Flexible series-parallel imbricated photovoltaic module and manufacturing method thereof

A photovoltaic module and parallel technology, which is applied in the direction of photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limiting the use range of shingled modules, poor resistance to foundation settlement, and large stress of battery slices, etc., to overcome The effect of crack problem, strong resistance to foundation settlement, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

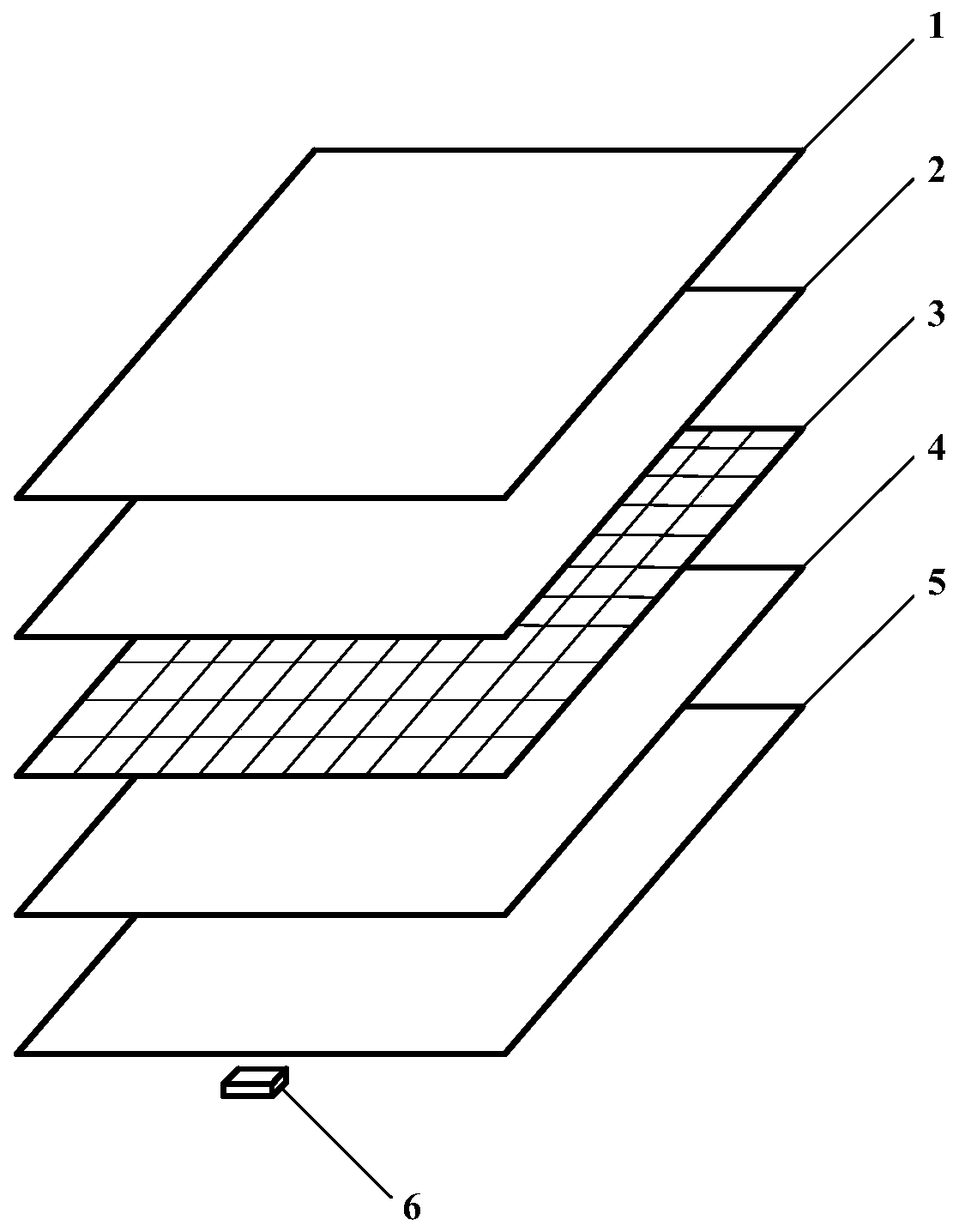

[0034] Such as figure 1 , the flexible series-parallel shingled photovoltaic module of the present invention includes a front plate 1, a front adhesive film 2, a shingled cell group 3, a rear adhesive film 4 and a back plate 5, and the shingled cell group 3 is packaged between the front plate 1 and the Between the back plates 5 , the front adhesive film 2 is arranged between the front plate 1 and the shingled cell group 3 , and the rear adhesive film 4 is arranged between the shingled cell group 3 and the back plate 5 .

