Hollow glass argon intervention assembly, device and method

A glass and hollow technology, applied in the field of hollow glass argon gas intervention components, can solve the problems of low production efficiency, unstable quality, aluminum alloy frame and sealant damage, and achieve the effect of avoiding blockage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

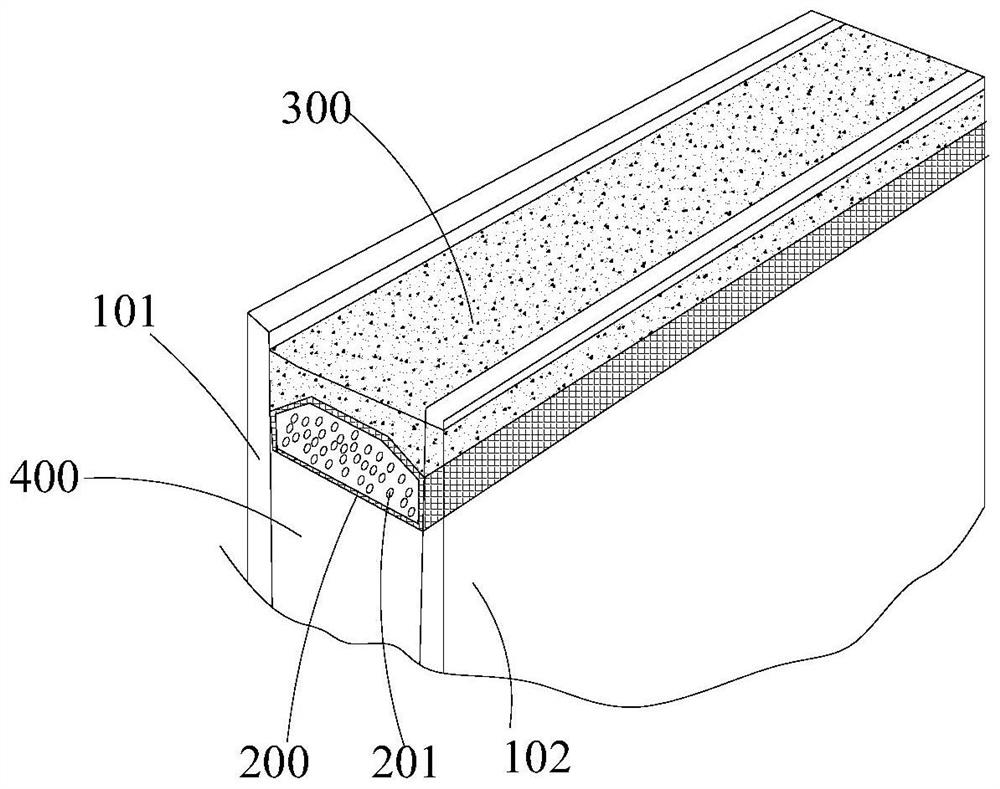

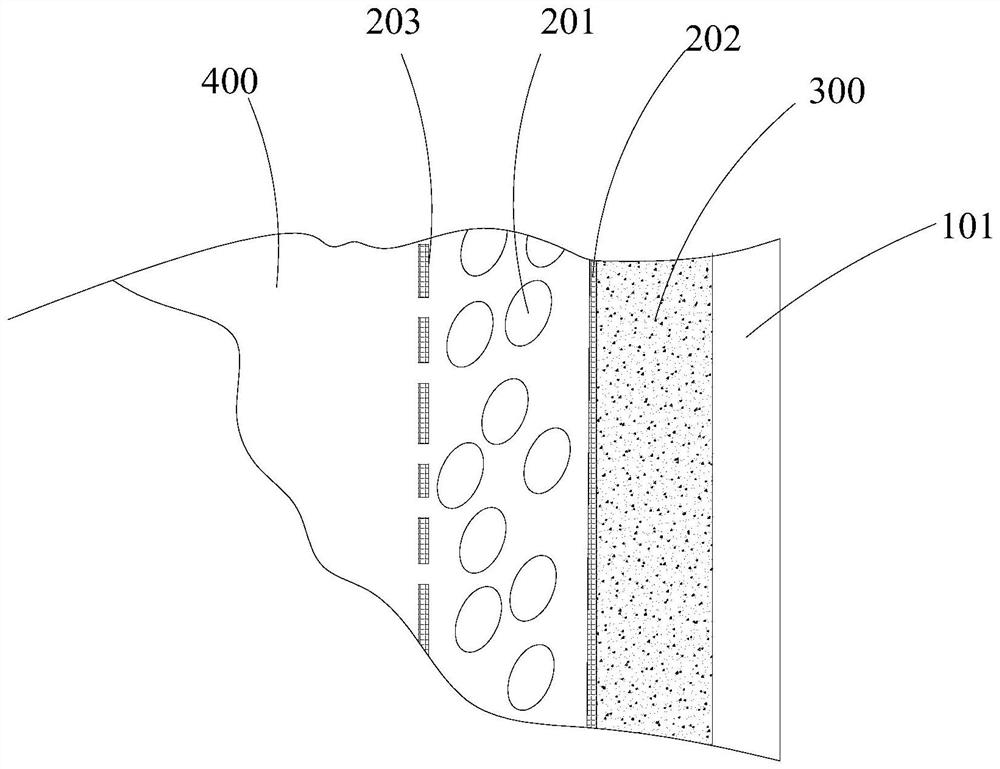

[0064] An insulating glass argon intervening component, used for insulating glass, the structure of the insulating glass is as follows figure 1 As shown, the first glass sheet 101 and the second glass sheet 102 clamp the aluminum alloy support frame 200 , and are bonded on the outside of the support frame 200 by a sealant layer 300 . Wherein the supporting frame 200 of aluminum alloy is filled with molecular sieve 201 for drying. figure 2 It is a partial structure, from the outside to the inside of the insulating glass, that is, from figure 2 From the right side to the left side, there are the edge of the first glass sheet 101 , the sealant layer 300 , the frame outer layer 202 , the molecular sieve 201 , the frame inner layer 203 and the filling space 400 .

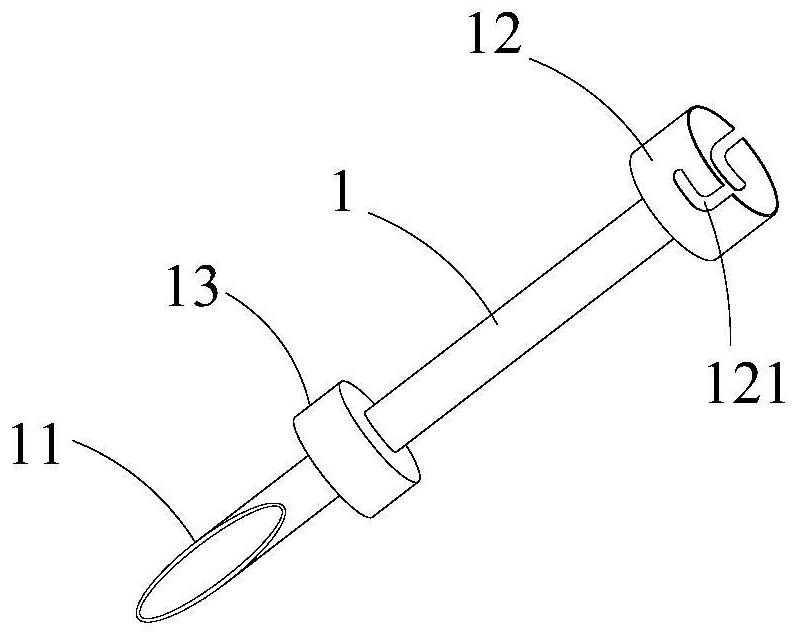

[0065] The hollow glass argon gas intervention assembly includes a first needle tube 1 and a second needle bar 2; the first needle tube 1 is as image 3 and Figure 7 As shown, the first needle tube 1 is a tubular b...

Embodiment 2

[0085] The difference between this embodiment and embodiment 1 is that, as Figure 15 As shown, the first fixing piece 12 is a tubular piece with external threads; the second fixing piece 22 is combined with the first fixing piece 12 through the fixing nut 5; in the third