Automatic operation system of drilling string

A technology for operating system and drilling pipe string, applied in drill pipe, drilling equipment, drill pipe, etc., can solve the problems of reducing labor intensity, high labor intensity, low efficiency, etc., and achieve the effect of improving the degree of automation and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

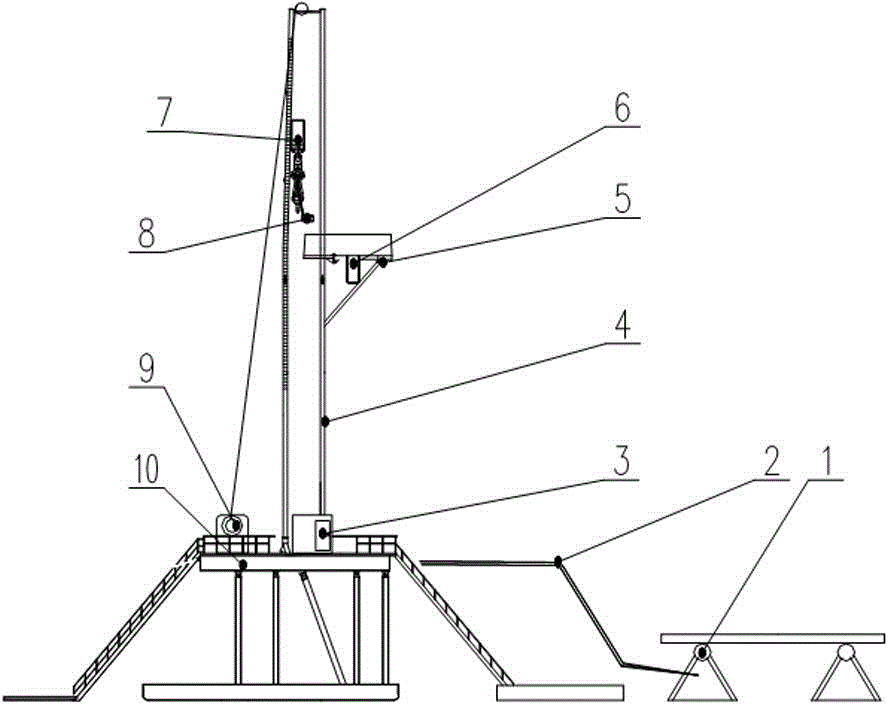

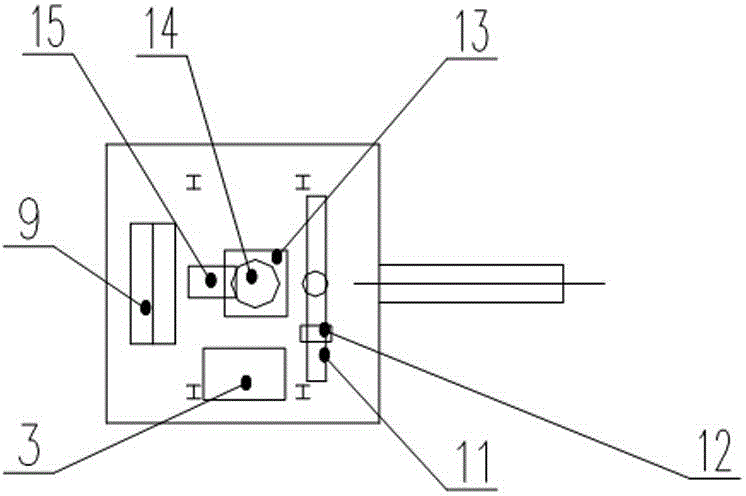

[0021] An automatic operating system for drilling pipe strings, including an automatic catwalk machine 2, a drill floor manipulator 12, a power slip 14, an iron driller 15, a power elevator 8, a second-floor pipe-discharging manipulator 6, a top drive 7, and a drawworks 9 , Driller integrated control system 3 and drill floor 10, derrick 4, two-story platform 5, turntable 13, guide rail 11. Among them: the automatic catwalk machine 2 is installed directly in front of the drill floor 10, and the drill floor manipulator 12 is installed on the table surface of the drill floor 10 close to the automatic catwalk machine 2 through the guide rail 11; the power slip 14 is installed on the hub of the turntable 13 Inside, the iron driller 15 is installed on the platform of the drill floor 10 between the winch 9 and the turntable 13; the power elevator 8 is installed on the lifting ring of the top drive 7, and the second-floor pipe-discharging manipulator 6 is installed under the second-flo...

Embodiment 2

[0023] An automatic operating system for drilling strings is mainly composed of an automatic catwalk machine 2, a drill floor manipulator 12, a power slip 14, an iron driller 15, a power elevator 8, a pipe row manipulator 6 on a second-floor platform, a top drive 7, and a drawworks 9 , driller integrated control system 3, etc., the automatic catwalk machine 2 is installed in front of the drill floor 10, the drill floor manipulator 12 is installed on the surface of the drill floor 10 through the guide rail 11, and the power slip 14 is installed on the core of the turntable 13 Inside, the iron driller 15 is installed on the surface of the drill floor 10 between the drawworks 9 and the turntable 13, the power elevator 8 is installed on the lifting ring of the top drive 7, and the second-floor pipe-discharging manipulator 6 is installed under the second-floor platform 5 , the top drive 7 is installed under the swimming block in the derrick 4 of the drilling rig, the drawworks 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com