Ceramic bearing

A technology of ceramic bearings and inner rings, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of high cost, poor heat resistance, and poor friction reduction, and achieve good friction reduction, good heat resistance, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

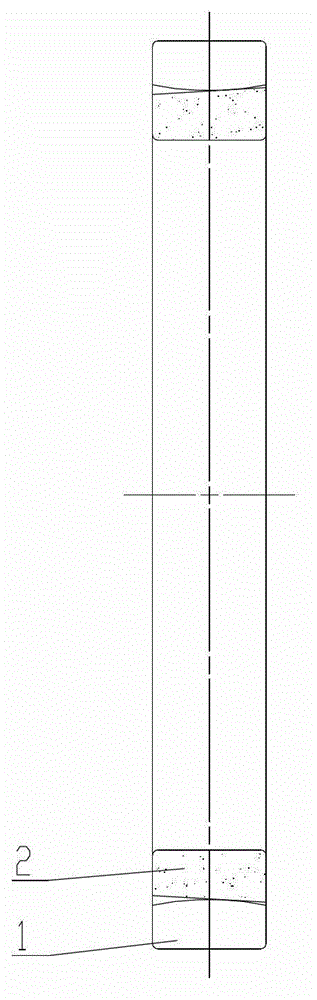

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] refer to Figure 1 ~ Figure 3 , a ceramic bearing, including an outer ring 1 and an inner ring 2, the inner ring 2 is nested in the outer ring 1, the inner hole of the outer ring 1 is an inverse spherical surface, and the outer surface of the inner ring 2 is a conical surface , the inclination angle of the tapered surface is 5-10°, and the centerline of the inner hole of the outer ring 1 is in contact with the neutral line of the outer side of the inner ring 2 .

[0015] Further, the inclination angle of the tapered surface is 6-8°.

[0016] In this embodiment, the shape of the inner hole of the outer ring (anti-spherical surface) and the shape of the outer diameter of the inner ring (conical surface) are changed to reduce friction, facilitate processing and withstand axial force.

[0017] In this embodiment, nano ceramic materials are preferably used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com