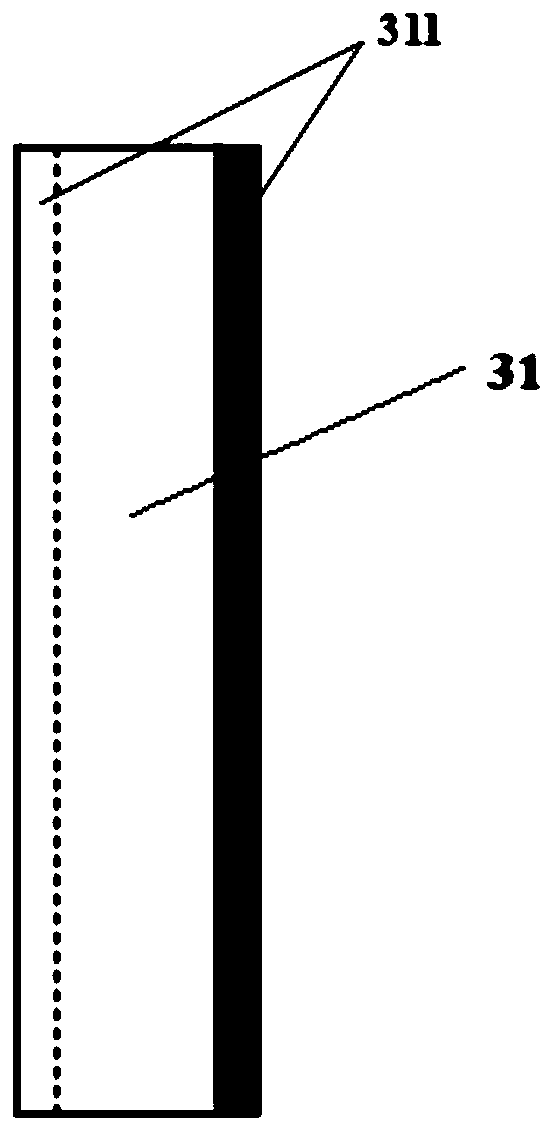

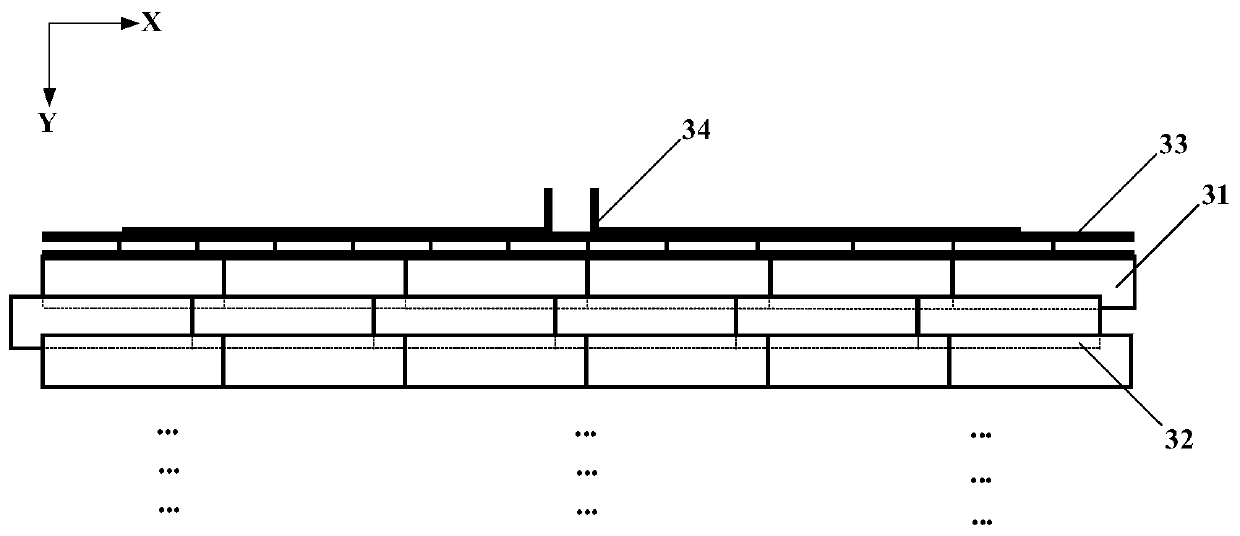

[0035] Such as figure 2 , the battery sheet 31 is cut from a common single battery sheet according to a certain ratio, and the cutting ratio can be 1 / 2, 1 / 3, 1 / 4, 1 / 5 or 1 / 6. The battery sheet 31 is a single-sided battery sheet or a double-sided battery sheet. Electrodes 311 are respectively provided on the front and back of each ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com