Water-based lubricating nanometer metal antifriction and wear resistant intensifying agent

A nano-metal, anti-friction and anti-wear technology, applied in the direction of lubricating compositions, etc., can solve the problems of poor dispersion stability, complicated manufacturing process, poor compatibility, etc., and achieve easy large-scale industrial production, stable system properties, strengthened Anti-friction and anti-wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: anti-friction and anti-wear nano-silver reinforcing agent of water-based lubrication:

[0023] 100 parts of water-isopropanol-polyethylene glycol with a volume ratio of 20:20:60, 0.5 part of polyvinylpyrrolidone (PVP), 0.05 part of sodium dodecylsulfonate, 0.0005 part of nano silver powder (particle size 1~ 100 nm) at 40°C for 120 min to obtain a transparent dark reddish-brown sol.

Embodiment 2

[0024] Embodiment 2: anti-friction and anti-wear nano-lead fortifier of water-based lubrication:

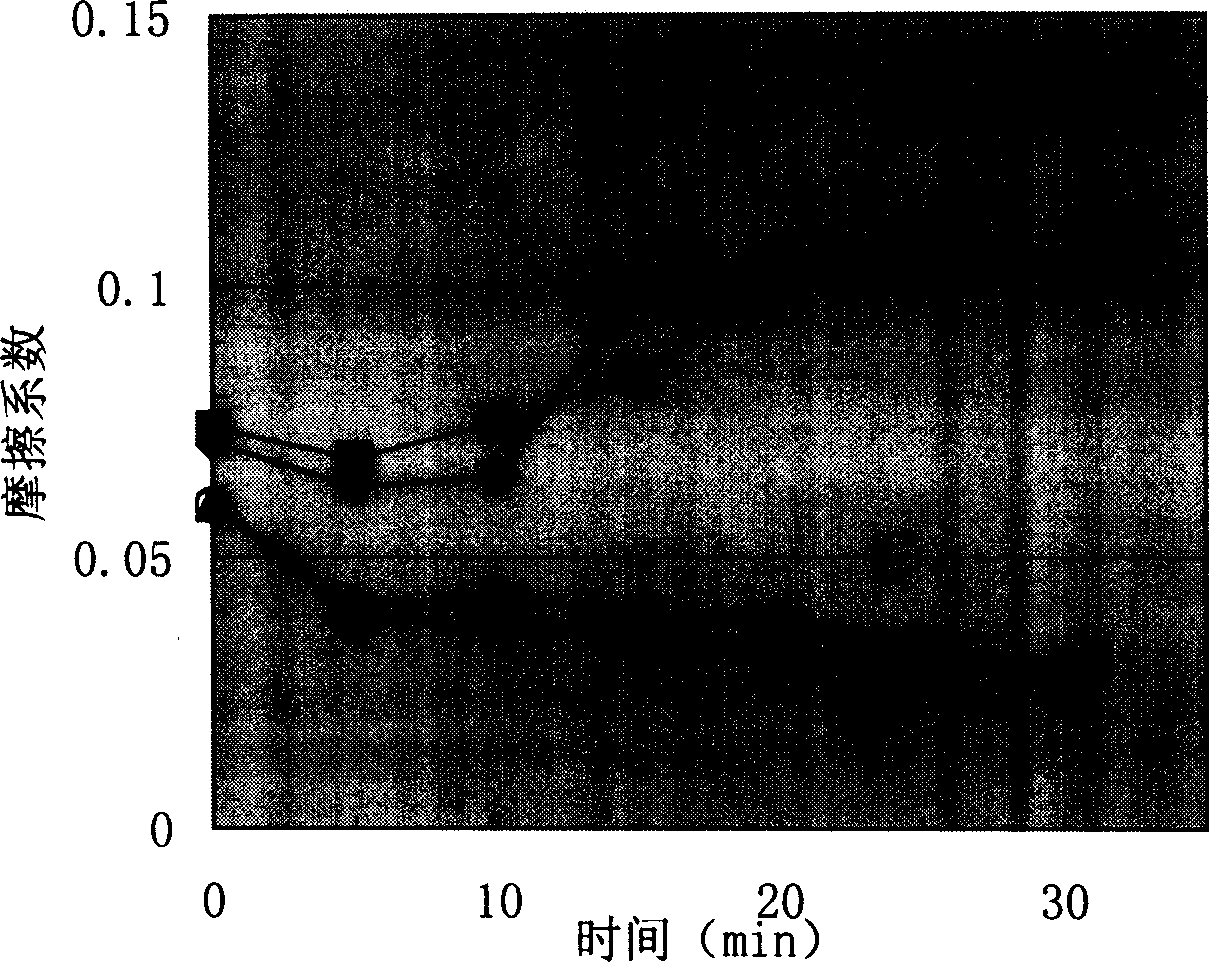

[0025] Using 0.5 parts of nano-lead powder (particle size 1-100nm) as raw material, the conditions are the same as in Example 1, and the four-ball evaluation results when 5 parts of strengthening agent is added to 25 parts of ethylene glycol are shown in Appendix D.

Embodiment 3

[0026] Embodiment 3: Anti-friction and anti-wear nano-copper reinforcing agent of water-based lubrication:

[0027] Using 0.1 part of nano-copper powder (particle size 1-100nm) as raw material, the conditions are the same as in Example 1, and the four-ball evaluation results when 5 parts of strengthening agent are added to 25 parts of ethylene glycol are shown in Appendix C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com