Underground gel-forming blocking agent suitable for medium-high temperature high-salt low-permeability reservoirs and preparation method therefor

An underground gelling and plugging agent technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of water resistance, environmental protection and safety of products, fast reaction speed, and low concentration of phenolic structure, and delay polycondensation and solidification Ability, improved impact resistance, and high chemical bond energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

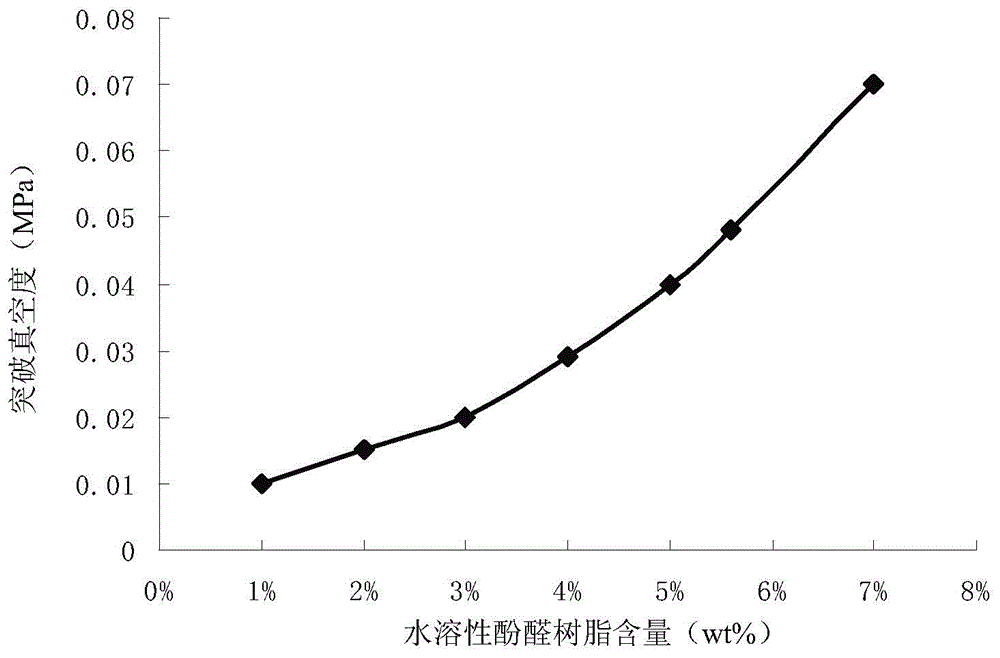

[0042]This embodiment provides a plugging agent, which is suitable for deep plugging of medium-temperature oil reservoirs. Based on the total weight of the plugging agent, its raw material composition is: polyacrylamide KYPAM (molecular weight is 26.48 million, and the degree of hydrolysis is 28 %) 0.1%, water-soluble phenolic resin (pH value greater than 11, solid content greater than 40wt%) 2%, p-toluenesulfonyl hydrazide 1%, and the balance is water.

[0043] The plugging agent is prepared by the following method: select each raw material according to the proportion, add KYPAM to an appropriate amount of water and stir evenly to form a solution, then mature at room temperature for 5 hours, then add water-soluble phenolic resin and p-methyl Benzenesulfonyl hydrazide, after stirring evenly, obtains the described plugging agent.

[0044] Plugging agent test:

[0045] The gelling time of the plugging agent at 70°C is 24 hours, and the rheological properties do not change much ...

Embodiment 2

[0050] This embodiment provides a plugging agent, which is suitable for deep plugging of high-temperature oil reservoirs. Based on the total weight of the plugging agent, its raw material composition is: water-soluble phenolic resin (pH value greater than 11, solid content greater than 40wt %) 2%, p-toluenesulfonyl semicarbazide 1%, and the balance is water.

[0051] The plugging agent is prepared by the following method: selecting raw materials according to the proportion, adding water-soluble phenolic resin and p-toluenesulfonylsemicarbazide into water, and stirring evenly to obtain the plugging agent.

