Method for preparing Guerbet alcohol

A technology for Guerbet alcohols and primary alcohols, applied in the field of preparing Guerbet alcohols, can solve the problems of decreased yield of Guerbet alcohols, increased energy consumption and manpower consumption, unsuitable for less than 6 carbons, etc. , to achieve the effects of shortened response time, reduced energy consumption and labor consumption, and great prospects for popularization and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

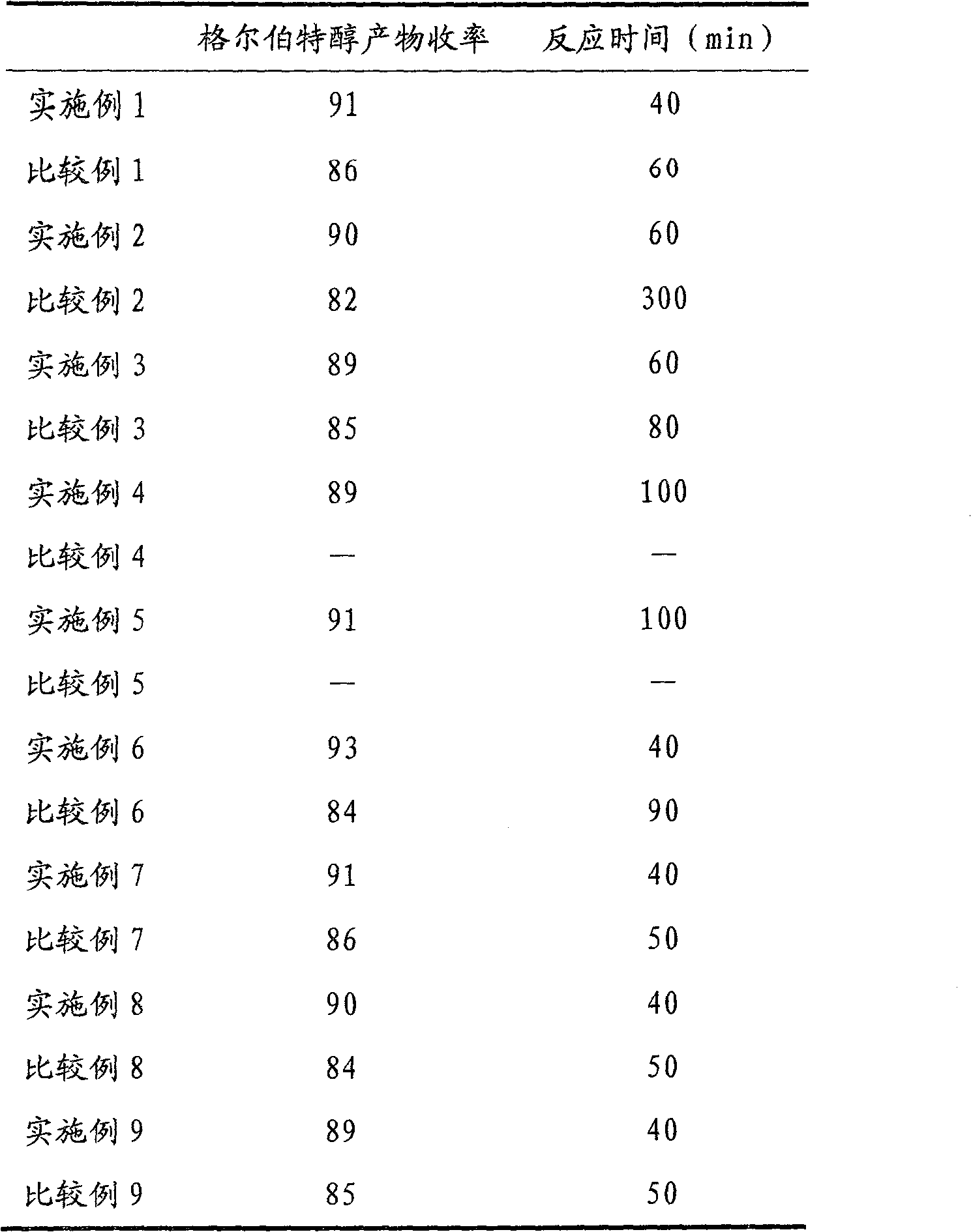

Embodiment 1

[0010] Example 1: After mixing 160g lauryl alcohol, 2g KOH and 0.6g nickel powder, put into a reactor with a water separator and stir and feed nitrogen to remove the air in the reactor, then heat up under the protection of 0.4MPa nitrogen Condensation reaction is carried out at 250°C. During the reaction process, the water generated by the reaction is continuously separated from the reaction system through the water separator. After the reaction is carried out for 40 minutes, the reaction is terminated when no water is detected, and the reactant is filtered to remove the catalyst when it is cooled to room temperature. , the filtrate was distilled under reduced pressure to obtain C 24 Guerbet alcohol 145.6 grams, the reaction yield is 91%.

