Multifunctional oil-contained waste water treatment device

A technology for treating device and oily sewage, which is used in flocculation/sedimentation water/sewage treatment, grease/oily substance/float removal device, liquid separation, etc. Formation and settling, ensuring reaction time, prolonging the effect of flowing through the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

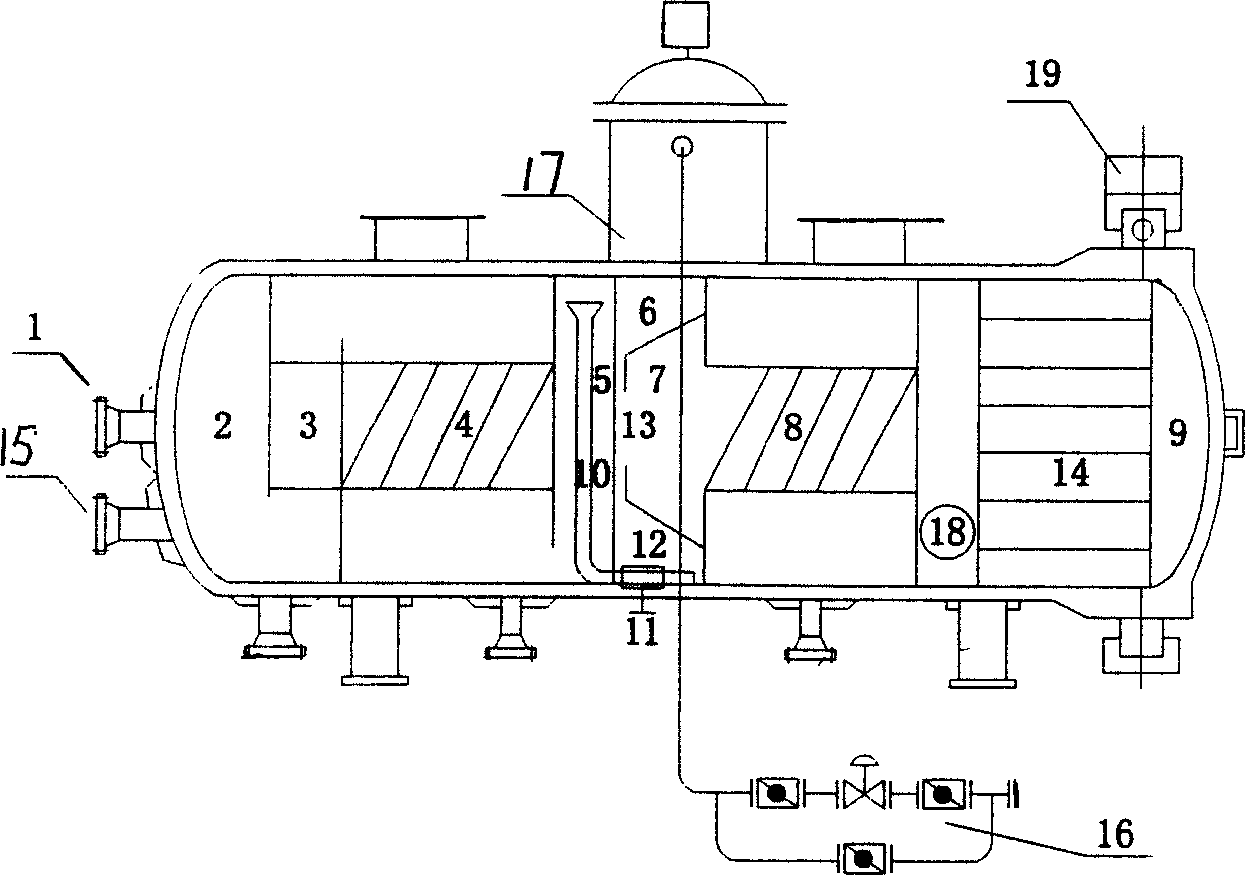

[0012] Multi-functional oily sewage treatment device, one end of the horizontal closed cylinder is an elliptical head, on which are installed a water inlet pipe 1 and a backwash water pipe 15, and the other end is a quick-opening flange 19 that is hydraulically controlled to open and close. An oil bag 17 is provided, and the oil bag 17 is controlled by an automatic oil discharge device 16 .

[0013] The cylinder body is designed in the order of processing procedures as a buffer chamber 2 connected to the water inlet pipe 1, a coarse granulation chamber 3, a first-stage inclined plate / pipe degreasing chamber 4, a water collection chamber 5, a first-stage flocculation reaction chamber 6, The second-stage flocculation reaction chamber 7, the second-stage inclined plate / pipe degreasing and settling chamber 8, and the filter chamber 9, each chamber is connected with water in turn, the second-stage reaction chamber 7 is conical, and its periphery is the first-stage reaction chamber 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com