Xanthophylls nano dispersion liquid with control release property as well as preparation method

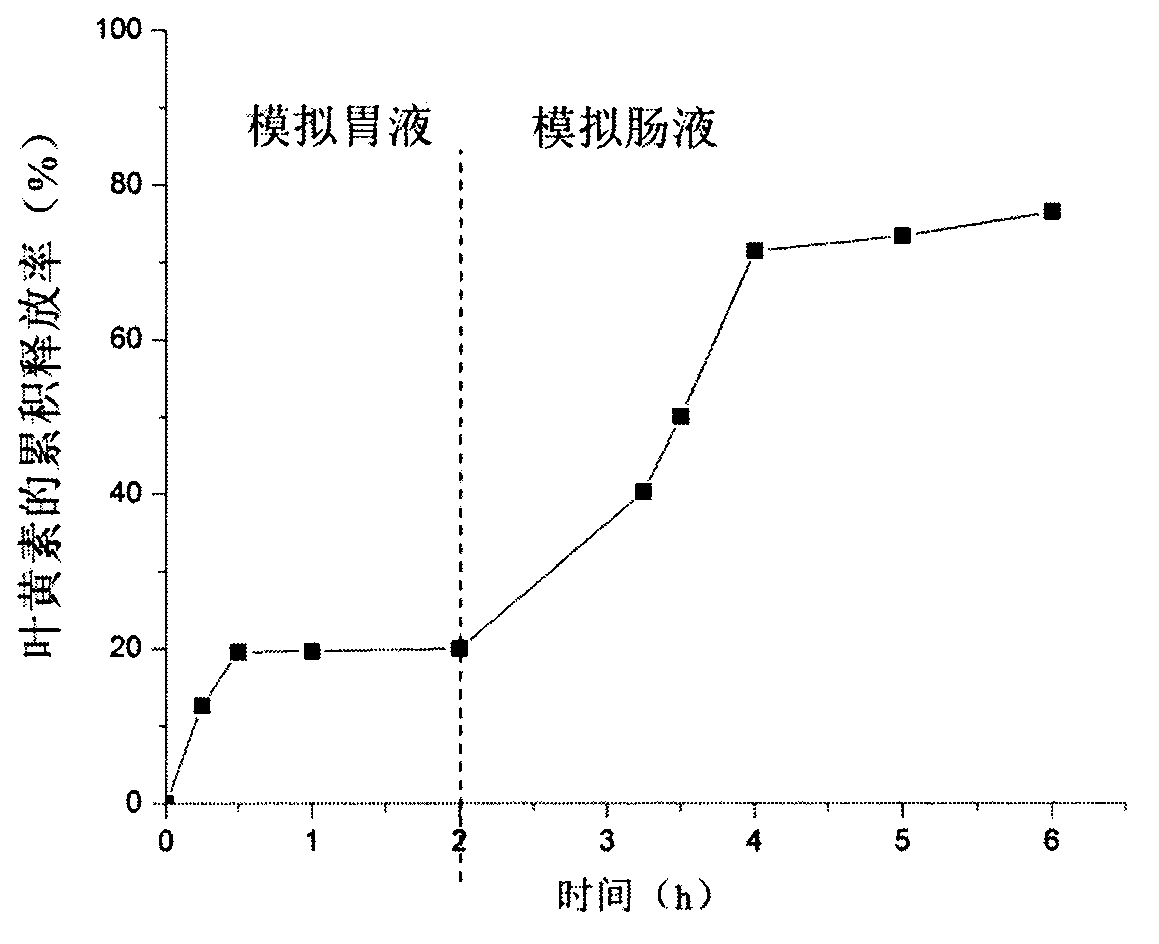

A nano-dispersion, lutein technology, used in food preparation, application, food science and other directions, can solve problems such as poor solubility and emulsifying properties, pepsin sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Accurately weigh 0.8g of casein, 5.6g of dextran (40kDa) and dissolve in 100mL 1 / 15mol / L phosphate buffer, stir to make a homogeneous solution with casein mass concentration of 8g / L, freeze-dry for 24h . The dried sample was ground, passed through a 120-mesh sieve, placed in a petri dish, sealed with perforated aluminum foil, and reacted (60°C, relative humidity 78%, pH 7.0) for 20 hours, then cooled to terminate the reaction. Repeat ultrafiltration three times with an ultrafiltration membrane with a cut-off molecular weight of 100kDa, collect components larger than 100kDa and freeze-dry to obtain the casein-dextran copolymer.

