CMOS MEMS capacitance-type humidity sensor and preparation method thereof

A humidity sensor and capacitive technology, which is applied in the field of CMOS MEMS capacitive humidity sensor and its preparation, and semiconductor chips, can solve the problems of easy cracking and difficult guarantee of mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

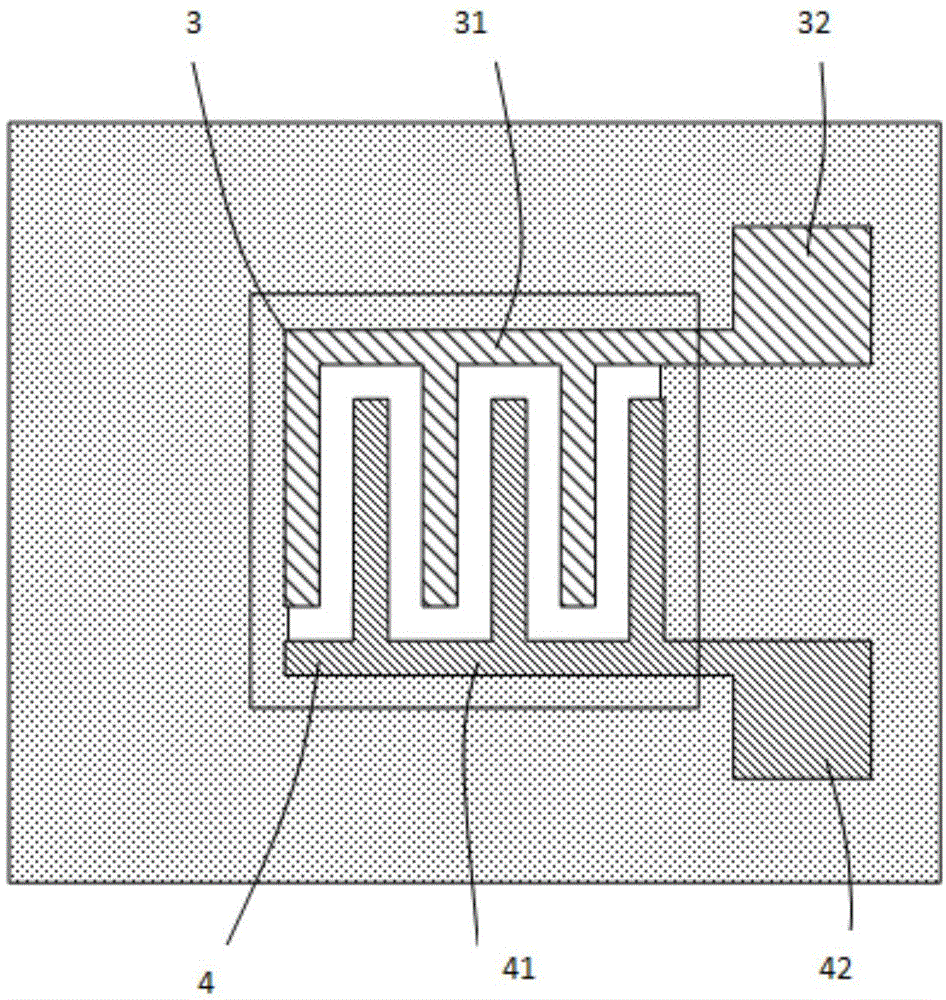

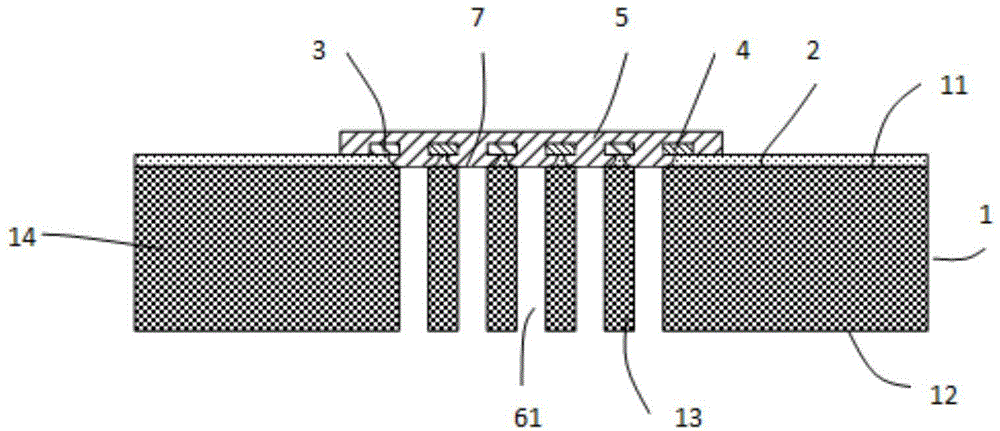

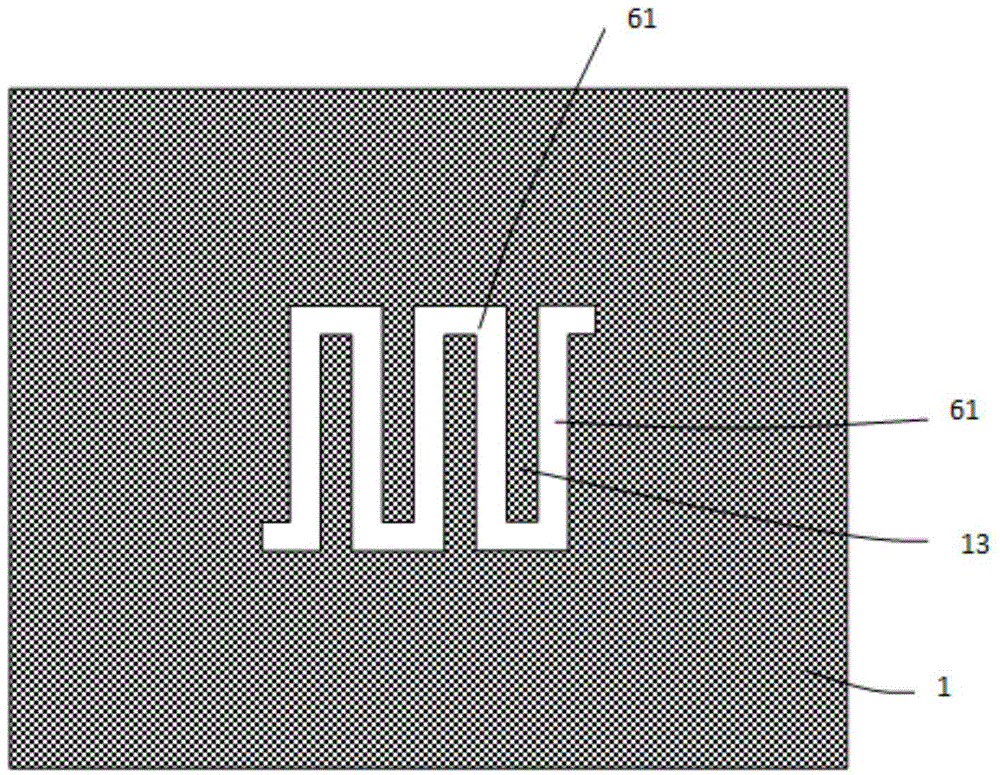

[0029] see Figure 1 to Figure 3 The CMOS MEMS capacitive humidity sensor described in a preferred embodiment of the present invention (hereinafter referred to as the humidity sensor) comprises a substrate 1 with a front side 11 and a back side 12, an oxide layer deposited on the front side 11 of the substrate 1 2. The first capacitive electrode 3 and the second capacitive electrode 4 arranged on the oxide layer 2, the humidity sensitive medium layer 5 filled between the oxide layer 2, the first capacitive electrode 3 and the second capacitive electrode 4 ( figure 1 (shown only in frame), several air sub-channels 61 extending from the back side 12 of the substrate 1 towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com