Liquid material storage device

A liquid material and material storage technology, applied in the field of liquid material storage, can solve the problems of unstable chemical composition, insufficient liquid phase purity, liquid material deterioration, etc., and achieves good gas-liquid phase separation effect, simple structure, and prevents liquid The effect of bit too high or too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

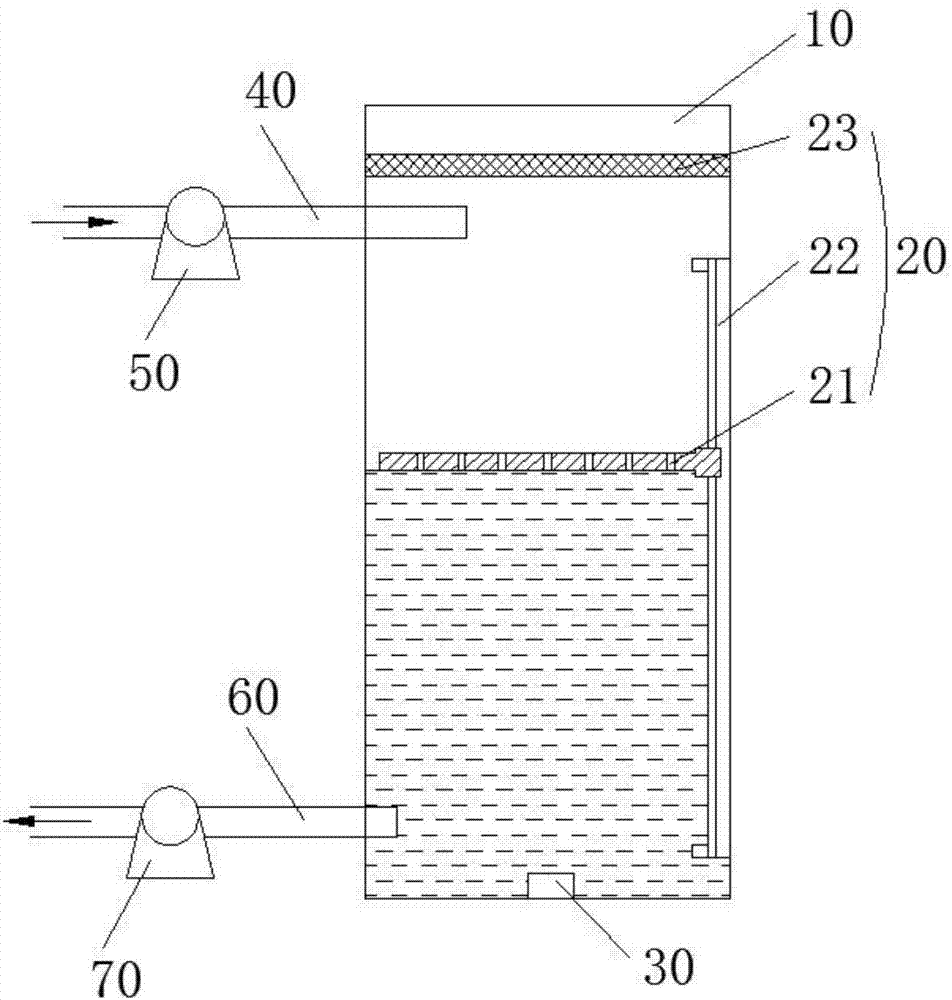

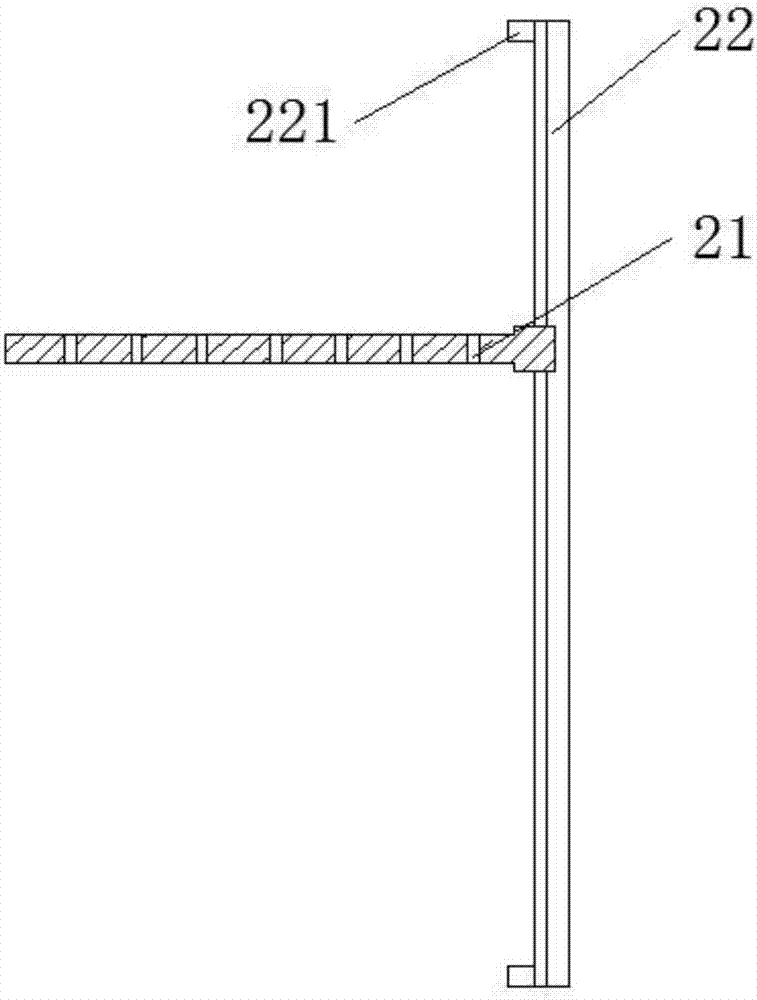

[0022] see figure 1 and figure 2 . figure 1 It is a structural schematic diagram of the liquid material storage device of the present invention. figure 2 is a side view of the buffer plate and buffer rail. The liquid material storage device of the present invention comprises