Preparation method of cubic micro/nano cuprous oxide powder

A cuprous oxide, micro-nano technology, which is applied in the preparation of high-purity ultra-fine cuprous oxide powder and the preparation of cubic micro-nano cuprous oxide powder, can solve the problems of high raw material cost, high local pH value, explosiveness, etc., and achieve The process is easy to control, the specific surface area is small, and the bulk density is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

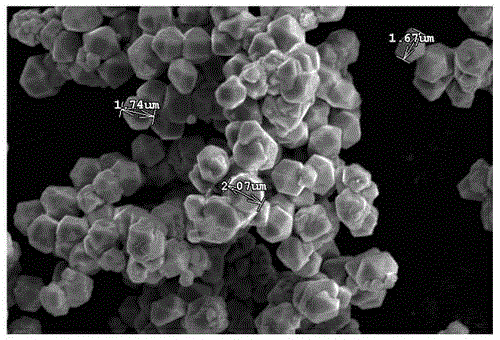

Embodiment 1

[0023] (1) Mix the acidic etching waste liquid and alkaline etching waste liquid recovered from printed circuit boards in a certain proportion, control the pH of the copper liquid after mixing at 3.0, and prepare Cu by concentrating or replenishing water. 2+ Concentration is the copper liquid A of 100g / L;

[0024] (2) Dissolve sodium carbonate and sodium sulfite in water respectively, and prepare sodium carbonate solution B with a concentration of 200g / L and sodium sulfite solution C with a concentration of 200g / L;

[0025] (3) Take 500mL of solution A, stir and preheat to 50°C, add 0.8g of composite dispersant, the composite dispersant is gelatin and sodium dodecylbenzenesulfonate with a mass ratio of 1:1;

[0026] (4) Quickly add 750mL solution C to the solution in step (3), slowly add solution B dropwise, control the pH value of the reaction solution to 4.5, continue to stir and heat to 90°C;

[0027] (5) After 2 hours of reaction, filter the collected reaction final produ...

Embodiment 2

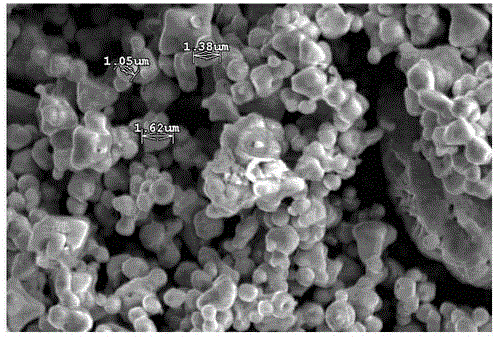

[0029] (1) Mix the acidic etching solution recovered from the printed circuit board with the alkaline etching waste solution in a certain proportion, control the pH of the mixed copper solution at 3.0, and prepare Cu by concentrating or replenishing water. 2+ Concentration is the copper liquid A of 120g / L;

[0030] (2) Dissolve sodium carbonate and sodium sulfite in water respectively to prepare sodium carbonate solution B with a concentration of 210g / L and sodium sulfite solution C with a concentration of 200g / L.

[0031] (3) Take 500mL of solution A, stir and preheat to 45°C, add 0.5g of composite dispersant, the composite dispersant is gelatin and sodium dodecylbenzenesulfonate with a mass ratio of 1:1;

[0032] (4) Quickly add 700mL solution C to the solution in step (3), slowly add solution B dropwise, control the pH value of the reaction solution to 4.5, continue to stir and heat to 83°C;

[0033] (5) After reacting for 2.5 hours, filter the collected reaction final pro...

Embodiment 3

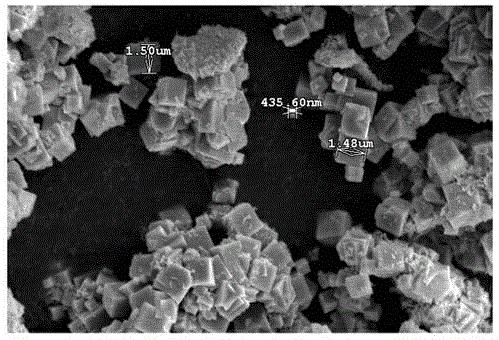

[0035] (1) Mix the acidic etching solution recovered from the printed circuit board with the alkaline etching waste solution in a certain proportion, control the pH of the mixed copper solution at 2.5, and prepare Cu by concentrating or replenishing water. 2+ Concentration is copper liquid A of 90g / L;

[0036] (2) Dissolve sodium carbonate and sodium sulfite in water respectively, and prepare sodium carbonate solution B with a concentration of 190g / L and sodium sulfite solution C with a concentration of 200g / L;

[0037] (3) Take 500mL of solution A, stir and preheat to 50°C, add 1g of composite dispersant, the composite dispersant is gelatin and sodium dodecylbenzenesulfonate with a mass ratio of 1:1;

[0038] (4) Quickly add 800mL solution C to the solution in step (3), slowly add solution B dropwise, control the pH of the reaction solution to 3.5, continue to stir and heat to 100°C;

[0039](5) After reacting for 4 hours, filter the collected reaction final product, wash it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com