Special polymer cement coating containing inorganic powder in liquid material

A technology for cement coatings and inorganic powders, which can be used in cement coatings, carboxyl rubber coatings, coatings, etc., and can solve problems such as performance defects of polymer cement coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

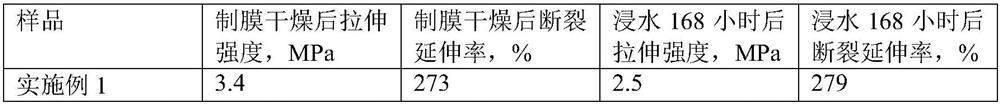

Embodiment 1

[0021] The coating of the present embodiment is made up of liquid material and powder two kinds of components, and specific proportion is as follows:

[0022] Liquid composition:

[0023] Silane-modified acrylic emulsion: 100 parts

[0024] Ground calcium carbonate powder: 90 parts

[0025] Silica powder: 30 parts

[0026] Silane: 0.4 parts

[0027] Defoamer: 0.4 parts

[0028] Wetting agent: 0.3 parts

[0029] Thickener: 0.1 to 0.2 parts

[0030] Surfactant: 1.5 parts

[0031] Powder composition:

[0032] Cement: 22 parts

[0033] Superplasticizer: 0.2 parts

[0034] The silane-modified acrylic emulsion of this embodiment is purchased from the market, and its glass transition temperature is lower than 10 degrees Celsius.

[0035] The preferred average particle size of ground calcium carbonate powder in the present embodiment is less than 15 microns.

[0036] In this example, the silicon dioxide powder was purchased from the market with a particle size of 325 mesh. ...

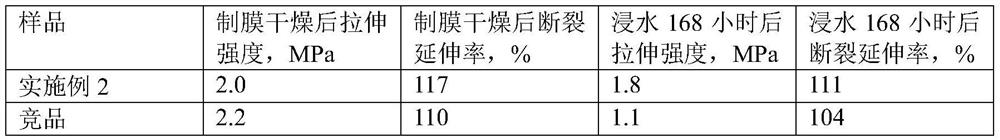

Embodiment 2

[0048] The coating of the present embodiment is made up of liquid material and powder two kinds of components, and specific proportion is as follows:

[0049] Liquid composition:

[0050] Styrene-butadiene emulsion containing carboxylic acid groups: 100 parts

[0051] Ground calcium carbonate powder: 90 parts

[0052] Silica powder: 35 parts

[0053] Epoxy silane: 0.4 parts

[0054] Defoamer: 0.4 parts

[0055] Wetting agent: 0.3 parts

[0056] Thickener: 0.1 parts

[0057] Powder composition:

[0058] Cement: 15 parts

[0059] High-efficiency water reducer: 0.2 parts of the styrene-butadiene emulsion containing carboxylic acid groups in this embodiment is purchased from the market, and its glass transition temperature is lower than -5 degrees Celsius.

[0060] The preferred average particle size of ground calcium carbonate powder in the present embodiment is less than 15 microns.

[0061] In this example, the silicon dioxide powder was purchased from the market with ...

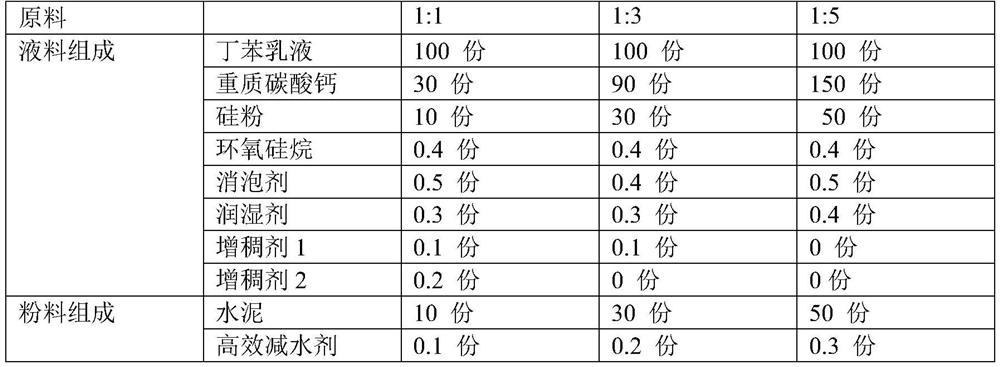

Embodiment 3

[0073] The coating in this example is composed of liquid material and powder material, and the mass ratios of polymer and inorganic material in the final formulation are 1:1, 1:3 and 1:5, respectively. The specific ratio is as follows:

[0074]

[0075] The styrene-butadiene emulsion of this embodiment is purchased from the market, has carboxylic acid groups, and its glass transition temperature is lower than -10 degrees Celsius.

[0076] The preferred average particle size of ground calcium carbonate powder in the present embodiment is less than 15 microns.

[0077] In this example, the silicon dioxide powder was purchased from the market with a particle size of 325 mesh.

[0078] In this embodiment, epoxy silane is purchased from the market.

[0079] In this example, the defoamer was purchased from BASF.

[0080] The wetting agent in this example is a water-based wetting and dispersing machine purchased from Hemings.

[0081] Both thickeners in this example are purcha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com