Preparation method of cast nylon composite material with high anti-friction and anti-wear surface layer

A technology of anti-friction and anti-wear cast nylon, which is applied in the field of preparation of cast nylon composite materials, can solve the problems of decreased tensile strength, increased brittleness of filling system, etc., and achieves the effect of enhancing self-lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

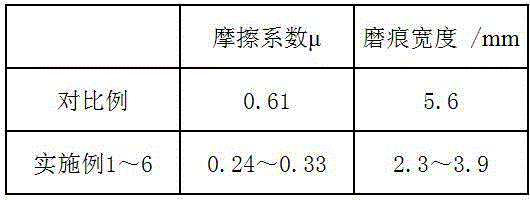

Examples

Embodiment 1

[0018] Embodiment 1: prepare composite material according to the following specific steps

[0019] (1) Preparation of dispersed colloids: 800g of purified hexamethylphosphoric triamide, 50g of heat-treated ultrafine kaolin and 50g of toluene diisocyanate were accurately measured respectively, placed in a stirring reactor, and protected by dry nitrogen , fully stirred, and reacted at 80°C and normal pressure for 4 hours to obtain a dispersed colloid, cooled the dispersed colloid to normal temperature, and stored it in a desiccator filled with anhydrous calcium chloride for later use;

[0020] (2) Preparation of concentrated reactive material: Put 1000g of caprolactam monomer and 3.0g of sodium hydroxide into a stainless steel active material kettle at the same time, reduce the pressure to 1.33kPa, react at 120°C, distill to remove moisture, and maintain the reduced pressure state for 30min. To obtain the concentrated reactive material containing caprolactam sodium salt, remove ...

Embodiment 2

[0023] Embodiment 2: Prepare composite material according to the following specific steps

[0024] (1) Preparation of dispersed colloid: same as step (1) of Example 1;

[0025] (2) Preparation of concentrated reactive material: put 1000g of caprolactam and 4.5g of sodium hydroxide into a stainless steel active material kettle, reduce the pressure to 1.33kPa, react at 126°C, remove water by distillation, and maintain the reduced pressure state for 30min to obtain sodium caprolactam For the concentrated reactive material of salt, remove the vacuum, pass dry nitrogen to normal pressure, and keep the temperature of the concentrated reactive material at 165°C;

[0026] (3) Preparation of synergistically modified composite materials: put 2000g caprolactam into a stainless steel batching kettle, reduce the pressure to 1.33kPa, distill and remove moisture at 130°C, maintain the reduced pressure state for 20min, release the vacuum, and pass dry nitrogen to normal pressure , then add 2...

Embodiment 3

[0028] Embodiment 3: prepare composite material according to the following specific steps

[0029] (1) Preparation of dispersed colloid: same as step (1) of Example 1;

[0030] (2) Preparation of concentrated reactive material: put 1000g of caprolactam and 6.0g of sodium hydroxide into a stainless steel active material kettle, reduce the pressure to 1.33kPa, react at 135°C, remove water by distillation, and maintain the reduced pressure state for 30min to obtain caprolactam For the concentrated reactive material of sodium salt, the vacuum is released, dry nitrogen is introduced to normal pressure, and the temperature of the concentrated reactive material is kept at 170°C;

[0031] (3) Preparation of synergistically modified composite materials: Put 2000g caprolactam into a stainless steel batching kettle, reduce the pressure to 1.33kPa, distill and remove moisture at 135°C, maintain the reduced pressure state for 20min, release the vacuum, and pass dry nitrogen to normal press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com