Dispersant viscosity index improver for enhanced wear protection of engine oils

A technology of engine oil and dispersant, applied in the directions of additives, petroleum industry, lubrication indicating device, etc., can solve problems such as poor fuel economy and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

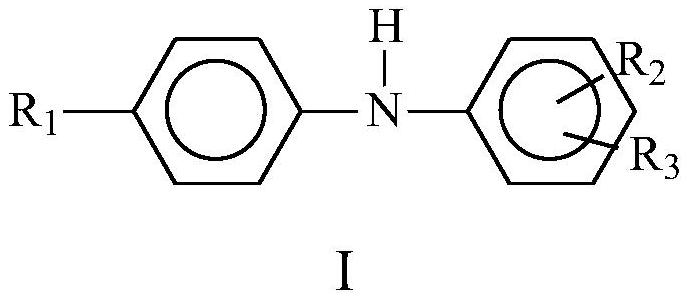

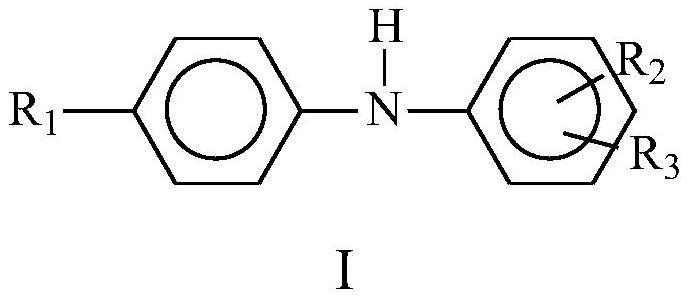

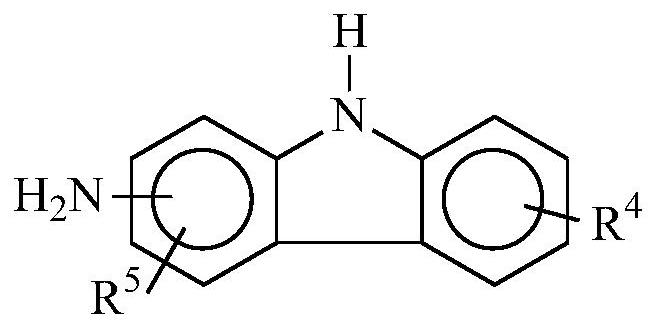

Method used

Image

Examples

example

[0300] The following examples are illustrative and not limiting of the methods and compositions of the present disclosure. In the following examples, the effect of incorporating a dispersant viscosity index improver (DVII) in an engine oil composition on soot treatment, wear protection and sludge treatment was determined. The DVII used in these examples is an amine functionalized olefin copolymer dispersant viscosity index improver comprising the reaction product of an acylated ethylene-propylene copolymer and a polyamine compound as described herein.

[0301] Table 3 summarizes the components used in Examples 1-6.

[0302] table 3

[0303]

[0304]

[0305] The engine oils of Examples 1-6 were tested using the OM646LA wear test to evaluate wear protection in the engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com