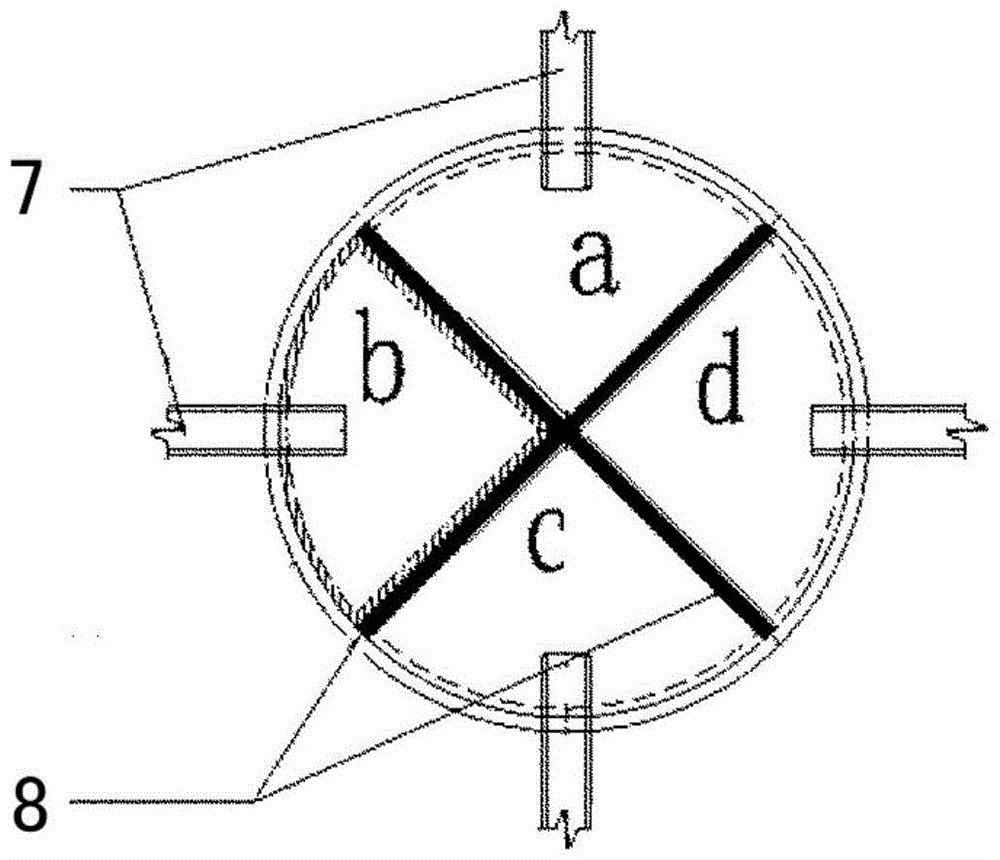

[0070] After inoculation, the urban sewage pumped from the water inlet after the sand settling and the membrane grid is transported to the upflow compound acid production reactor, and then passes through the four reaction chambers a, b, c, and d successively, and enters the complete Mixed-type methanogenic reactor; the methane-phase mixed liquid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com