Nanofiltration separation membrane and preparation method thereof

A separation membrane and nanofiltration technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem that cellulose derivatives are easily degraded by microorganisms, are not resistant to oxidation, and their stability and anti-pollution properties need to be improved and other problems, to achieve the effects of inhibiting membrane fouling, prolonging service life, and improving membrane water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

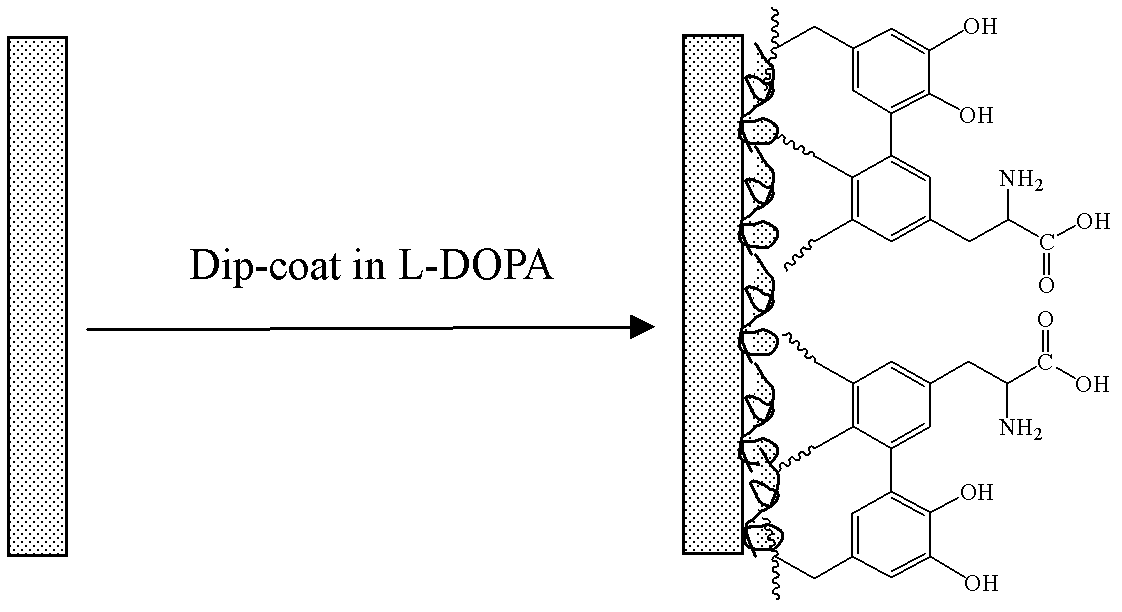

Method used

Image

Examples

Embodiment 1

[0036] Wash the polyacrylonitrile-based membrane with ethanol and deionized water alternately, then soak it fully in ethanol; dissolve dopa in deionized water, and prepare a dopa solution with a concentration of 2.0mg / L; soak the basement membrane in dopa solution, shaking in a shaking incubator with a rotation speed of 100r / min and a temperature of 35°C for 24h, and then alternately shaking and washing in ethanol and deionized water; Soak in polyethyleneimine for 3 hours, shake and wash in deionized water; then immerse the separation membrane obtained above in 0.5% glutaraldehyde solution at 60° C. for cross-linking for 6 hours; rinse with deionized water to prepare a nanofiltration separation membrane.

[0037] The performance of the separation membrane was measured and the results are as follows. For MgSO 4 Mixed solution with NaCl, the water flux is 30L / m 2 h, the rejection rate of magnesium ions is 72%, the rejection rate of sodium ions is 25%, and the selective rejecti...

Embodiment 2

[0039]Wash the polyacrylonitrile-based membrane with ethanol and deionized water alternately, and fully infiltrate it in ethanol; dopa is dissolved in a Tris-hydrochloric acid buffer solution with a pH of 8.0, and a dopa solution with a concentration of 1.0 mg / L is prepared; Soak the basement membrane in the dopa solution, shake it in a shaking incubator with a rotation speed of 100r / min and a temperature of 35°C for 24h, and then alternately shake and wash it in ethanol and deionized water; put the basement membrane with a polydopa composite layer Soak the membrane in polyethyleneimine at a temperature of 50°C for 3h, and shake and wash it in deionized water; then immerse the separation membrane obtained above in a 0.5% glutaraldehyde solution at 60°C for 6h; rinse with deionized water, and prepare A nanofiltration separation membrane was obtained.

[0040] The performance of the separation membrane was measured and the results are as follows. For MgSO 4 Mixed solution with...

Embodiment 3

[0042] Soak the polyacrylonitrile-based membrane statically in 0.5% NaOH aqueous solution for 4 hours, wash it alternately with ethanol and deionized water, and fully infiltrate it in ethanol; dissolve dopa in a Tris-hydrochloric acid buffer solution with a pH of 8.0, and configure Dopa solution with a concentration of 2.0mg / L; soak the basement membrane in the dopa solution, add 0.2g of zinc powder, shake in a shaking incubator with a rotation speed of 100r / min and a temperature of 35°C for 24h, and then in ethanol and Alternate shaking and cleaning in deionized water; soak the base membrane with polydopa composite layer in polyethyleneimine at a temperature of 50°C for 6h, shake and wash in deionized water; then immerse the separation membrane obtained above in a 60°C Cross-link in 1.0% glutaraldehyde solution for 12 hours; rinse with deionized water to prepare nanofiltration separation membrane.

[0043] The performance of the separation membrane was measured and the result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com