needle tube 3, the third stopper 31 is directly used as the first Three fixing parts 32, the third fixing part 32 (the third limiting block 31) is combined with the first fixing part 12 through the fixing nut 5; the fourth fixing part 42 is combined with the first fixing part 12 through the fixing nut 5; wherein the second The setting of the fixing piece 22, the third limiting block 31 (the third fixing piece) and the fourth fixing piece 42 is as follows: Figure 16 , Figure 17 and Figure 18 shown. The cross-sectional structure of fixed nut 5 is as Figure 19 As shown, the fixing nut 5 has an internal thread matching the external thread of the first fixing member 12 . The rear end of the fixing nut 5 h...

Embodiment 3

[0089] An argon interventional device for hollow glass, including a perforating device, an air supply device, and a glue injection device; the perforating device can be combined with the combination of the first needle tube and the second needle bar, and penetrate the combination into the sealant layer and the frame The outer layer, such that the front end of the composite is within the support frame. The gas supply device includes an argon gas storage tank, a gas supply pipeline and a control system. The argon storage tank is connected to the third needle tube through the gas supply pipeline, and the control system is arranged on the gas supply pipeline, and is used for controlling the gas filling switch and the flow rate of the argon gas. The glue injection device is connected with the fourth needle tube, and is used for supplying glue to the fourth needle tube.

[0090] The hollow glass argon gas intervention device includes several hollow glass argon gas intervention comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com