Damper piston and manufacturing process thereof

A preparation process and technology for shock absorbers, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc. The tolerance and accuracy of parts are difficult to meet the technical requirements, and the product standard requirements cannot be met, so as to achieve the effect of fewer preparation process steps, improved hardness and wear resistance, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

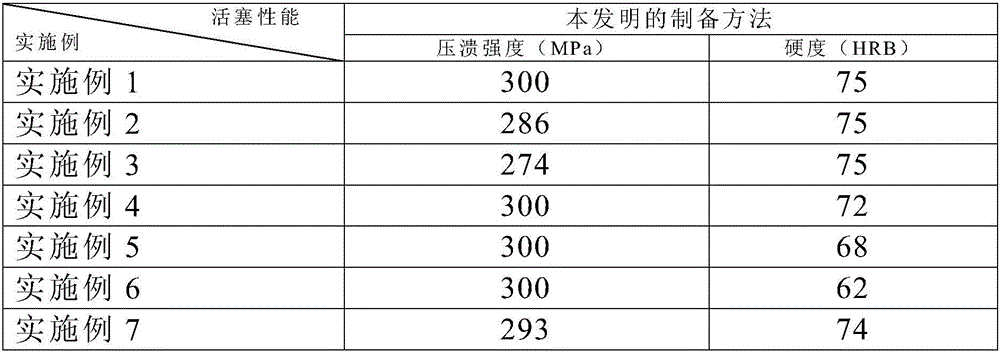

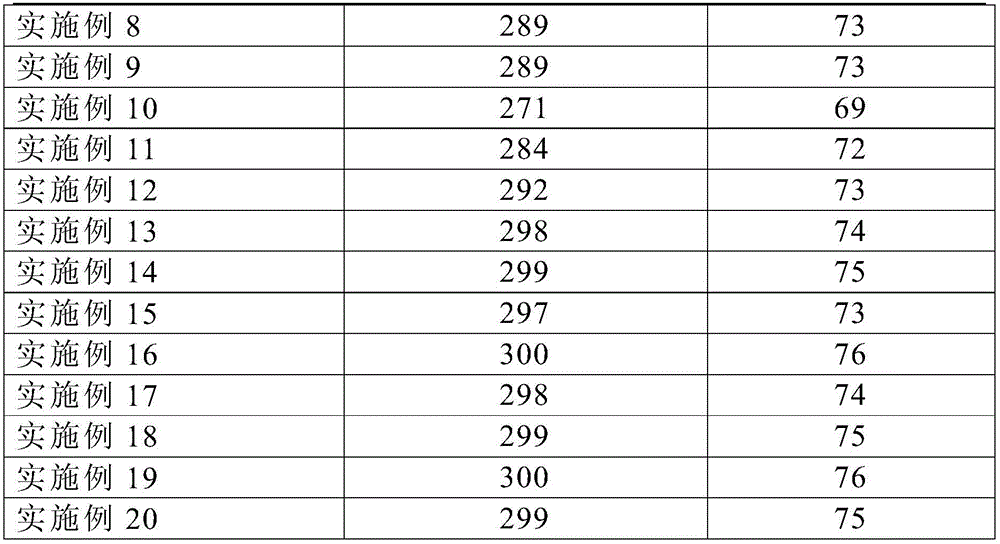

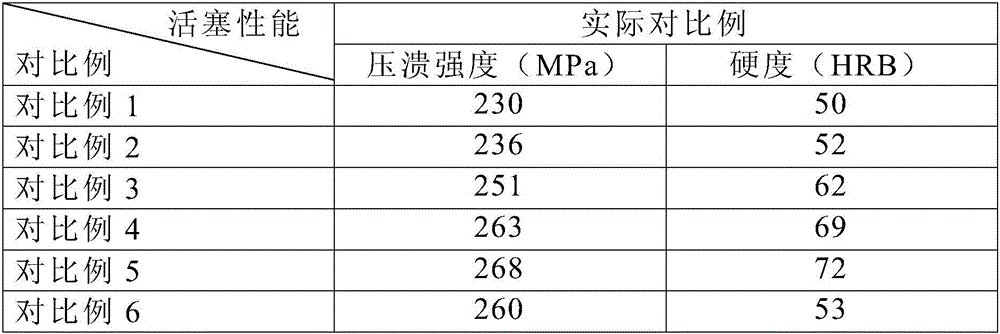

Examples

Embodiment 1

[0032] Ingredients: raw materials are weighed according to the composition and mass percentage of the piston in claim 1, 40% of tin-containing bronze powder, 1% of carbon powder, 1% of manganese sulfide, 0.25% of cerium dioxide, 4% of boron carbide, and the balance is iron . Grind the weighed materials into powder respectively, wherein the tin bronze powder has a particle size of 180 mesh, and the iron powder has a particle size of 120 mesh, and then put the powder into a mixer and stir for 1 hour to obtain a mixture. Put the mixed material into a powder metallurgy mold, and keep it under 750MPa pressure for 2 minutes to obtain a piston blank.

[0033] Sintering: Send the piston blank through the sintering mesh into a sintering furnace filled with protective gas for sintering, sintering at 1000°C for 1.5h, and finally cooling down to room temperature at a constant speed of 4°C / min to obtain the product. First, the sintered and cooled products are sent to the oil immersion mac...

Embodiment 2-3

[0036] The only difference from Example 1 is that the content of the ingredient ceria in Examples 2-3 is respectively 0.2% and 0.3%.

Embodiment 4-6

[0038] The only difference from Example 1 is that the contents of boron carbide in the ingredients in Examples 4-6 are 3%, 5%, and 6%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com