Embodiment 2

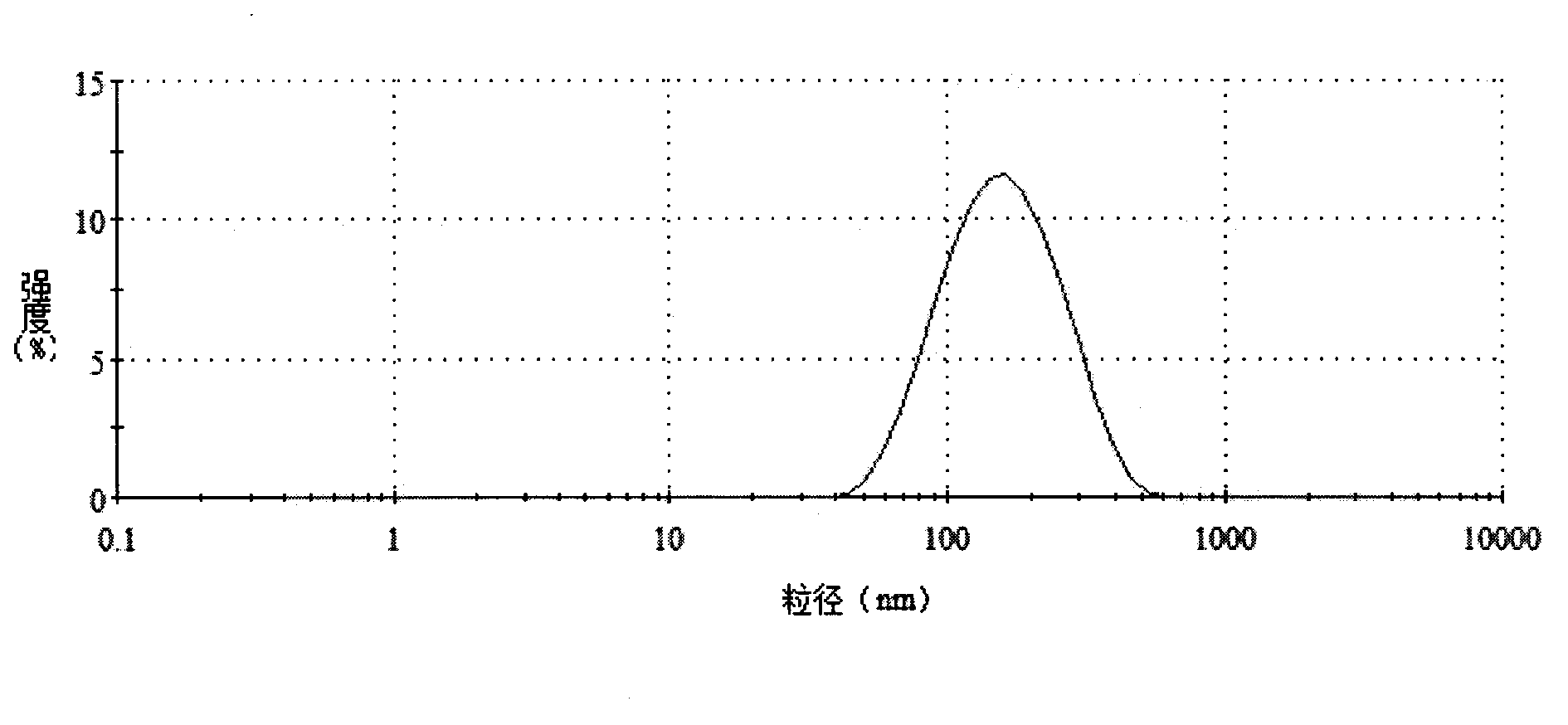

[0021] Dissolve the above copolymer in water at 55°C (the content of casein is 1g / L), stir for 1h, dissolve 0.005g lutein in ethanol (10mL) and quickly inject it into 100mL aqueous copolymer solution, continue stirring for 30min, and remove the ethanol by rotary evaporation (55°C, vacuum degree 0.1MPa), cooling rapidly, adjusting the pH to 4.6, and then undergoing ultra-high pressure homogenization treatment (under the condition of 1000-1400bar, cycled 5 times) to obtain the lutein nano-dispersion. The measured average particle diameter is 141.3nm, the polydispersity index is 0.209, and the encapsulation efficiency is 94.2%.

Embodiment 3

[0023] Dissolve the above copolymer in water at 55°C (the content of casein is 5g / L), stir for 1h, dissolve 0.025g lutein in ethanol (50mL) and quickly inject it into 100mL aqueous copolymer solution, continue stirring for 30min, and remove the ethanol by rotary evaporation (55°C, vacuum degree 0.1MPa), cooling rapidly, adjusting the pH to 4.6, and then undergoing ultra-high pressure homogenization treatment (under the condition of 1000-1400bar, cycle 4 times) to obtain the lutein nano-dispersion. The measured average particle diameter is 129.2nm, the polydispersity index is 0.321, and the encapsulation efficiency is 94.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com