A kind of preparation method of alkali-free and chlorine-free liquid quick-setting agent

An accelerator and liquid technology, applied in the field of building materials, can solve the problems of hindering the commercial application of accelerators and high requirements on raw material particle size, and achieve the effect of improving adaptability and later strength, optimizing performance and stable system properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

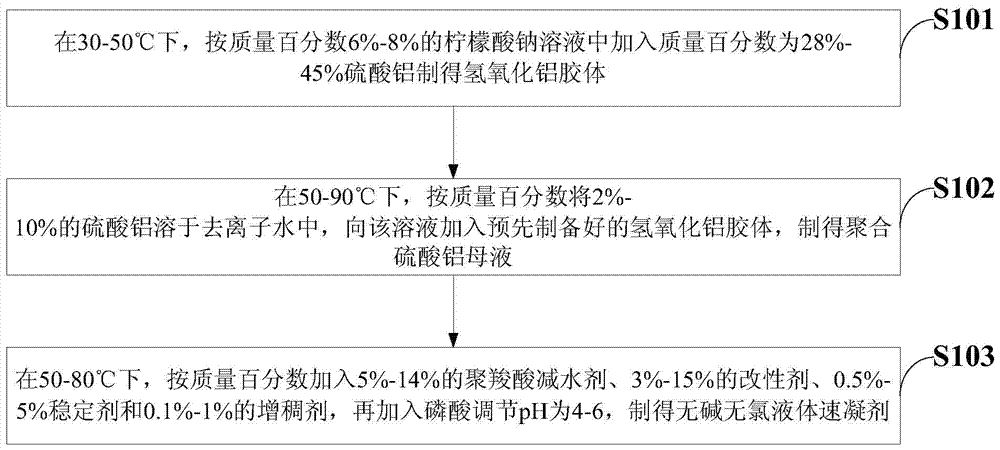

Method used

Image

Examples

Embodiment 1

[0030] Add deionized water to the pulverized and dried bentonite and stir to form a suspension with a mass fraction of 15%, then add a polyethylene glycol solution with a mass fraction of 5% to the above suspension and mix evenly, and place it in the React at 70°C for 1 hour, filter with suction, dry and grind to obtain modified bentonite. At 30°C, add 28% aluminum sulfate to the sodium citrate solution with a mass fraction of 6% to prepare aluminum hydroxide colloid, and at 50°C, dissolve 2% aluminum sulfate in deionized water, and add pre- The prepared aluminum hydroxide colloid is prepared as a polyaluminum sulfate mother liquor, and at 50°C, 5% of polycarboxylate water reducer and 3% of polyethylene glycol-modified bentonite are added to the above polyaluminum sulfate mother liquor As a modifying agent, 0.5% stabilizer and 0.1% thickener, after adding phosphoric acid to adjust the pH to 4-6, the alkali-free and chlorine-free liquid quick-setting agent is prepared. When th...

Embodiment 2

[0032] Add deionized water to the pulverized and dried bentonite and stir to form a suspension with a mass fraction of 17%, then add a polyethylene glycol solution with a mass fraction of 7% to the above suspension and mix evenly, and place it in React in water at 75°C for 1 hour, filter with suction, dry and grind to obtain modified bentonite. At 35°C, add 34% aluminum sulfate to a 6% sodium citrate solution to obtain a colloid, and at 65°C, dissolve 4% aluminum sulfate in deionized water, and add pre-prepared Aluminum hydroxide colloid is used to prepare the mother liquor of polyaluminum sulfate. Under the condition of 55°C, 8% of polycarboxylate water reducer and 7% of bentonite modified by polyethylene glycol are added to the mother liquor of polyaluminum sulfate as modified agent, 1.5% stabilizer and 0.3% thickener, and phosphoric acid is added to adjust the pH to 4-6 to obtain an alkali-free and chlorine-free liquid quick-setting agent. When the amount of accelerator is...

Embodiment 3

[0034]Add deionized water to the pulverized and dried bentonite and stir to form a suspension with a mass fraction of 19%, then add a polyethylene glycol solution with a mass fraction of 8% to the above suspension and mix evenly, and place it in the React for 1.5 hours at 80°C in water, filter with suction, dry and grind to obtain modified bentonite. At 40°C, add 38% aluminum sulfate to a 7% sodium citrate solution to obtain a colloid, and at 70°C, dissolve 6% aluminum sulfate in deionized water, and add pre-prepared Aluminum hydroxide colloid is used to prepare the mother liquor of polyaluminum sulfate. Under the condition of 60°C, 10% of polycarboxylate water reducer and 10% of bentonite modified by polyethylene glycol are added to the mother liquor of polyaluminum sulfate as modified agent, 2.5% stabilizer and 0.4% thickener, and adding phosphoric acid to adjust the pH to 4-6 to obtain an alkali-free and chlorine-free liquid quick-setting agent. When the amount of accelera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com