Liquefied polymer fracturing liquid thickener and preparation method thereof

A fracturing fluid thickener and liquefaction technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing the consumption of manpower and material resources, affecting the quality of base fluid, and insufficient fracturing fluid volume. Achieve the effect of reducing manpower and material resources input, avoiding waste of liquid preparation, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

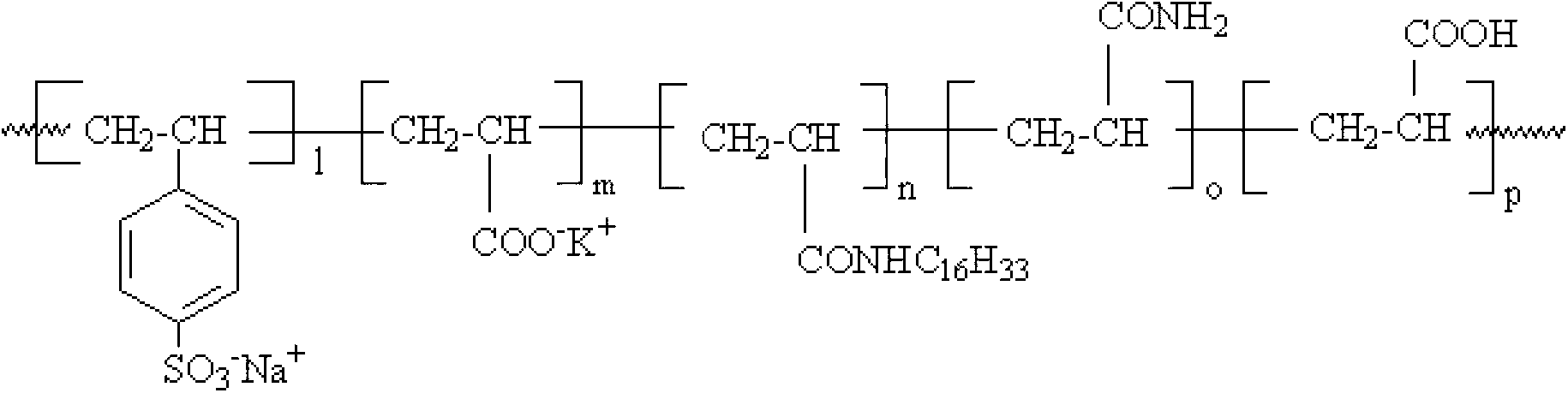

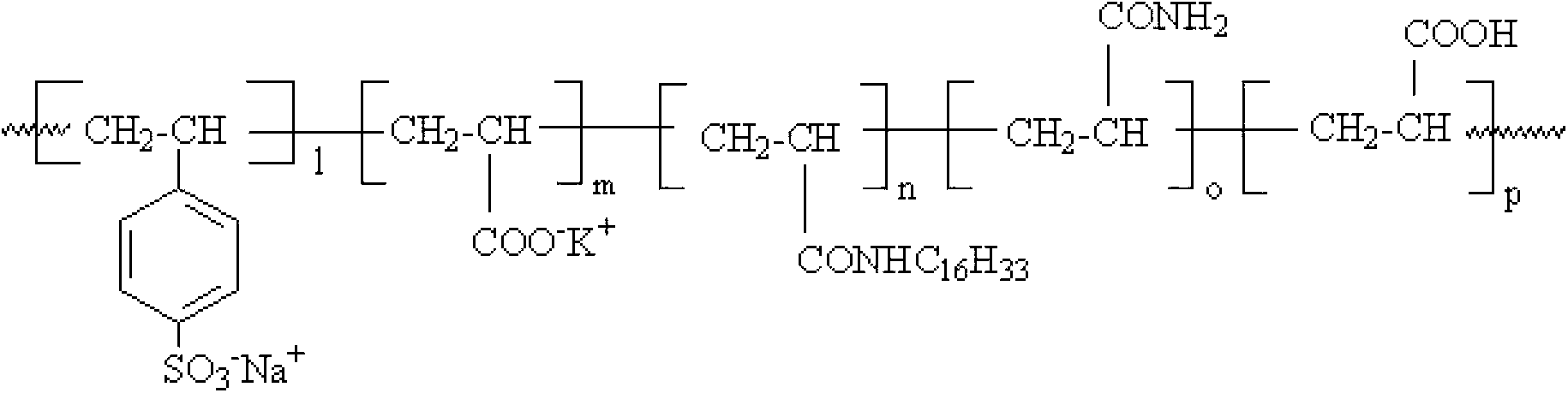

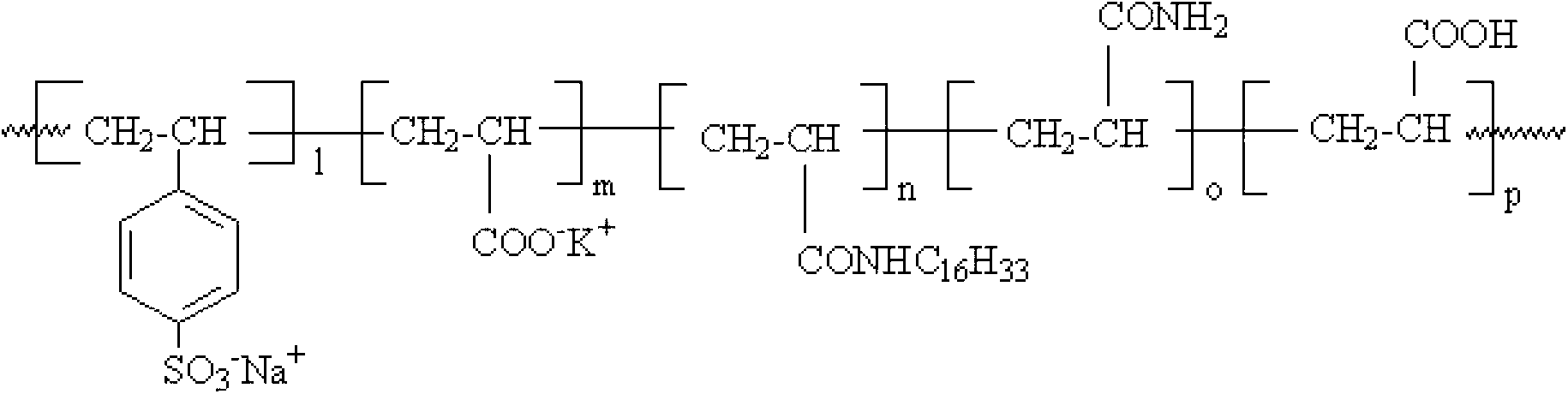

Image

Examples

preparation example Construction

[0063] Specifically, the preparation method of the liquefied thickener of the present invention comprises the following steps:

[0064] The first step: compounding of water-soluble organic solvents

[0065] Keep the temperature in the kettle at 10-30°C, and sequentially add sulfoxide organic solvents (including but not limited to one or more of dimethyl sulfoxide, dibutyl sulfoxide, n-butyl sulfoxide, etc.) ), amide organic solvents (including but not limited to one or more of dimethylformamide, dimethylacetamide, diethylformamide, etc.), monohydric alcohol organic solvents (including but not limited to ethanol, One or more of n-propanol, isobutanol, etc.) or polyhydric alcohol organic solvents (including but not limited to one or more of ethylene glycol, propylene glycol, glycerol, etc.), formate (including But not limited to one or more of sodium formate, potassium formate, etc.), forming a compound organic solvent system. In the compound system, based on the total mass of...

