Hydraulic oil composition

A technology of working oil and composition, applied in the direction of lubricating composition, petroleum industry, thickener, etc., can solve the problem of insufficient sludge resistance, wear resistance, friction characteristics, water separation and friction reduction of sliding parts. and other problems, to achieve the effect of good energy performance and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

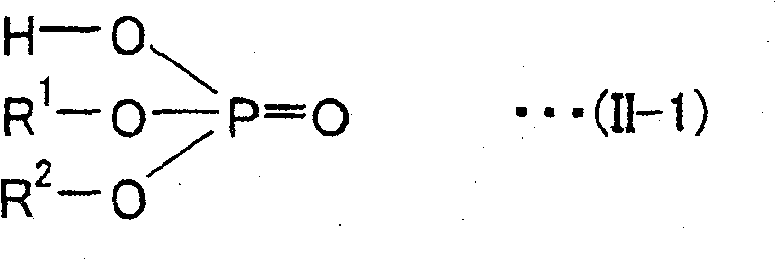

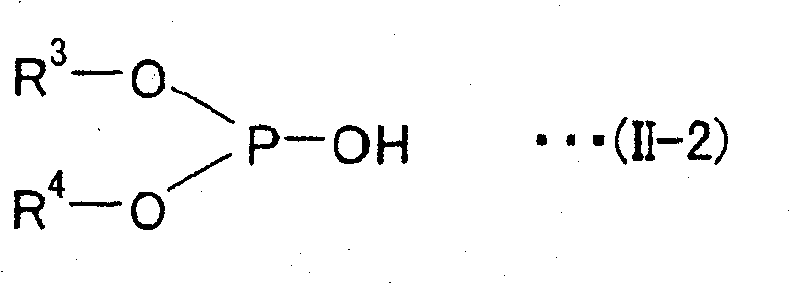

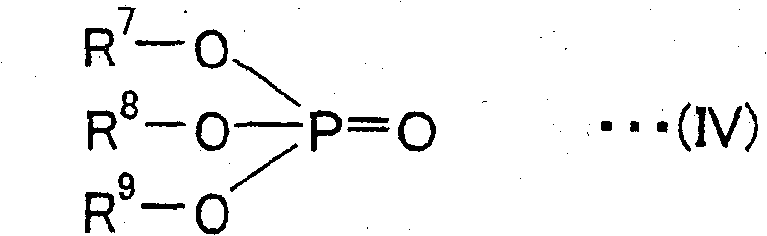

Method used

Image

Examples

Embodiment 1~4 and comparative example 1

[0170] Each hydraulic fluid composition having the composition shown in Table 1 was prepared, and the performance was evaluated. The results are shown in Table 1.

[0171] In addition, in Comparative Example 1, a Zn-based commercial oil (hydraulic hydraulic oil) having a viscosity index of 108 was used.

[0172] Table 1

[0173]

[0174] The following facts can be known from Table 1.

[0175] As a result of the high-pressure vane pump test, Examples 1 to 4 all have excellent power consumption and mechanical efficiency. As a result of the FZG test, Examples 1 to 4 all satisfy the ISO standard 10 or higher. As a result of thermal stability, the precipitation amount of the sludge of Examples 1 to 4 was extremely small compared to the Zn-based commercial oil of Comparative Example 1. As a result of the water separability test, it can be confirmed that Examples 1 to 4 can maintain good water separability. As a result of the bonding test, compared with the rubber material, Examples 1 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com