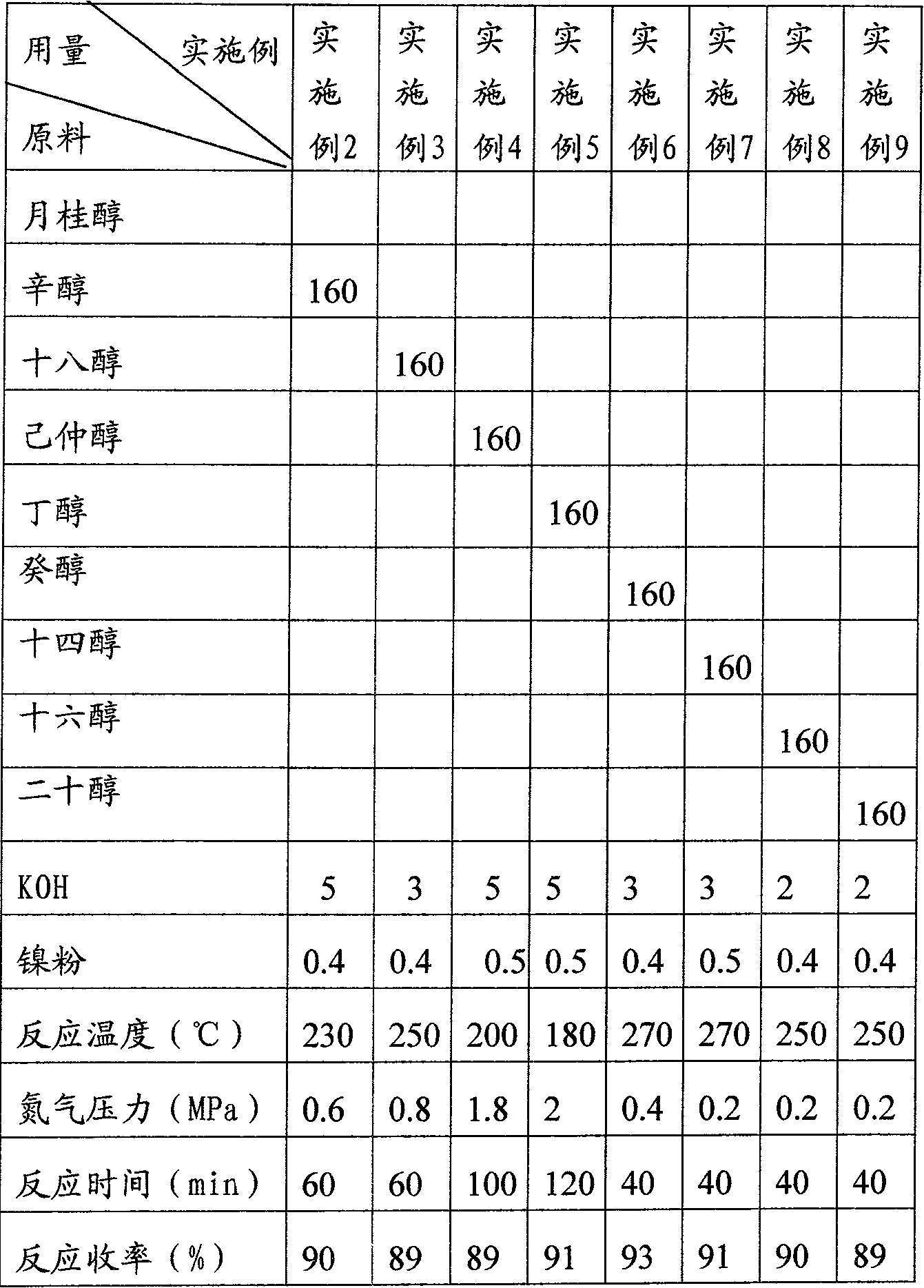

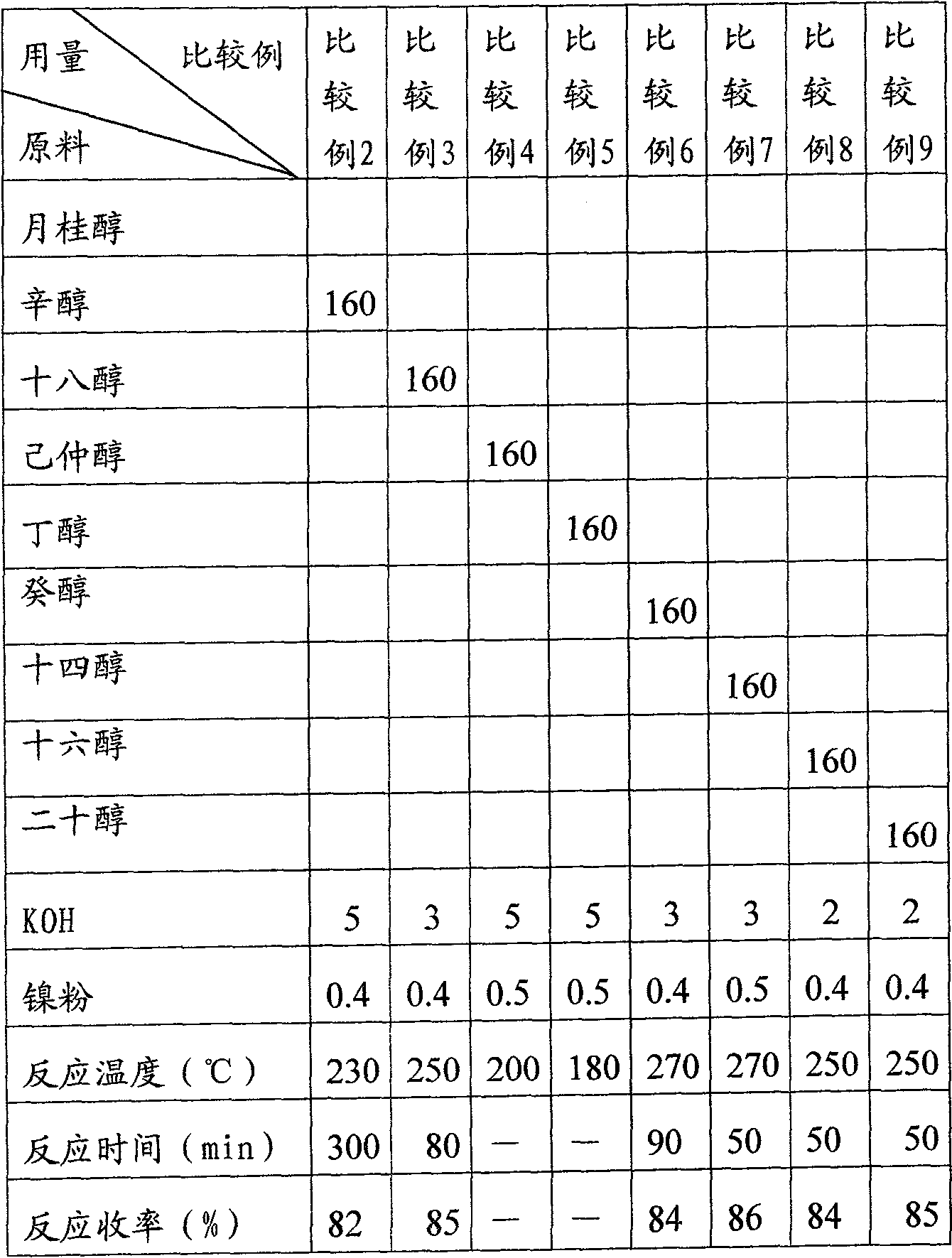

[0011] The operation process of other embodiments is the same as that of Embodiment 1, and the differences are shown in Table 1 below. Embodiment 4~Example 9 products are respectively: 1,3-dimethyl-2-propyl heptanol, C 8 Guerbet Alcohol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com