Embodiment 1

[0076] Preparation and performance test of liquid thickener 1:

[0077] 1) Weigh 78g of dimethyl sulfoxide in the kettle and keep stirring; add 34.6g of dimethylacetamide and stir for 20min; add 15g of n-propanol and 18g of isopropanol and stir for 30min; add 4.5g of sodium formate and stir 10min to obtain the compounded water-soluble organic solvent.

[0078] 2) Keep stirring, add 127.8 g of fracturing fluid thickener powder, and stir for 20 minutes to obtain liquefied thickener 1.

[0079] The product in this embodiment is an emulsion dispersion, and after testing, the density is 1.13g / cm 3 , the gelling time is 15s, and the viscosity of 1.0% liquefied thickener after dissolving is 42mPa.s.

Embodiment 2

[0081] Preparation and performance test of liquid thickener 2:

[0082] 1) Weigh 116g of dibutyl sulfoxide in the kettle and keep stirring; add 24g of dimethylformamide and 26g of diethylformamide and stir for 15min; add 24g of ethanol and stir for 15min; add 10g of potassium formate and stir for 15min , to obtain a compounded water-soluble organic solvent.

[0083] 2) Keep stirring, add 244.4 g of fracturing fluid thickener powder, and stir for 25 minutes to obtain liquefied thickener 2.

[0084] The product in this embodiment is an emulsion dispersion, and after testing, the density is 1.24g / cm 3 , the gelling time is 15s, and the viscosity of 1.0% liquefied thickener after dissolving is 56mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com