Method for making low-alcohol or alcohol-less raw juice fermented alcohol drink by low-temperature two-tower rectification method

A double-tower rectification and alcohol fermentation technology, applied in the preparation of alcoholic beverages, food science and other directions, can solve the problems of unsatisfactory proportion of aromatic components and no practical and effective solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

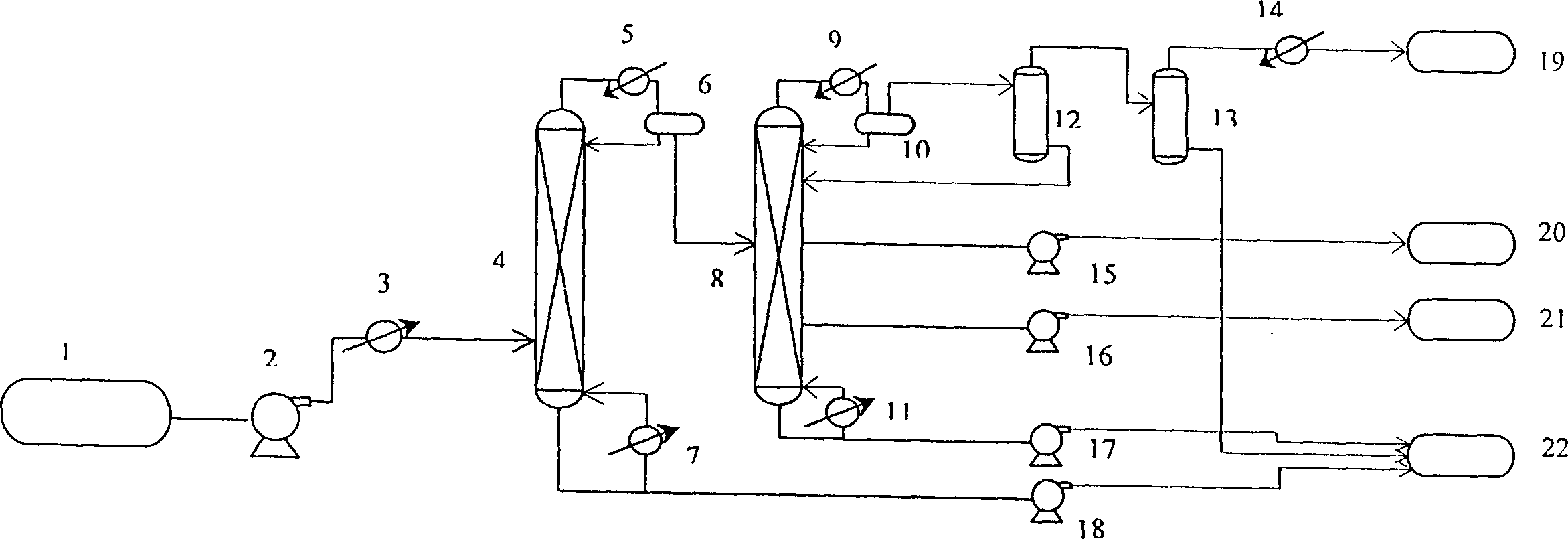

[0032] Embodiment 1: Two low-temperature separation and rectification towers are adopted, the tower diameters are 200mm and 100mm respectively, and the theoretical plate height is 60 pieces. The SINOPAK-500 wire mesh packing produced by Jiangsu Huaji Tower Industry is used, and the reboiler at the bottom of the tower is uniform. Thin-film evaporator (NB series-12m produced by Hengyang Jinshan Traditional Chinese Medicine Equipment Manufacturing Co., Ltd.) 2 Thin film evaporator with heating area). according to figure 1 According to the process, take dry red wine (Changyu dry red, Yantai Changyu Company, the ethanol concentration of the original wine is about 15.77% (w / w)) from container 1 with a feed rate of 10Kg / h and heat it to 35°C and enter the first rectification tower 4. The operating pressure at the top of the tower is 6665Pa, and the reflux ratio is 20. The mixture of water, ethanol and aromatics produced at the top of the tower is about 2Kg / h, which enters the secon...

Embodiment 2

[0033] Example 2: Take dry red wine from container 1 and heat it to 15°C to enter the first rectification tower 4. The operating pressure at the top of the tower is 2667 Pa, and the reflux ratio is 15. The mixture of water, ethanol and aroma produced at the top of the tower enters the second rectification tower 8 at 15°C. The operating pressure at the top of the second rectification tower is 2667 Pa, and the reflux ratio is 25. The temperature of the first stage partial condenser 9 on the top of the tower is about 17°C, the temperature of the second stage partial condenser 12 is about 5°C, the temperature of the third stage partial condenser 13 is about -13°C, and the temperature of the total condenser 14 is about -19°C. All the other test conditions are exactly the same as in Example 1. The result is consistent with Example 1.

Embodiment 3

[0034] Example 3: Take dry red wine from container 1 and heat it to 50°C to enter the first rectification tower 4. The operating pressure at the top of the tower is 13333 Pa, and the reflux ratio is 25. The mixture of water, ethanol and aroma produced at the top of the tower enters the second rectification tower 8 at 50°C. The operating pressure at the top of the second rectification tower is 13333 Pa, and the reflux ratio is 35. The temperature of the first stage partial condenser 9 on the top of the tower is about 16°C, the temperature of the second stage partial condenser 12 is about 4°C, the temperature of the third stage partial condenser 13 is about -12°C, and the temperature of the total condenser 14 is about -19°C. All the other test conditions are exactly the same as in Example 1. The result is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com