Methods for detecting actual capacity, residual capacity, standby time and health condition of battery

A technology of battery remaining capacity and detection method, applied in the direction of measuring electrical variables, measuring current/voltage, measuring electricity, etc., can solve the problem of difficulty in quantifying the degree of decline, and cannot reflect the health status of the battery, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] During multiple discharges of the battery, the attenuation degree of the battery can be reflected by recording and comparing the amount of electricity released when each discharge is placed at a certain set voltage. In this paper, the recorded percentage value of the current discharge capacity of the battery to the last discharge capacity is called the battery decay ratio.

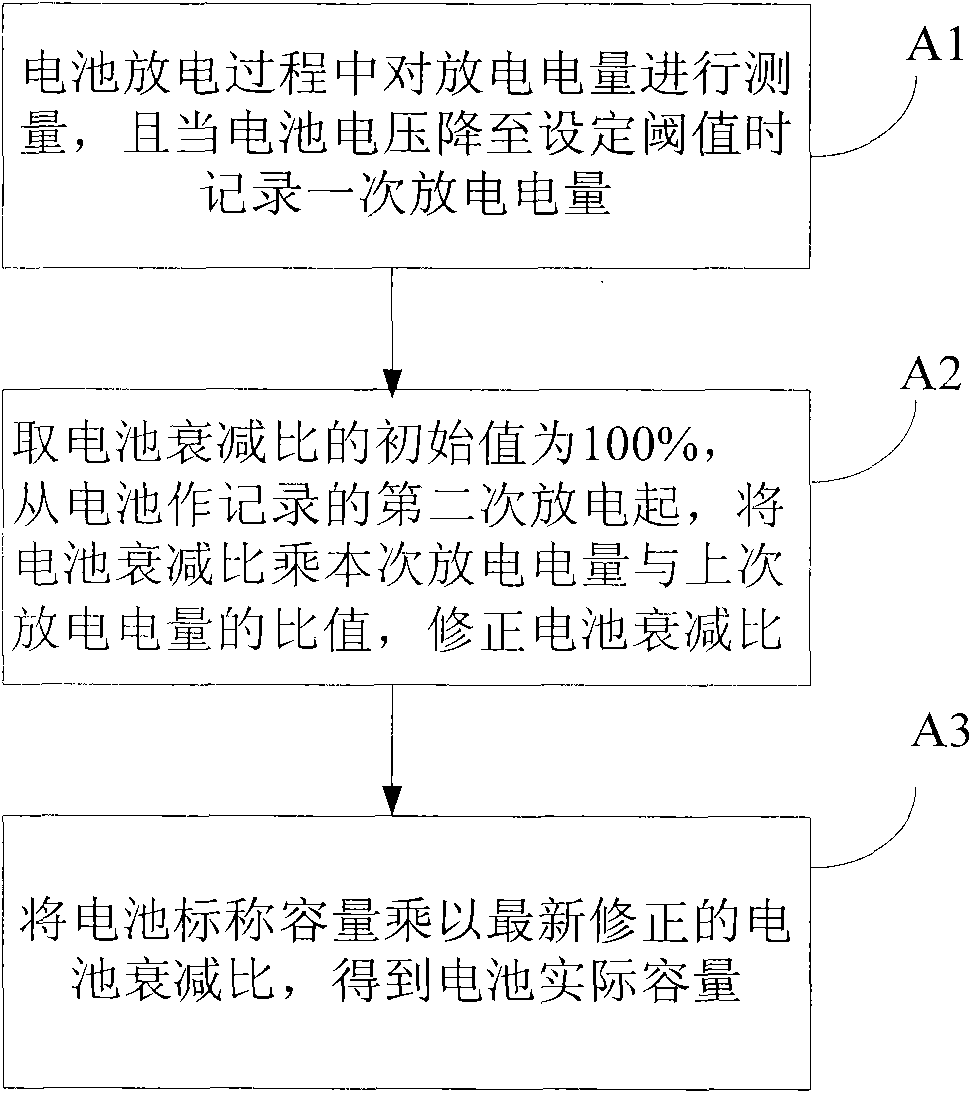

[0047] Please refer to figure 1 , the battery actual capacity detection method of the present invention comprises the following steps:

[0048] Step A1. Measure the discharge power during the battery discharge process, and record the discharge power once when the battery voltage drops to a set threshold;

[0049] Step A2. Take the initial value of the battery attenuation ratio as 100%. From the second discharge recorded by the battery, after discharge, multiply the battery attenuation ratio by the ratio of the current discharge power to the last discharge power to correct the battery attenuation ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com