Sludge agitator tank

A technology for stirring tanks and sludge, applied in the direction of dehydration/drying/thickened sludge treatment, etc., to achieve the effect of low operating cost, simple structure, and extended flow lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

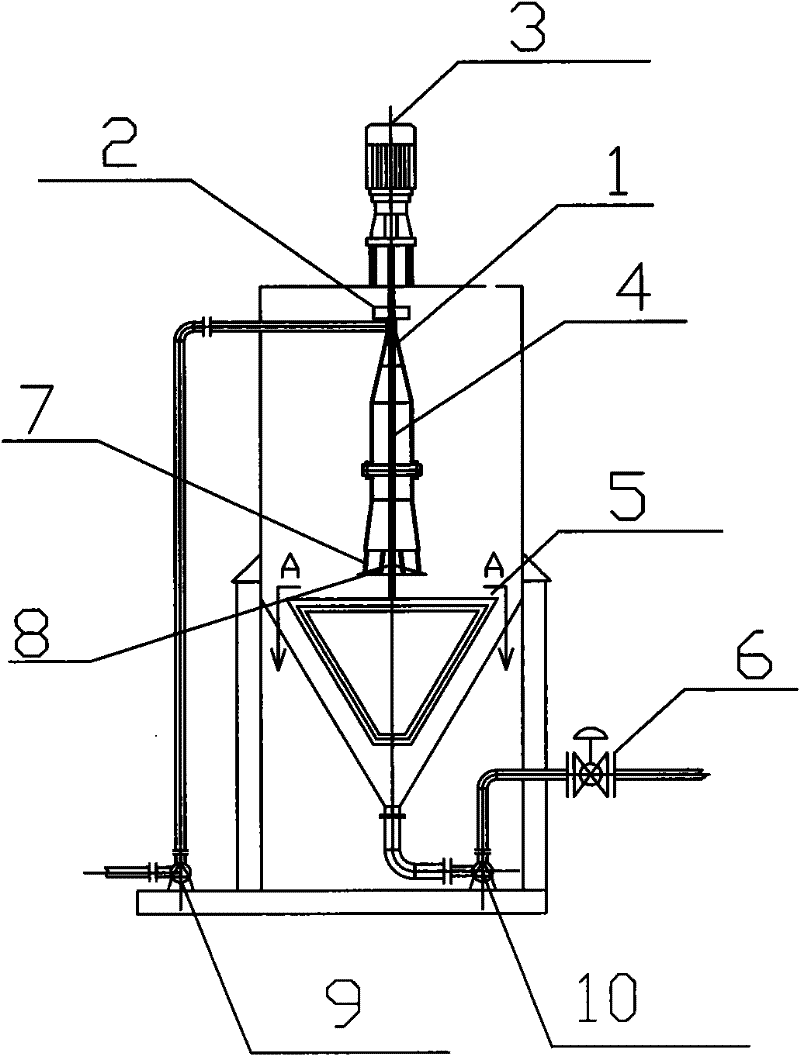

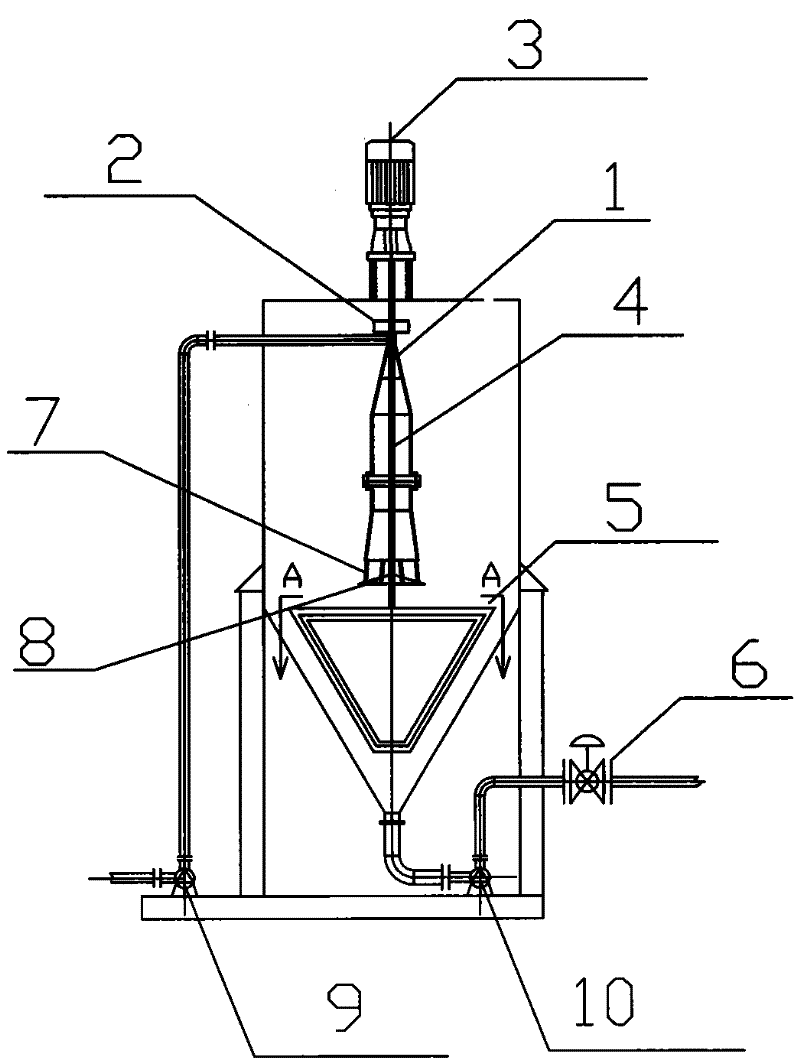

[0015] Such as figure 1 , The sludge mixing tank is mainly composed of a tank body, a central reactor 1, an oil collecting ring 2, a motor 3, and a stirring paddle 5, wherein:

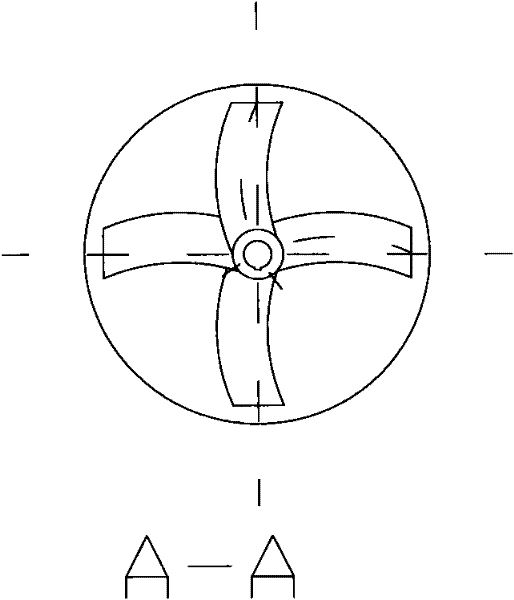

[0016] The motor 3 is installed on the top of the tank, and its output shaft extends to the bottom of the tank. A fixed central reactor 1 is coaxially installed in the tank. The central reactor 1 is a thin-walled and hollow stepped truncated cone. The bottom end is connected to the water retaining plate 8 through several vertical grids 7 . The mouth of the sludge conveying pipe is inserted into the upper part of the central reactor 1 in a horizontal and oblique direction. The oil collecting ring 2 is arranged on the top of the central reactor and communicates with the reaction chamber 4 inside the central reactor. The oil collecting ring 2 is connected with an oil collecting pipe to collect The light oil is exported to the sludge mixing tank; the stirring paddle 5 is installed at the bottom of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com