Micro-emulsion calcium preparation and preparation method as well as application thereof

A microemulsion and preparation technology, which is applied in the field of microemulsion calcium preparation and its preparation, can solve the problem of inability to co-dissolve bioavailability of calcium preparations, and achieve the effect of promoting calcium absorption and reducing the amount of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 microemulsion calcium supplement preparation

[0036] Weigh each component according to the following weight: Tween-805g, soybean lecithin 0.5g, sorbitol 1g, ethanol 0.5g, vitamin AD 1g, calcium gluconate 10g;

[0037] Dissolve soybean lecithin in ethanol, slowly add Tween under stirring, and put in water bath at 40°C; add vitamin AD oil to the above mixture, put in water bath at 40°C, stir to obtain mixed liquid I, and set aside. Dissolve sorbitol and calcium gluconate in an appropriate amount of distilled water, heat appropriately (for example, 30-50° C.), and stir until clear to obtain a mixed solution II. Slowly add the mixed solution II into the mixed solution I, and stir to obtain a clear and transparent microemulsion calcium preparation.

[0038] The particle size of the prepared microemulsion calcium preparation measured by a Malvern laser particle size analyzer is 15.4nm.

Embodiment 2

[0039] The preparation of embodiment 2 microemulsion calcium supplement preparation

[0040] Weigh each component according to the following weight: Tween-80 20g, soybean lecithin 2g, sorbitol 10g, ethanol 2g, vitamin AD 10g, calcium gluconate 50g;

[0041] Dissolve soybean lecithin in ethanol, slowly add Tween under stirring, and put in water bath at 40°C; add vitamin AD oil to the above mixture, put in water bath at 40°C, stir to obtain mixed liquid I, and set aside. Dissolve sorbitol and calcium gluconate in an appropriate amount of distilled water, heat appropriately (for example, 30-50° C.), and stir until clear to obtain a mixed solution II. Slowly add the mixed solution II into the mixed solution I, and stir to obtain a clear and transparent microemulsion calcium preparation.

[0042] The particle size of the prepared microemulsion calcium preparation measured by a Malvern laser particle size analyzer is 11.8nm.

Embodiment 3

[0043] The preparation of embodiment 3 microemulsion calcium supplement preparation

[0044] Weigh each component according to the following weight: Tween-80 10g, soybean lecithin 1.5g, sorbitol 6g, ethanol 1.0g, vitamin AD 5g, calcium gluconate 25g;

[0045]Dissolve soybean lecithin in ethanol, slowly add Tween under stirring, and put in water bath at 40°C; add vitamin AD oil to the above mixture, put in water bath at 40°C, stir to obtain mixed liquid I, and set aside. Dissolve sorbitol and calcium gluconate in an appropriate amount of distilled water, heat appropriately (for example, 30-50° C.), and stir until clear to obtain a mixed solution II. Slowly add the mixed solution II into the mixed solution I, and stir to obtain a clear and transparent microemulsion calcium preparation.

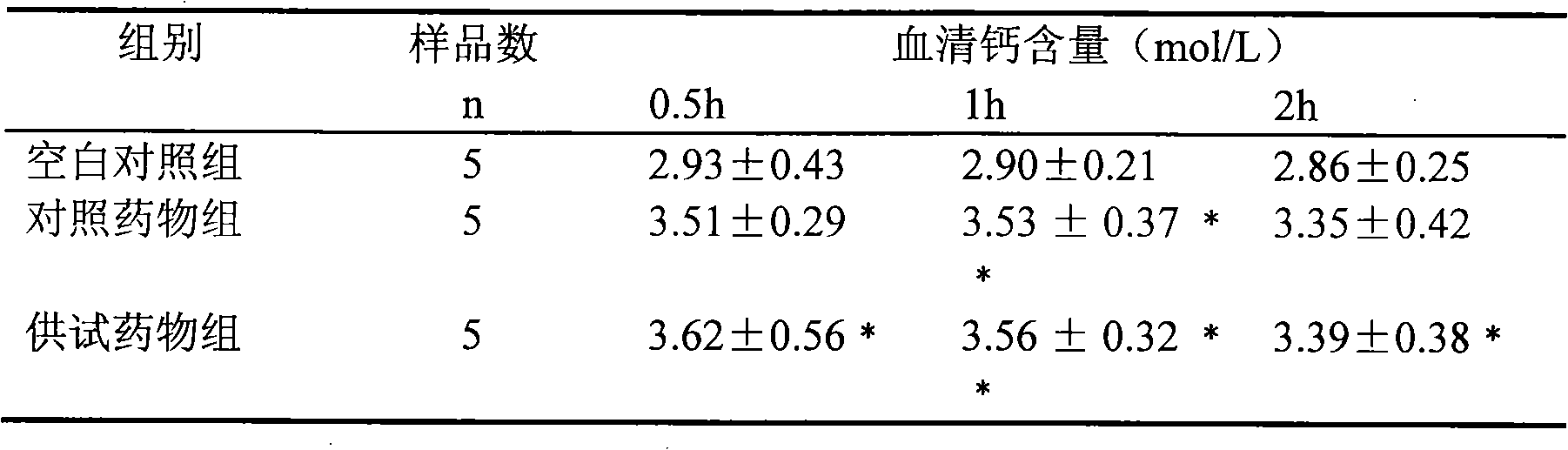

[0046] The particle size of the prepared microemulsion calcium preparation measured by a Malvern laser particle size analyzer is 16.5nm. Test example 1 the influence of microemulsion calcium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com