As cast condition large gradient material preparation method and utilization device thereof

A gradient material, bulk technology, applied in the field of materials, can solve problems such as few literatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

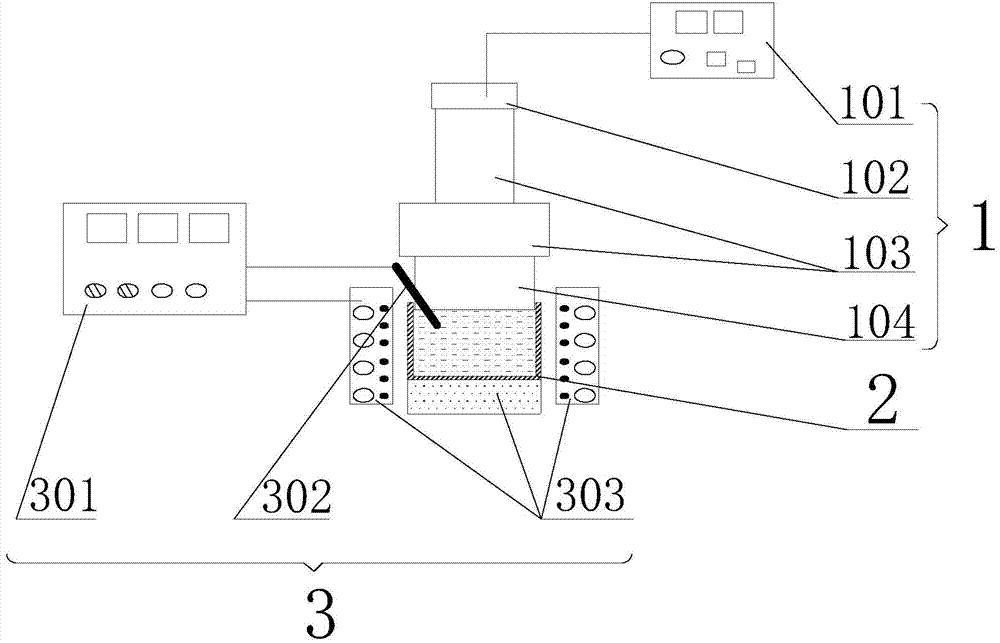

[0058] Such as figure 1 As shown, the device for preparing as-cast bulk gradient material in the present invention includes an ultrasonic generating device 1, a casting mold 2 and a temperature control system 3, and the ultrasonic generating device 1 includes an ultrasonic generating controller 101, a transducer 102, and a horn 103. Ultrasonic tool head 104, the ratio of the diameter of the ultrasonic tool head 104 to the inner diameter of the mold 2 is 0.9; the temperature control system 3 includes a temperature control measuring instrument 301, a thermocouple 302 and a heating / cooling system 303, the The thermocouple 302 is located in the casting mold 2, the temperature control measuring instrument 301 receives the signal of the thermocouple 302, measures the temperature of the slurry in the casting mold 2, and the temperature control measuring instrument 301 controls the heating / cooling The system 303 heats or cools the slurry in the mold 2 .

[0059] Utilizing the device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com