A kind of nano-loaded titanium series composite catalyst and its preparation method and application in polyester synthesis

A composite catalyst, titanium-based technology, applied in the synthesis of polyester, nano-loaded titanium-based composite catalyst and its preparation field, can solve the problems of scarce germanium resources, yellowish hue of polyester products, easy hydrolysis and other problems, and achieve improvement The effects of esterification and polycondensation reaction efficiency, product index stability, and strong hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

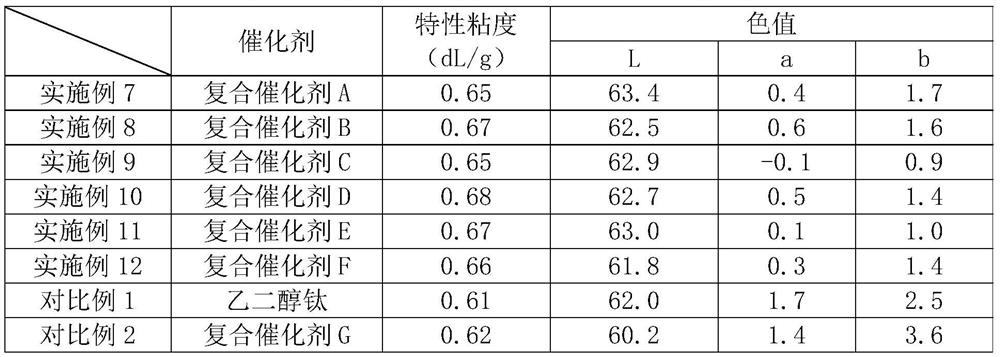

Examples

Embodiment 1-6

[0024] Example 1-6: Synthesis of nano-loaded titanium-based composite catalysts

Embodiment 1

[0026] 0.1 mol of n-butyl titanate, 0.01 mol of tetraethyl orthosilicate, 0.2 mol of lactic acid and 0.3 mol of water were dissolved in 100 ml of absolute ethanol, and stirred and mixed at room temperature for 2 hours. Then add 0.01 mol of aluminum chloride and 0.01 mol of cobalt acetate, continue stirring at room temperature for 1 hour, then heat to 50° C. and ultrasonically disperse until a gel is formed. Put the gel into an autoclave, use absolute ethanol as a supercritical medium, and dry the gel for 60 minutes under the conditions of 262° C. and 8.5 MPa to obtain a nano-supported titanium-based composite catalyst A.

Embodiment 2

[0028] 0.1 mol of tetraethyl titanate, 0.02 mol of tetraethyl orthosilicate, 0.3 mol of citric acid and 0.3 mol of water were dissolved in 100 ml of absolute ethanol, and stirred and mixed at room temperature for 2.5 hours. Then add 0.01 mol of magnesium chloride and 0.02 mol of cobalt acetate, continue to stir at room temperature for 1 hour, then heat to 40° C. and ultrasonically disperse until a gel is formed. Put the gel into the autoclave, use absolute ethanol as the supercritical medium, and dry the gel for 60 minutes under the conditions of 262° C. and 8.5 MPa to obtain nano-supported titanium-based composite catalyst B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com