[0052] Plugging agent test:

[0053] The plugging agent is a clear and transparent aqueous solution before it is gelled. It will not solidify after being placed at 80°C for 1 week. After standing at 120°C for 10h-14h, the solution will gradually turn into a mobile gel, and it will form a rigid gel after standing for 24h.

[0054] A delayed polycondensation test was carried ...

Embodiment 3

[0060] This embodiment provides a plugging agent, which is suitable for plugging high-temperature oil reservoirs. Based on the total weight of the plugging agent, its raw material composition is: water-soluble phenolic resin (pH value greater than 11, solid content greater than 40wt%) ) 2%, p-toluenesulfonyl semicarbazide 1%, and the balance is water.

[0061] The plugging agent is prepared by the following method: selecting raw materials according to the proportion, adding water-soluble phenolic resin and p-toluenesulfonylsemicarbazide into water, and stirring evenly to obtain the plugging agent.

[0062] Plugging agent test:

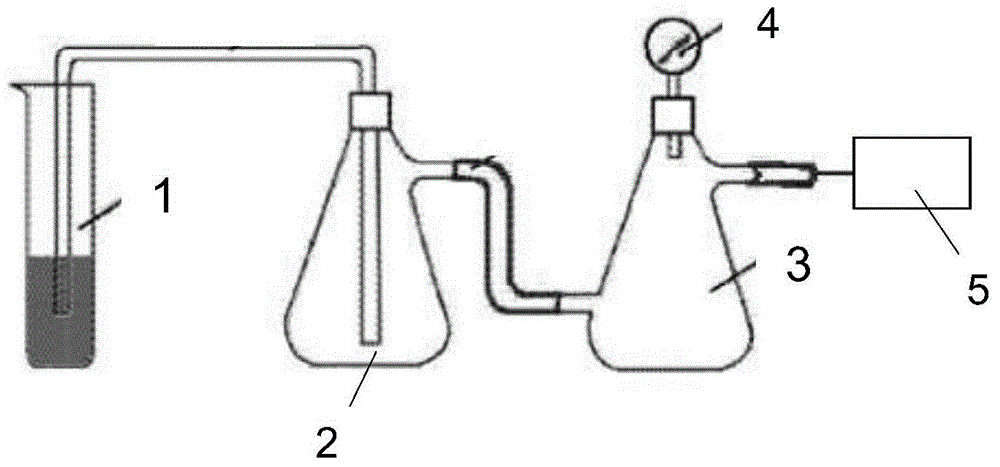

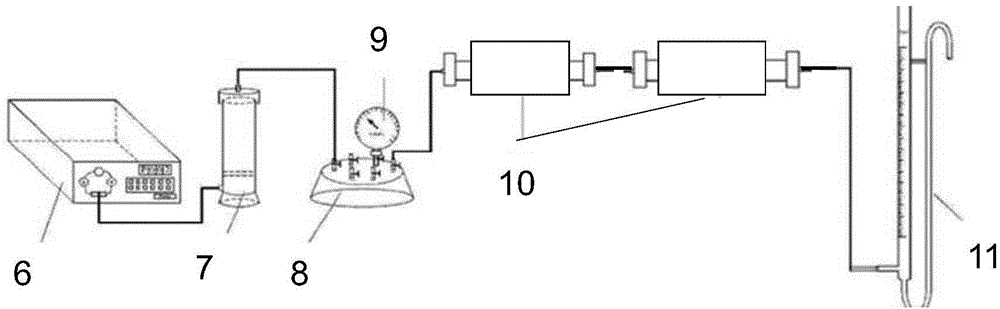

[0063] Carry out the core test of series sand-packing tubes on this plugging agent: fill two sand-packing tubes (tube length 25cm) with 70 mesh quartz sand, and connect them in series to figure 2 In the core displacement experimental device shown, after the temperature is raised to 120°C, 2PV plugging agent is injected at a displacement of 0.9mL / min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com