Second esterification reactor in continuous production device of poly (trimethylene terephthalate)

A technology of polyethylene terephthalate and propylene glycol, which is applied in the field of the second esterification reactor, can solve the problems of reducing production costs, complicated process flow, unfavorable production management, etc., and achieves the improvement of product quality, guaranteed reaction time, and guaranteed sequence flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

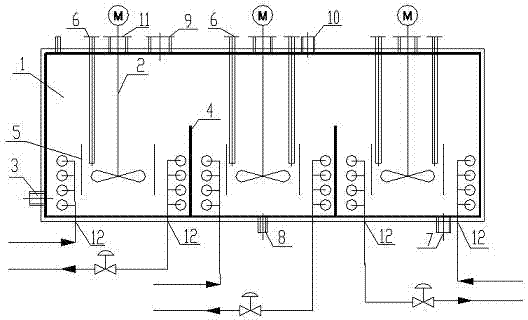

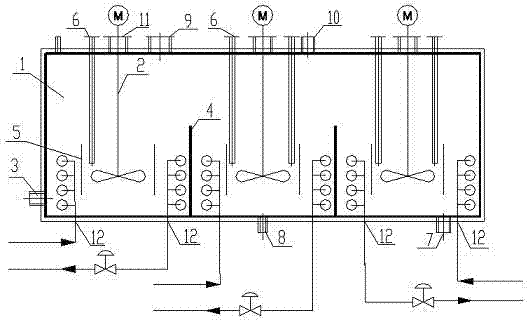

[0019] Such as figure 1 As shown, the present invention provides a second esterification reactor in a continuous production device for poly(trimethylene terephthalate) 1,3-trimethylene, comprising a reactor tank body 1, and the reactor tank body is a horizontal tank body , which is provided with one or more partitions 4, the partition divides the inner space of the reactor body into at least two chambers, the upper edge of the partition and the upper part of the reactor body There is a space between the inner walls. The length of each of the chambers can be set to be equal or unequal according to specific process requirements and actual conditions. For example, the position of the partition can be set according to the difference in the required residence time of the esterified product in each of the chambers, so that the The chambers are set with different lengths to control the residence time of the materials in each chamber so as to provide greater controllability for addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com