Method for lithium pre-embedment of negative electrode of lithium ion capacitor

A capacitor and lithium-ion technology, applied in the field of lithium-ion capacitors, can solve the problems of complex methods and performance impact of lithium-ion capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

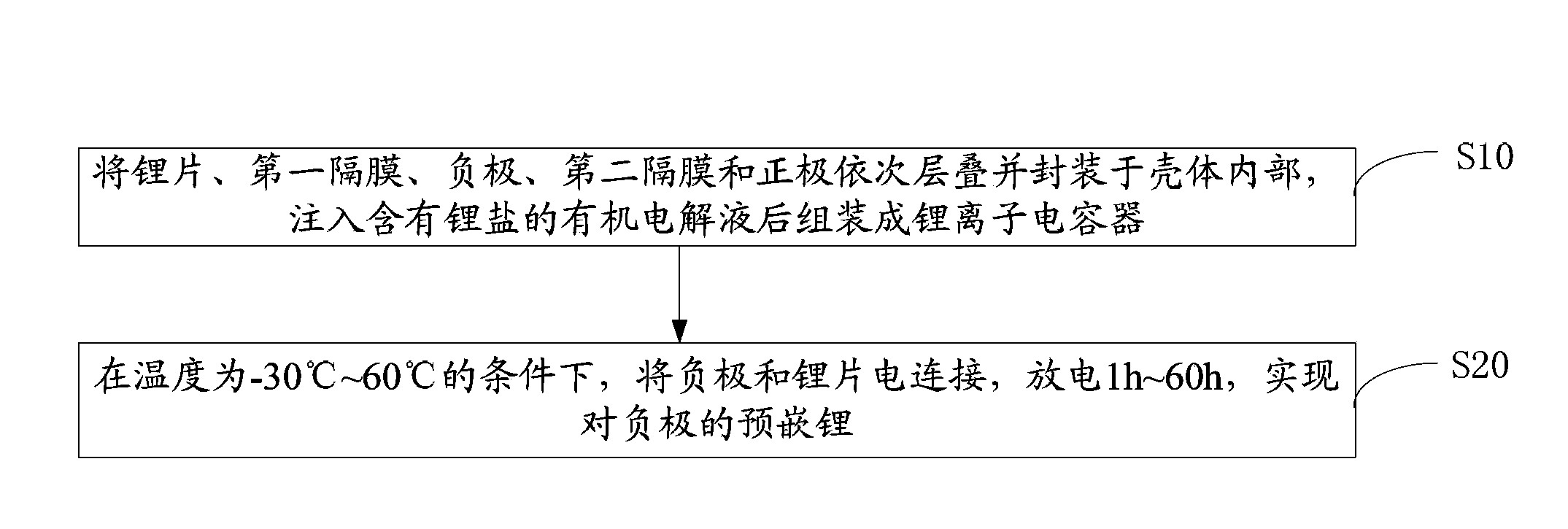

Method used

Image

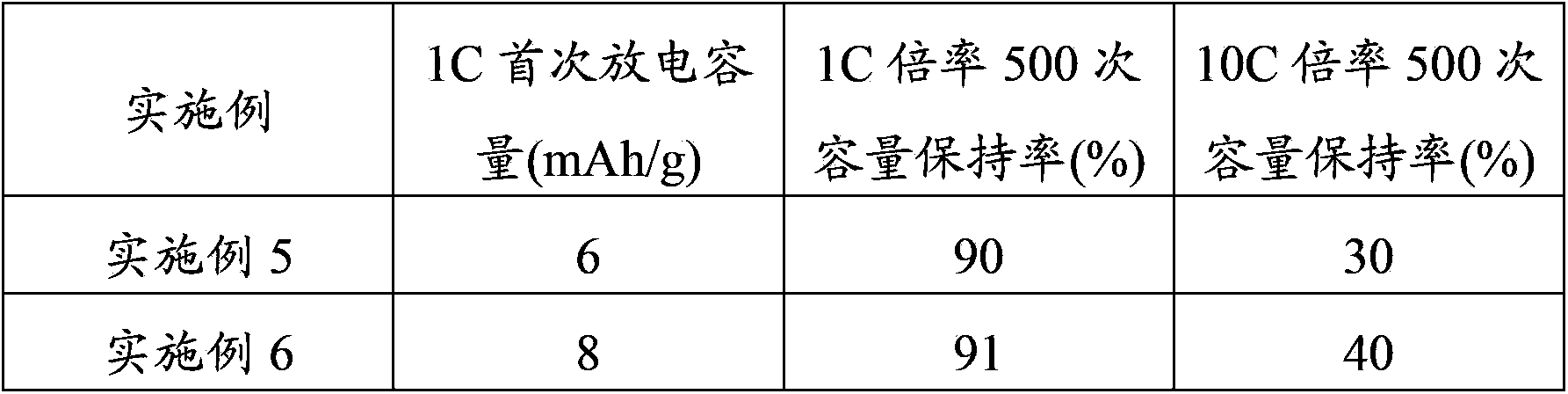

Examples

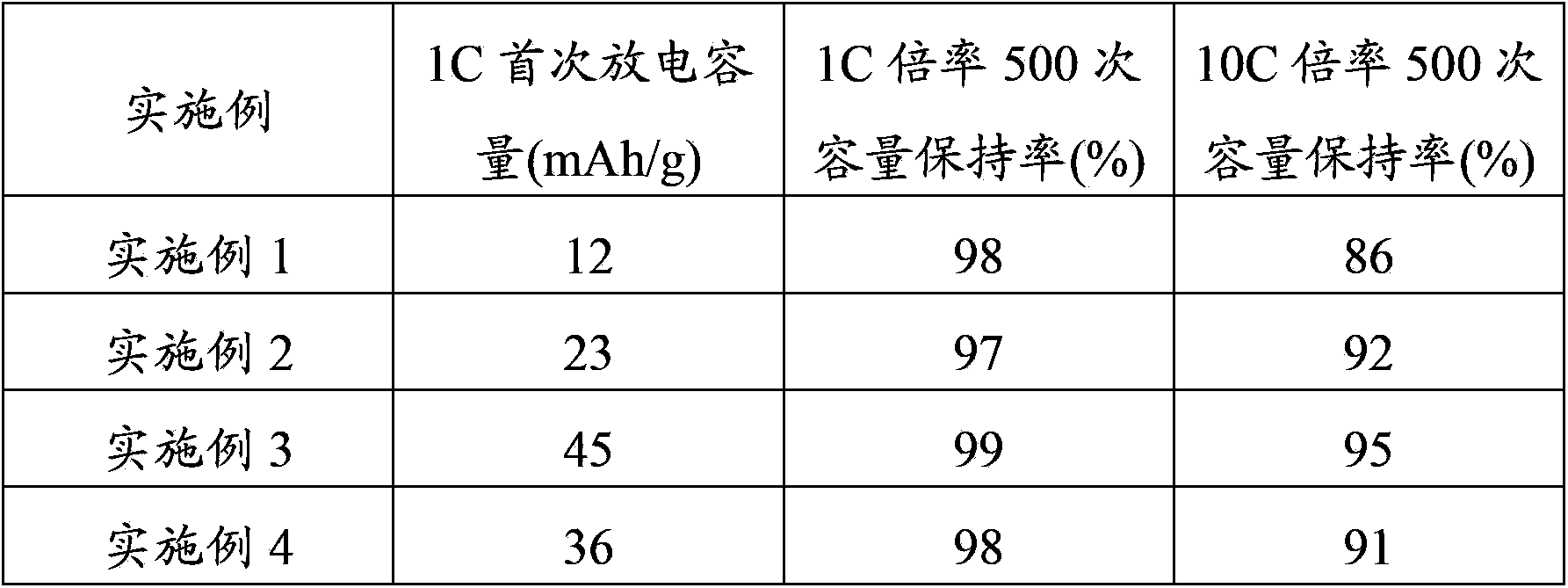

Embodiment 1

[0039] Activated carbon was used as the positive electrode, natural graphite was used as the negative electrode, a lithium sheet with a thickness of 0.1mm was used as the third electrode, and LiPF with a concentration of 1M 6 Dimethyl carbonate and propylene carbonate (volume ratio 1:1) were used as electrolytes to assemble lithium-ion capacitors. Under the condition of a temperature of 25°C, the lithium sheet and the negative electrode were directly short-circuited with a wire, and discharged for 30 hours to complete the lithium intercalation of the negative electrode. Then carry out cycle charge and discharge test on the lithium ion capacitor, the voltage range is 2V~4V.

Embodiment 2

[0041] The method of pre-intercalating lithium in the negative electrode of the lithium ion capacitor of Example 2 and Example 1 is basically the same, except that the thickness of the lithium sheet used as the third electrode is 0.2 mm.

Embodiment 3

[0043] The method of pre-intercalating lithium in the negative electrode of the lithium ion capacitor of Example 3 and Example 1 is basically the same, except that the thickness of the lithium sheet used as the third electrode is 0.3 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com