Water-resistant acrylate emulsion adhesive and preparation method thereof

The technology of acrylate and methyl acrylate, which is applied in the field of water-resistant acrylate emulsion adhesive and its preparation, can solve the problems of low production efficiency and high energy consumption in the preparation process, so as to reduce the waste rate, reduce energy consumption, and improve emulsification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

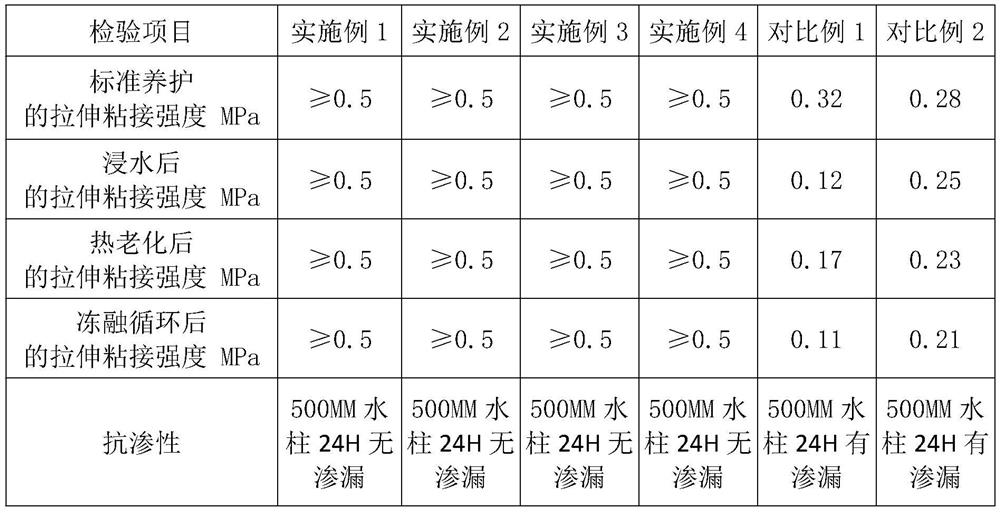

Examples

preparation example Construction

[0028] A preparation method of a water-resistant acrylic emulsion adhesive, comprising the following steps:

[0029] (1) Add polystyrene methyl methacrylate, methyl acrylate, hydroxyethyl acrylate, hydroxyethyl methacrylate, hexyl acrylate, isooctyl acrylate, and methyl methacrylate to the reactor for stirring Dissolving, the reaction temperature is 45-50°C, and the reaction time is 60-80 minutes;

[0030] (2) Add defoamer, thickener and surfactant to the reaction kettle to continue the reaction, the reaction temperature is 50-55°C, and the reaction time is 25-35 minutes;

[0031] (3) Add emulsifier and deionized water to the reaction kettle in step (2) to carry out emulsification reaction. The emulsification reaction temperature is 55-60°C. Stop heating after 25-35 minutes of emulsification reaction, and obtain a water-resistant acrylate emulsion after the end adhesive.

[0032] Since the preparation process of the existing acrylate emulsion adhesive is carried out simultan...

Embodiment 1

[0061] A water-resistant acrylate emulsion adhesive, by weight percentage, raw materials include 25% polystyrene methyl methacrylate, 8% methyl acrylate, 3% hydroxyethyl acrylate, 5% methacrylic acid Hydroxyethyl ester, 4% hexyl acrylate, 4% isooctyl acrylate, 1% methyl methacrylate, 0.5% emulsifier, 0.1% defoamer, 0.4% thickener, 1% Surfactant, the balance is deionized water. The emulsifier is sodium dodecylsulfonate and potassium dodecylbenzoate, the defoamer is polyoxypropylene glyceryl ether, the thickener is hydroxyethyl cellulose, and the surfactant is fatty alcohol polyoxyethylene ether sulfuric acid sodium.

[0062] A preparation method of a water-resistant acrylic emulsion adhesive, comprising the following steps:

[0063] (1) Add polystyrene methyl methacrylate, methyl acrylate, hydroxyethyl acrylate, hydroxyethyl methacrylate, hexyl acrylate, isooctyl acrylate, methyl methacrylate and the formula ratio to the reaction Stir and dissolve in the kettle, the reaction...

Embodiment 2

[0067] A water-resistant acrylate emulsion adhesive, by weight percentage, raw materials include 30% polystyrene methyl methacrylate, 5% methyl acrylate, 4% hydroxyethyl acrylate, 4% methacrylic acid Hydroxyethyl ester, 4% hexyl acrylate, 3% isooctyl acrylate, 1% methyl methacrylate, 0.5% emulsifier, 0.1% defoamer, 0.4% thickener, 1% Surfactant, the balance is deionized water. The emulsifier is sodium dodecyl sulfonate, the defoamer is polyoxyethylene tetraol ether and polyoxypropylene glyceryl ether, the thickener is hydroxyethyl cellulose, and the surfactant is fatty alcohol polyoxyethylene ether sodium sulfate .

[0068] A preparation method of a water-resistant acrylic emulsion adhesive, comprising the following steps:

[0069] (1) Add polystyrene methyl methacrylate, methyl acrylate, hydroxyethyl acrylate, hydroxyethyl methacrylate, hexyl acrylate, isooctyl acrylate, methyl methacrylate and the formula ratio to the reaction Stir and dissolve in the kettle, the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com