Method and device for producing biomass absolute ethyl alcohol

An anhydrous ethanol, production method technology, applied in the fields of biofuels, chemical instruments and methods, preparation of organic compounds, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

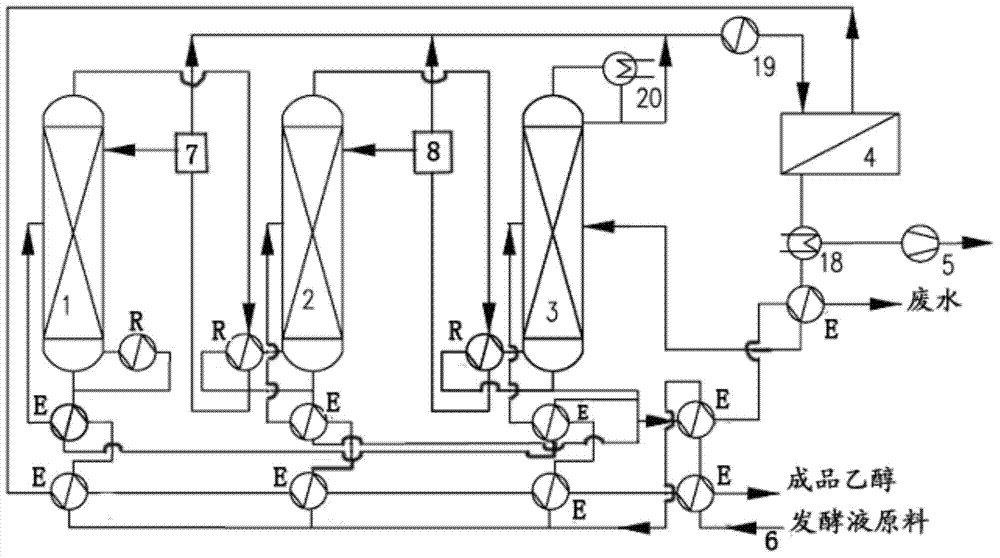

[0068] like figure 1 , The equipment used in the separation technology in the absolute ethanol production process described in the embodiment of the present invention includes: a pressurized rectification tower 1, an atmospheric rectification tower 2, a vacuum rectification tower 3, a pervaporation membrane 4, a vacuum pump 5 , reboiler; heat exchanger; permeate condenser 18; heater 19; tower top condenser 20, all equipments are connected by pipelines and valves.

[0069] 10900kg / h 40°C raw material solution containing 11.4wt% ethanol from the fermentation section is input into the rectification-pervaporation system through the pipeline. The absolute pressure at the top of the pressurized distillation column 1 is 0.42MPa, the temperature at the top of the column is 119°C, and the temperature at the bottom of the column is 146°C. The heat of the reboiler at the bottom of the column is provided by primary steam, and the reflux ratio is 0.58; The absolute pressure at the top of...