a material storage tank 10, the upper part and the lower part of the material storage tank 10 are respectively provided with a liquid material inlet and a liquid material outlet; the said material storage tank 10 is provided with a buffer assembly 20; The buffer assembly 20 includes a buffer plate 21 and a buffer guide rail 22, the buffer guide rail 22 is vertically arranged on the inner wall of the storage tank 10, and the buffer plate 21 is slidably arranged on the buffer guide rail 22; A plurality of air holes are provided on the plate 21 .

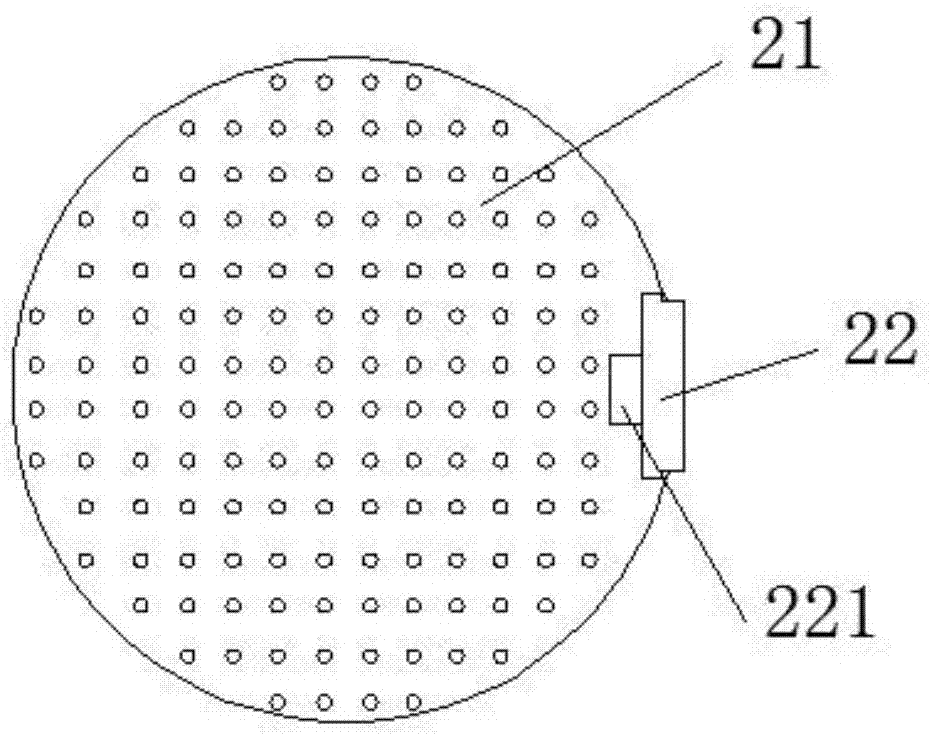

[0023] see image 3 , image 3 is the top view of the buffer plate and the buffer rail. The buffer assembly 20 of this embodiment is also preferably provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com