Method and device for manufacturing cold-rolled high-strength steel

A high-strength steel and finishing rolling technology, applied in the field of manufacturing cold-rolled high-strength steel, can solve the problems of low-temperature coiling temperature fluctuations, unguaranteed cold rolling stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

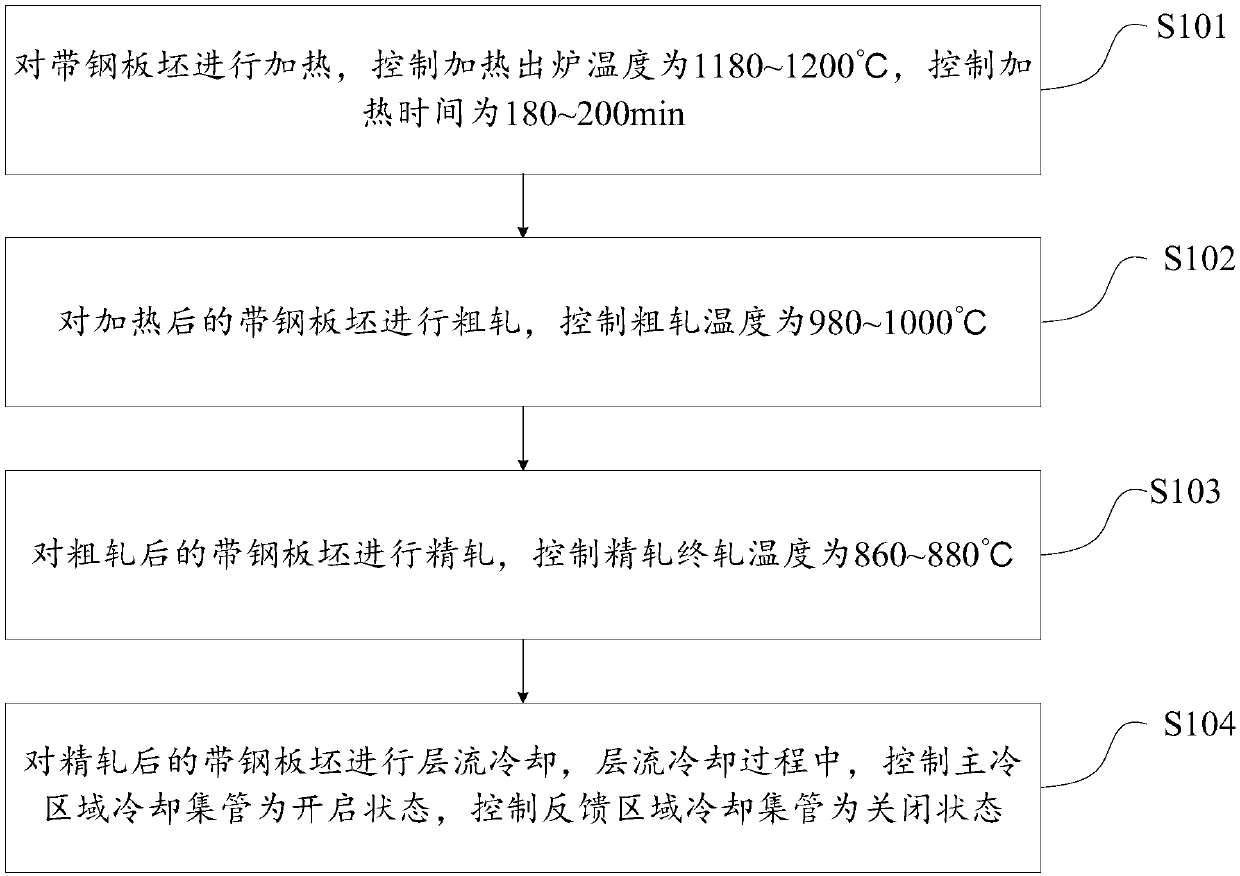

[0032] This embodiment provides a method for manufacturing cold-rolled high-strength steel, such as figure 1 As shown, the method includes:

[0033] S101, heating the strip steel slab, controlling the heating temperature to be 1180-1200°C, and controlling the heating time to be 180-200min;

[0034] In this step, the strip steel slab is heated by fast firing and low-temperature tapping technology. In order to comprehensively consider the fayalite phase Fe 2 SiO 4 The formation and thickness of the formation, control the heating temperature to 1180-1200°C, preferably: 1190-1200°C; control the heating time to 180-200min, preferably 185-195min. Wherein, the mass percentage of each component of the strip steel slab includes: C: 0.08-0.13%; Si: 1.1-1.4%; Mn: 1.4-2.0%; Al: 0.02-0.065%; P≦0.020%.

[0035] S102, performing rough rolling on the heated strip steel slab, controlling the rough rolling temperature to be 980-1000°C;

[0036] Then semi-continuous rough rolling is carried ...