Embodiment 2

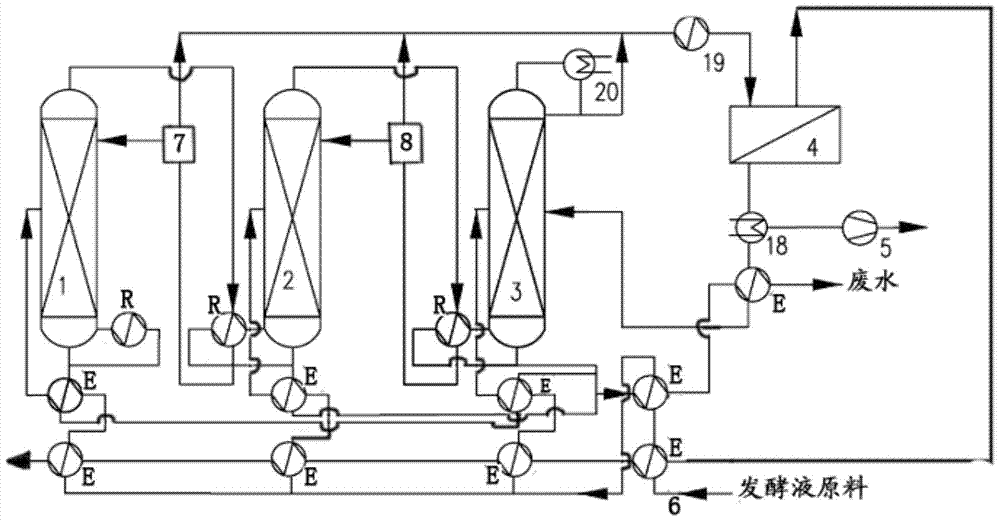

[0075] devices such as figure 2 As shown, the difference from Example 1 is that the heat exchange sequence of the dehydrated ethanol of the pervaporation membrane 4 has changed, and it first carries out the first-stage heat exchange with the total feed liquid of the fermentation broth raw material, and then, the feed liquid and The mixed liquid in the bottom of the rectification tower is subjected to second-stage heat exchange, and then the dehydrated ethanol is sequentially exchanged with the materials that enter the vacuum, normal pressure, and pressurized rectification towers separately to obtain 99.7% ethanol per ton. The amount of steam is 1.40-1.45 tons.

[0076]

Embodiment 3

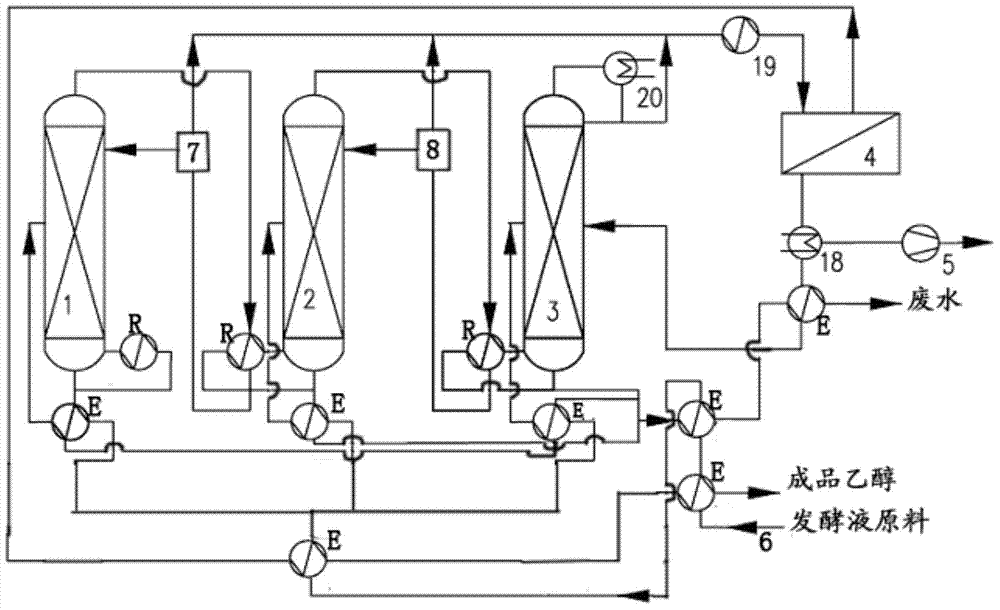

[0078] like image 3 As shown, the difference from Example 1 is that the heat exchange mode of the dehydrated ethanol of the pervaporation membrane 4 has changed, and it first carries out three-stage heat exchange with the fermented liquid that has undergone the two-stage heat exchange. It is not as in Example 1 that the raw material liquids entering the three rectification towers are sequentially heat-exchanged, but the total fermented liquid from the heat exchanger is directly heat-exchanged, and then split to the three distillation towers. A rectification tower, and the feed liquid after the split is then subjected to four-stage heat exchange with the bottom liquid of the rectification tower, and the amount of steam required per ton to obtain 99.7% ethanol is 1.4 to 1.5 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com