Synchronous control system and method for heavy-duty locomotive

A technology for synchronous control and heavy-duty locomotives, which is applied in locomotives and other directions to ensure response time, facilitate promotion, and improve safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

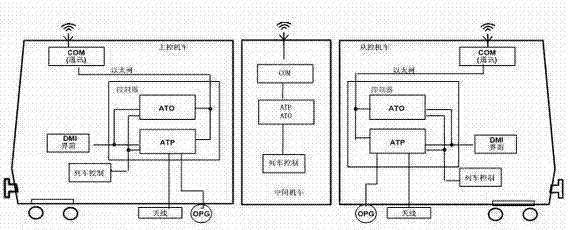

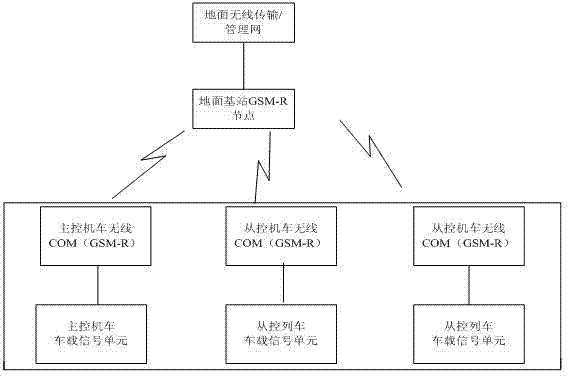

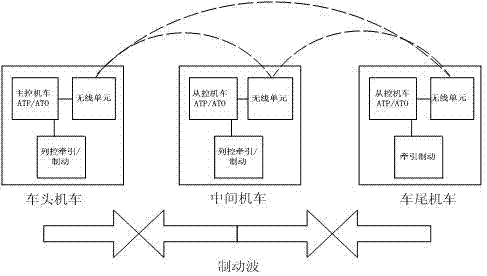

[0029] Such as figure 1 as shown, The synchronous control system of heavy-duty locomotive signal There are master locomotives, intermediate locomotives, and slave locomotives, and ATP / ATO equipment is installed in the master locomotives, intermediate locomotives, and slave locomotives.

[0030] The ATP / ATO equipment installed on each locomotive is exactly the same, the purpose is to facilitate marshalling.

[0031] Each set of ATP / ATO equipment Including: ATP sub-box, ATO sub-box, wireless COM, DMI interface, vehicle control;

[0032] ATP plug-in box: 3 out of 2 security computers are used, and the 3 CPUs operate independently. When the calculation results of 2 or 3 CPUs are the same, the control logic is output. The ATP is responsible for the train's safety functions, including command generation, transmission, and application of emergency braking.

[0033] ATO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com