Embodiment 2

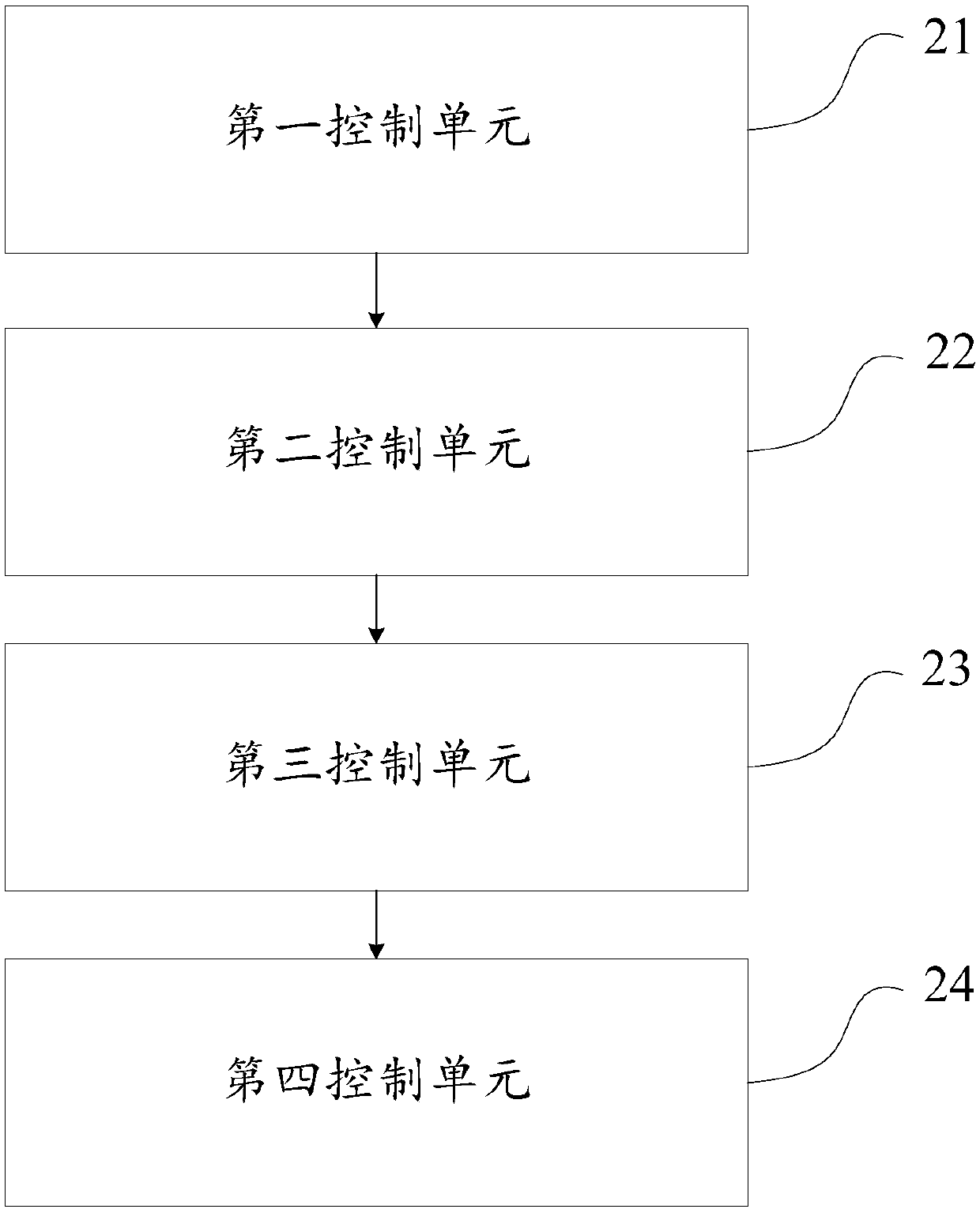

[0048] Corresponding to Embodiment 1, this embodiment provides a device for manufacturing cold-rolled high-strength steel, such as figure 2 As shown, the device includes: a first control unit 21, a second control unit 22, a third control unit 23 and a fourth control unit 24; wherein,

[0049] The strip steel slab is heated by fast firing and low-temperature tapping technology, in order to comprehensively consider fayalite phase Fe 2 SiO 4 The first control unit 21 is used to control the heating and tapping temperature to be 1180-1200°C, preferably 1190-1100°C when heating the strip steel slab, and to control the heating time to be 180-200min, preferably The ground is 185 ~ 195min.

[0050] Wherein, the mass percentage of each component of the strip steel slab includes: C: 0.08-0.13%; Si: 1.1-1.4%; Mn: 1.4-2.0%; Al: 0.02-0.065%; P≦0.020%.

[0051] In order to reduce the generation of red rust in the rolling process and ensure the finish rolling strip piercing speed, the sec...

Embodiment 3

[0061] In actual application, when manufacturing cold-rolled high-strength steel CR420 / 780DP according to the method provided in Embodiment 1 and the device provided in Embodiment 2, the specific implementation is as follows:

[0062] Here, the mass percentage of each component of the strip steel slab includes: C: 0.08-0.10%; Si: 1.1-1.2%; Mn: 1.9-2.0%; Al: 0.02-0.06%; P≦0.020%.

[0063] The strip steel slab is heated by fast firing and low-temperature tapping technology, in order to comprehensively consider fayalite phase Fe 2 SiO 4 The formation and thickness of the formation, control the heating temperature to 1198 ℃; control the heating time to 192min.

[0064] Then semi-continuous rough rolling is carried out on the heated strip slab. In order to reduce the generation of red rust in the rolling process and ensure the strip piercing speed of finish rolling, the exit temperature of rough rolling is controlled at 986°C.

[0065] Then use the finish rolling stand to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com