Adsorption type heat-storage electric-warming method and device thereof

An electric heating and adsorption-type technology is applied in the field of adsorption-type thermal storage electric heating methods and devices thereof to achieve the effects of system safety, reliability and high thermal storage density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

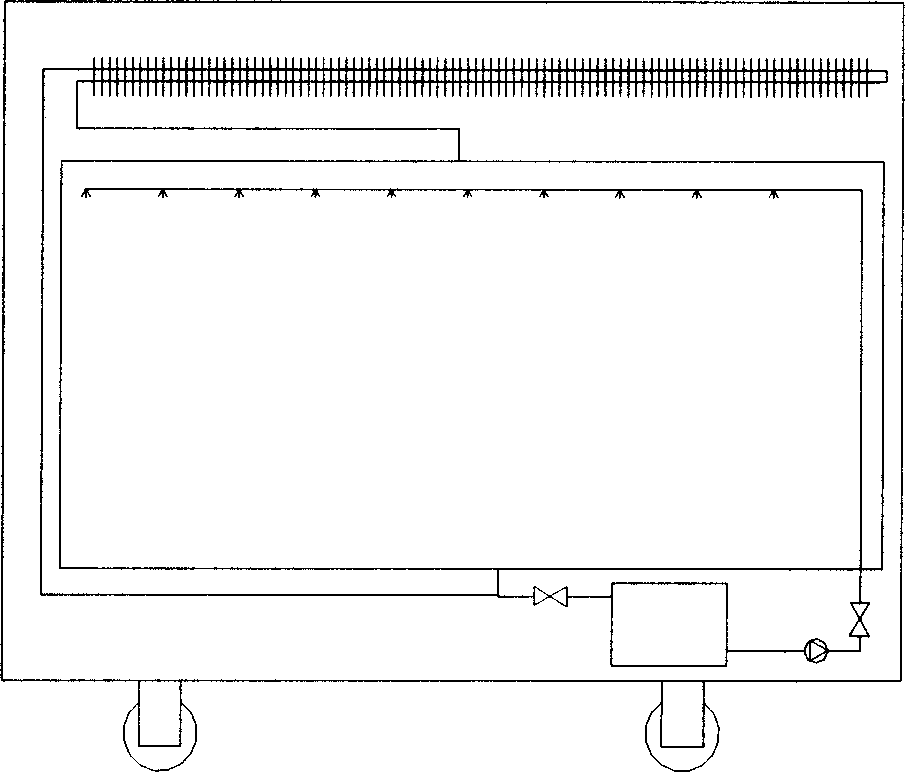

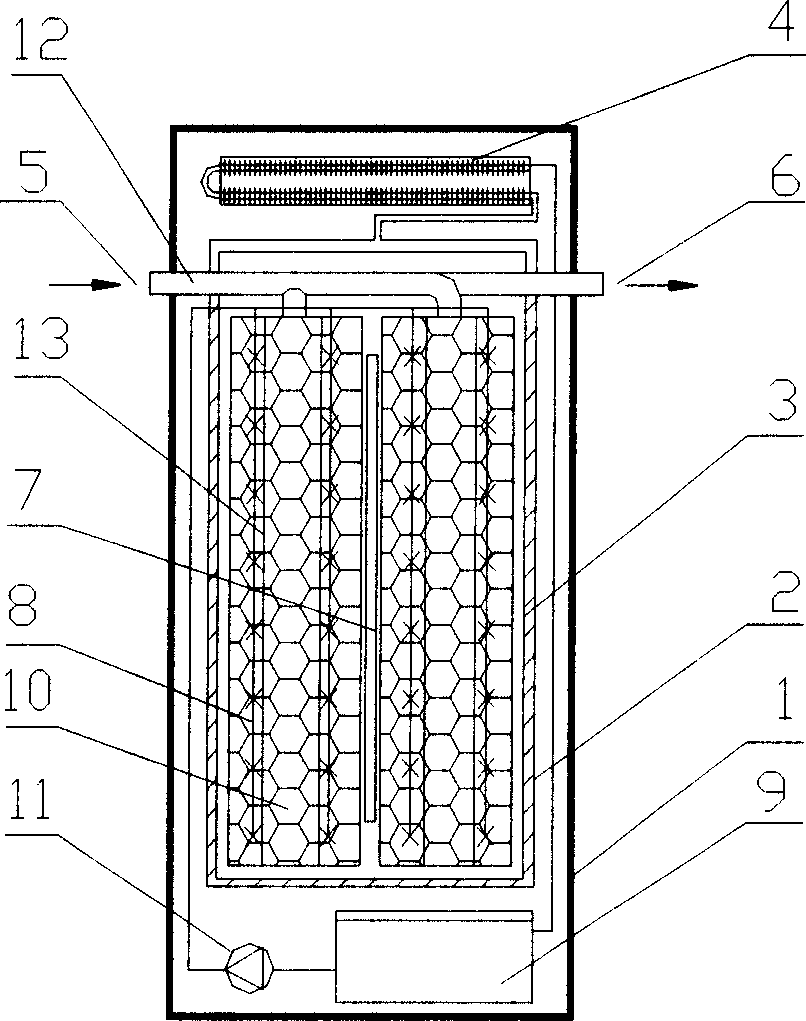

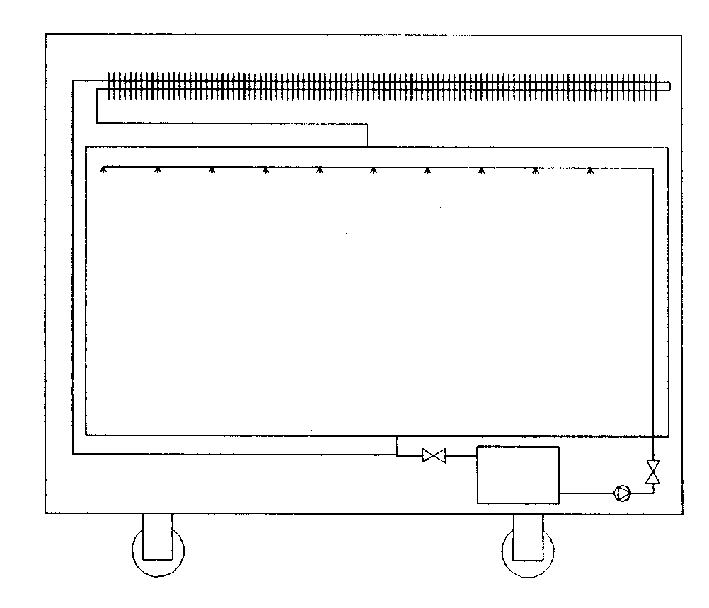

[0021] At night, when the electricity price drops, the device starts to desorb the energy storage. First, the electric heating plate 7 is energized to start heating the composite adsorption heat storage medium 10, that is, the adsorbent. When the adsorbent is heated to 150 to 200° C., the valve between the adsorber 2 and the condenser 4 is opened, and the adsorbate (such as water) It begins to desorb from the adsorbent and is condensed in condenser 4 before being stored in liquid reservoir 9. Since the desorption process is an endothermic process, electrical energy is stored. In this process, the heat released by the condenser 4 is sent to the room by the air duct 12 as the night heating of the building. After the desorption of the adsorbate is completed, the electric heating plate 7 is turned off, and the heat storage process ends.

[0022] During the day, the electricity price rises, at which time the adsorption heating process begins. The valve between the liquid reservo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com