Method for controlling fluctuation of liquid level of crystallizer

A technology for liquid level fluctuation and crystallization control, applied in the field of metallurgy, can solve problems such as liquid level fluctuation, and achieve the effect of maintaining liquid level and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Use the method of increasing the immersion depth.

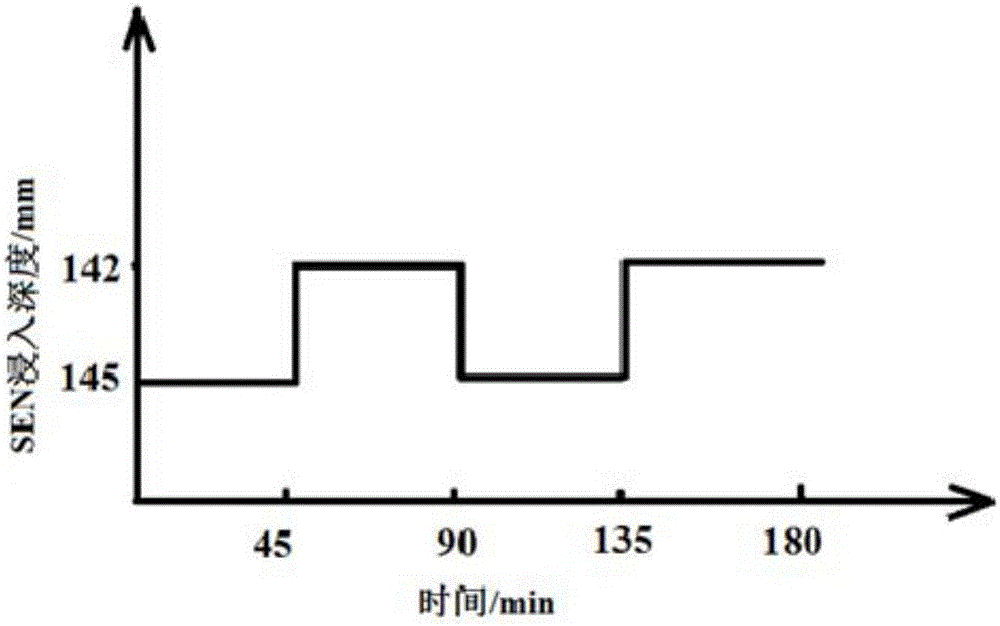

[0043] The specific operation steps are as follows: when continuous casting of 10 batches of ultra-low carbon steel is carried out, the water change port operation is performed in the 6th furnace. The casting time of each furnace is 30 minutes. When the casting section is 230mm×1600mm, the casting speed is 1.2m / min. The depth is 145mm, and the fluctuation range of immersion depth is in the range of 135-155mm.

[0044] When casting for 45 minutes, the immersion depth was increased by 3 mm, and the immersion depth was 142 mm; when casting was 90 minutes, the immersion depth was reduced to 145 mm for casting; when casting 135 minutes, the immersion depth was increased by 3 mm, and the immersion depth was 142 mm; when casting 180 minutes, the water port was changed in the sixth furnace operate.

example 2

[0046] Use the method of lowering the immersion depth.

[0047] When continuous casting of 10 heats of ultra-low carbon steel is carried out, the water outlet operation shall be carried out in the 6th heat. The casting time of each heat is 30 minutes. The depth fluctuation range is in the range of 145-165mm.

[0048] When casting for 45 minutes, the immersion depth is increased by 3mm, and the immersion depth is 152mm; when casting is 90min, the immersion depth is adjusted to 155mm for casting; when casting is 135min, the immersion depth is increased by 3mm, and the immersion depth is 152mm; when casting is 180min, it is carried out in the sixth furnace Change water port operation.

[0049] It is not difficult to see that when performing a casting operation task, the depth adjustment maintains a uniform adjustment trend, that is, any one of the immersion depth adjustment or the lower immersion depth adjustment is adopted; that is, the immersion depth is restored in a period o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com